International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Description

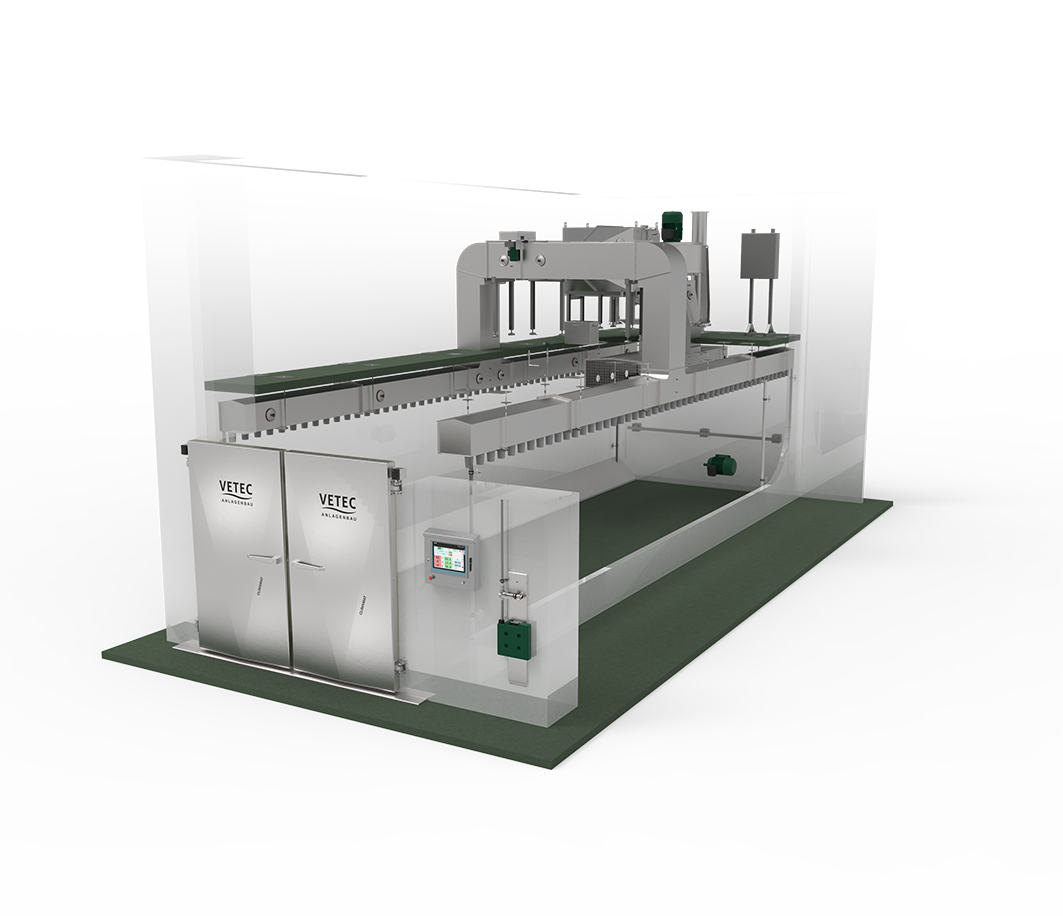

