International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Description

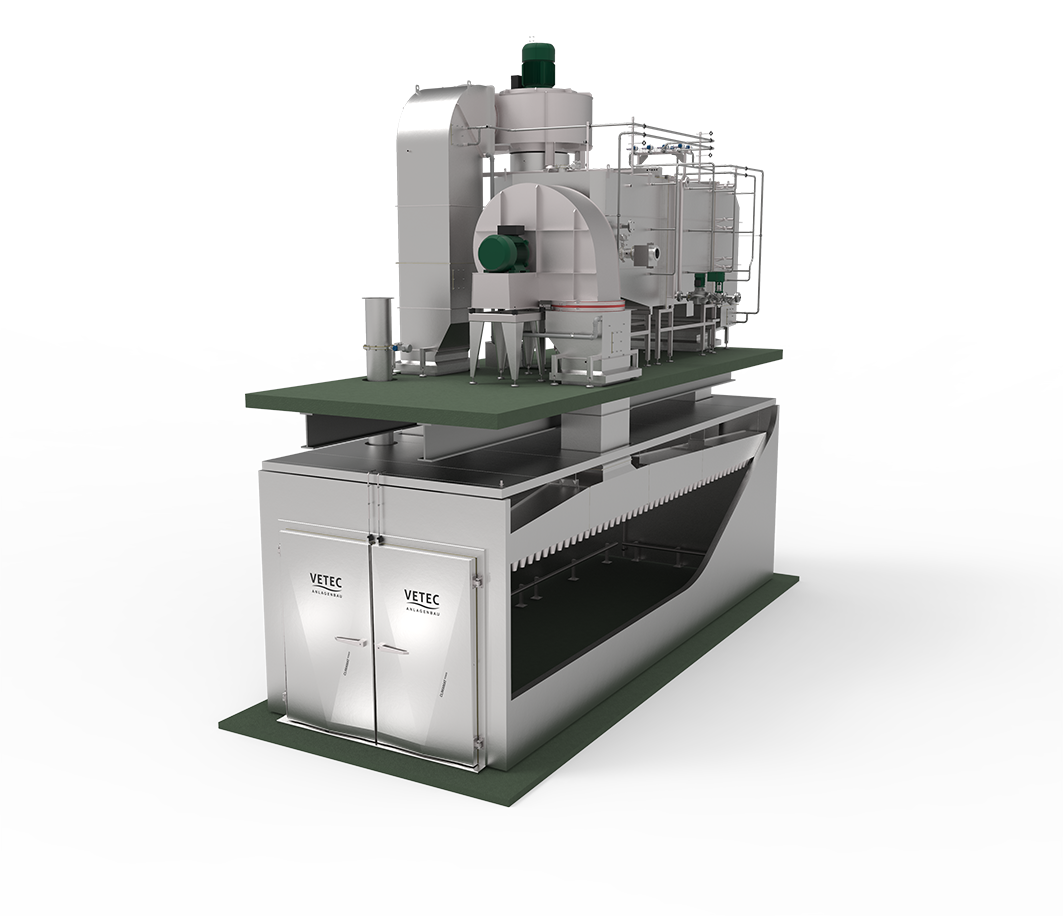

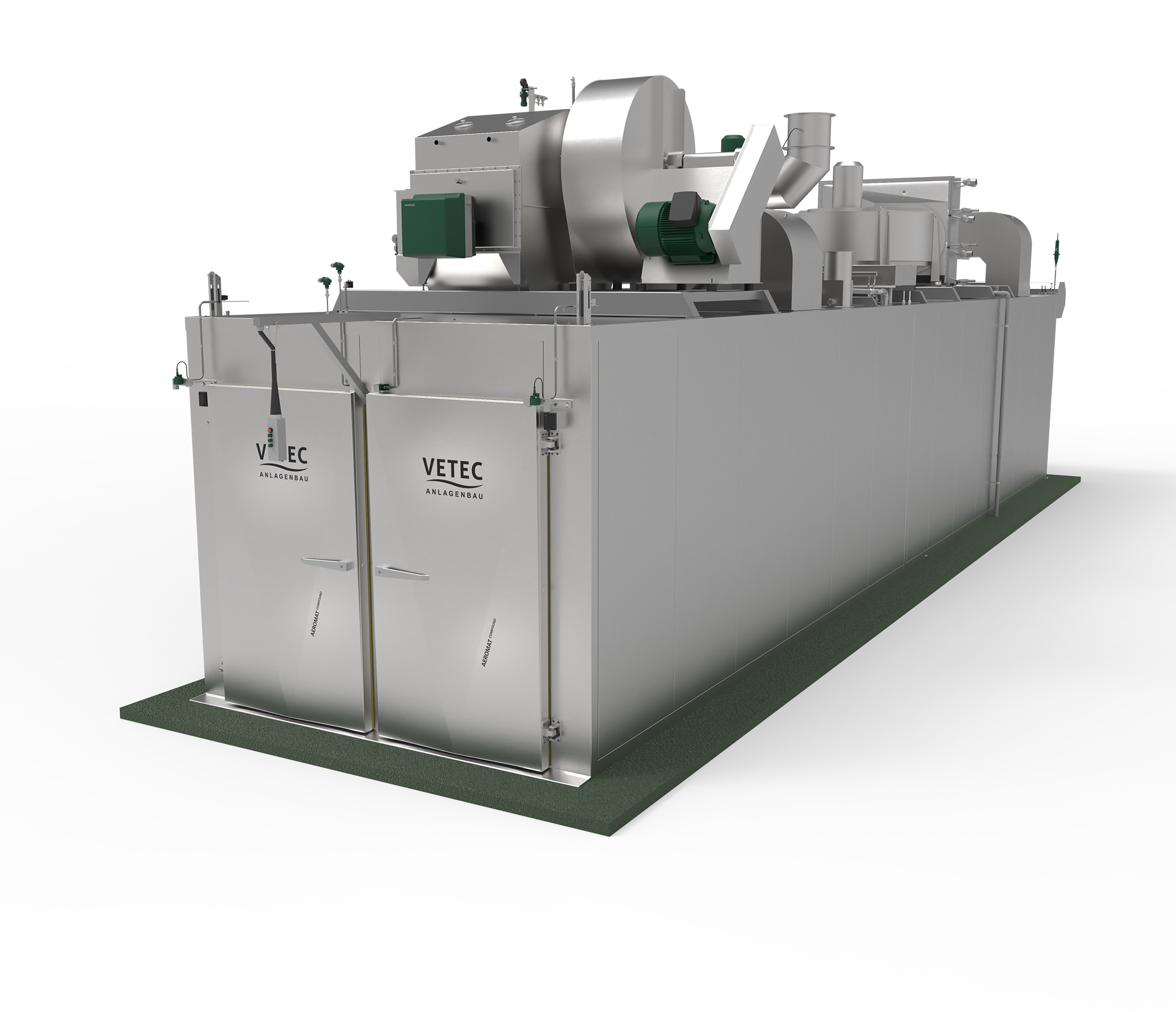

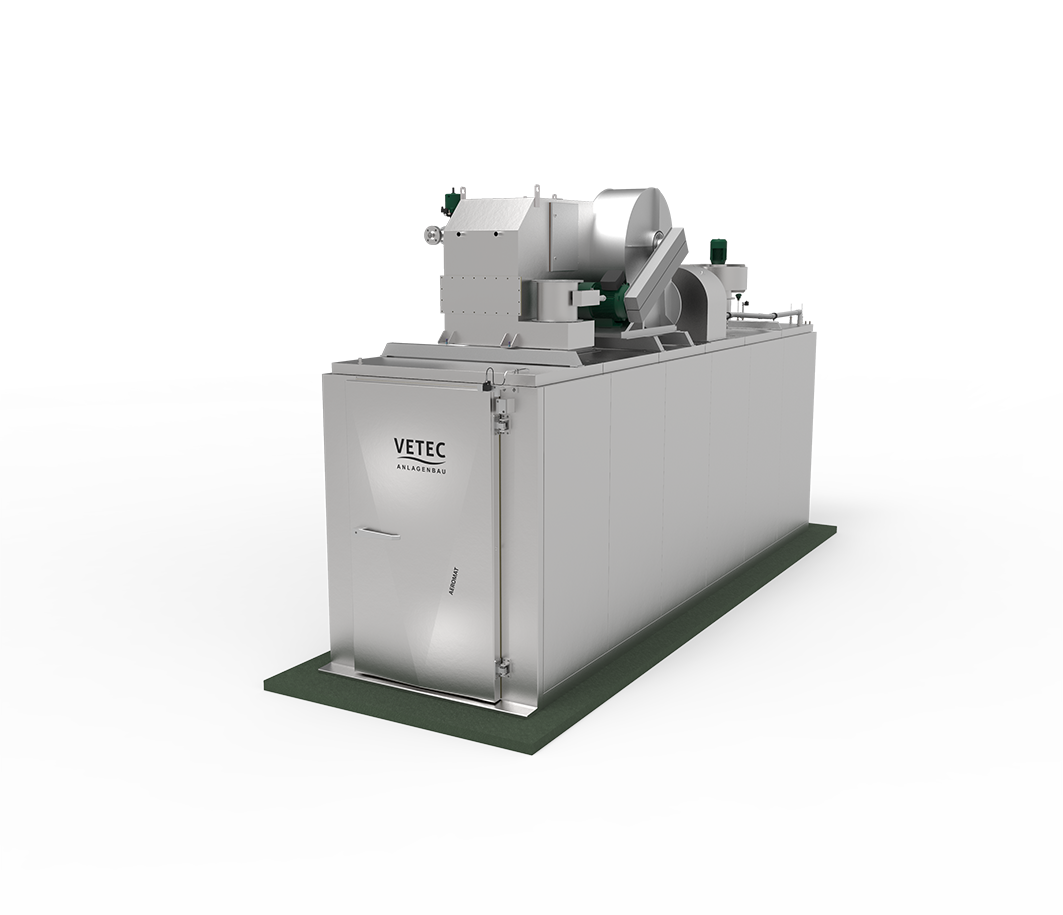

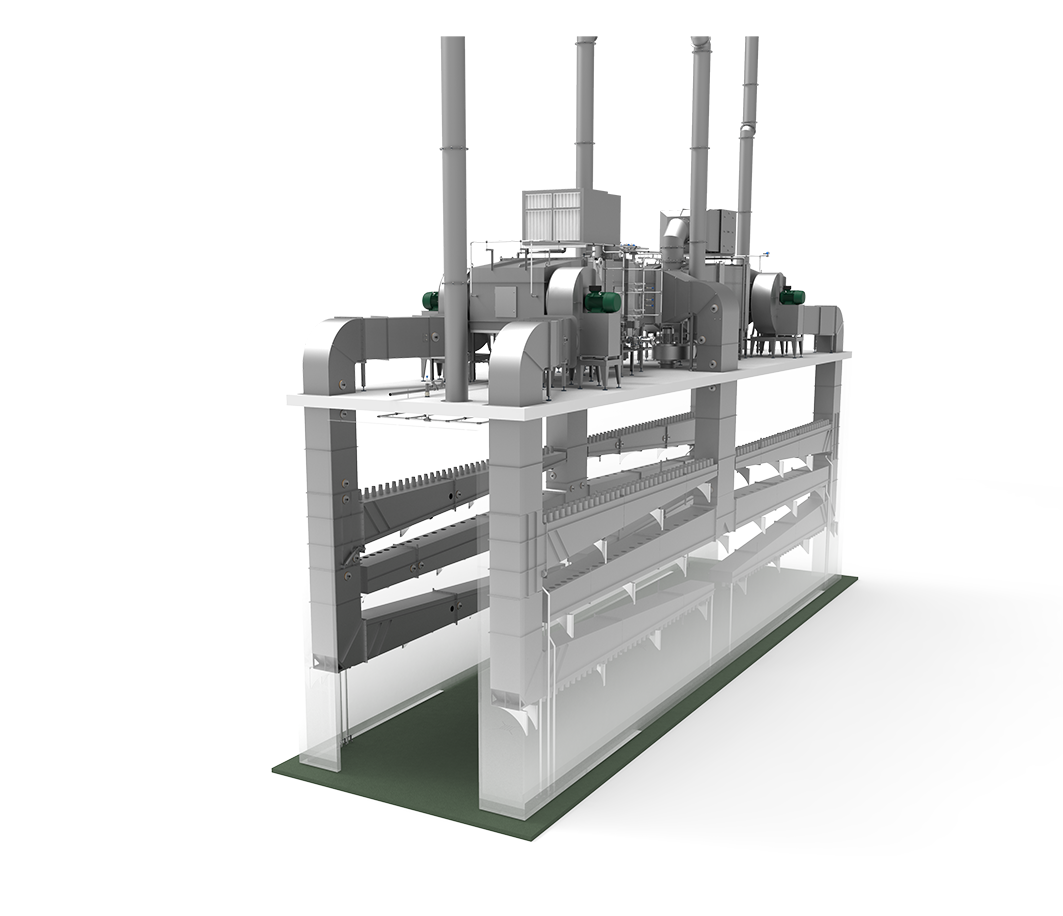

The VETEC CLIMAMAT DEFROST thaws out deep-frozen food exceptionally gently and with a focus on quality. Entire blocks or individual products: Thawing with air at a very high relative humidity ensures an even and hygienic process, regardless of whether open or packed products are involved. The process is reliable and stable and the products maintain their delicate structure without dry edges and with consistent colouring. Temperature sensitive products can be thawed exceptionally gently.

In order to guarantee a product-friendly and economical process, controlled process management is necessary. By means of interval and temperature automation depending on the surface temperature the CLIMAMAT DEFROST guarantees an optimal thawing result. Sensors on the product record core and surface temperature and are used for a control system optimally adapted to your product. In this way, partial overheating is avoided while the defrosting process is accelerated. Due to the high air humidity during the process, weight losses can also be kept extremely low. The risk of cross-contamination with germs via the air is eliminated and humidification with steam instead of water avoids additional germ entry. In addition, the CLIMAMAT DEFROST can also be used as a cold store.