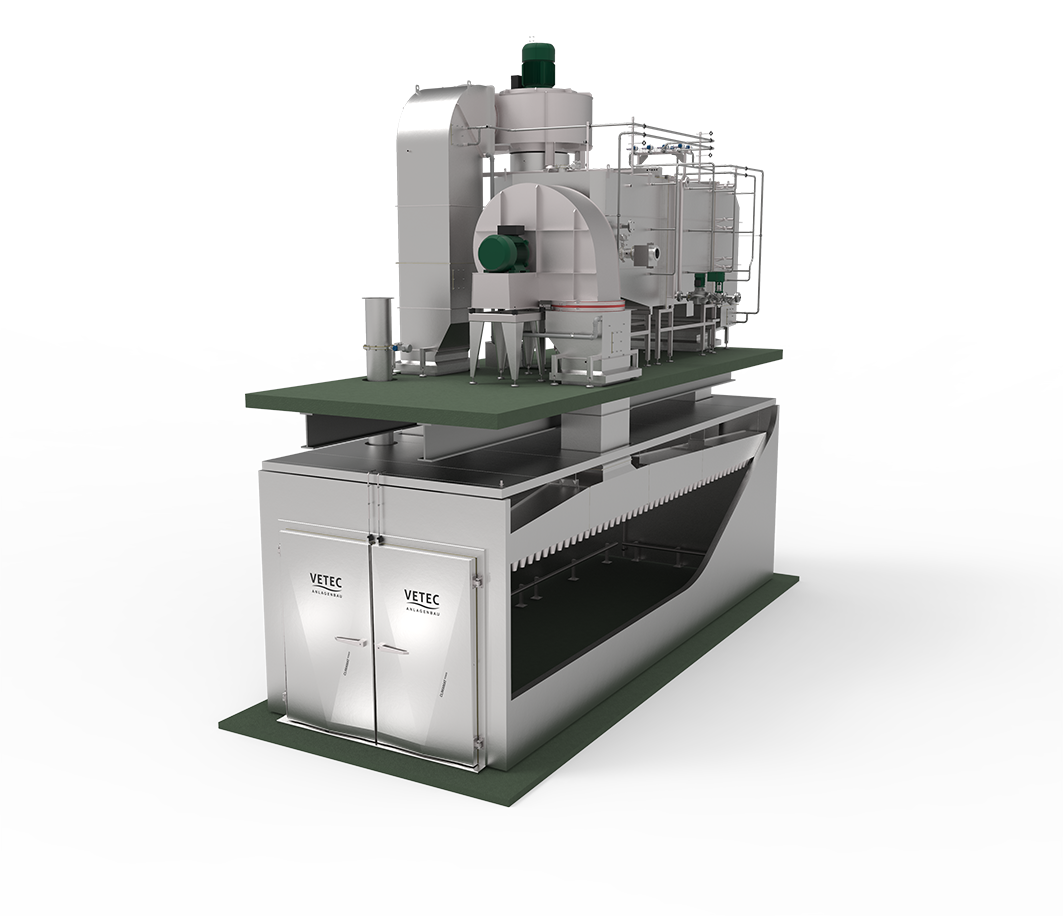

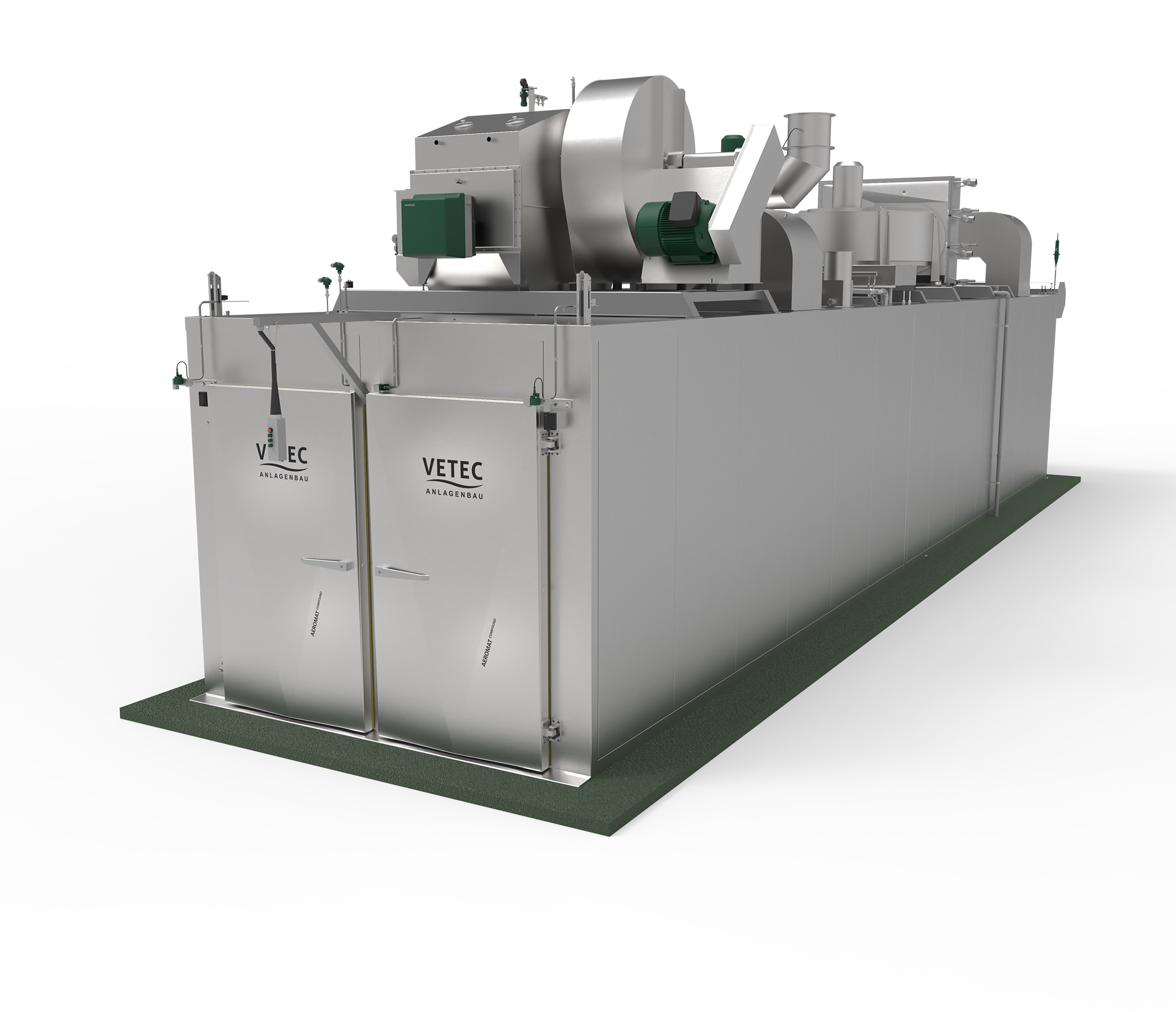

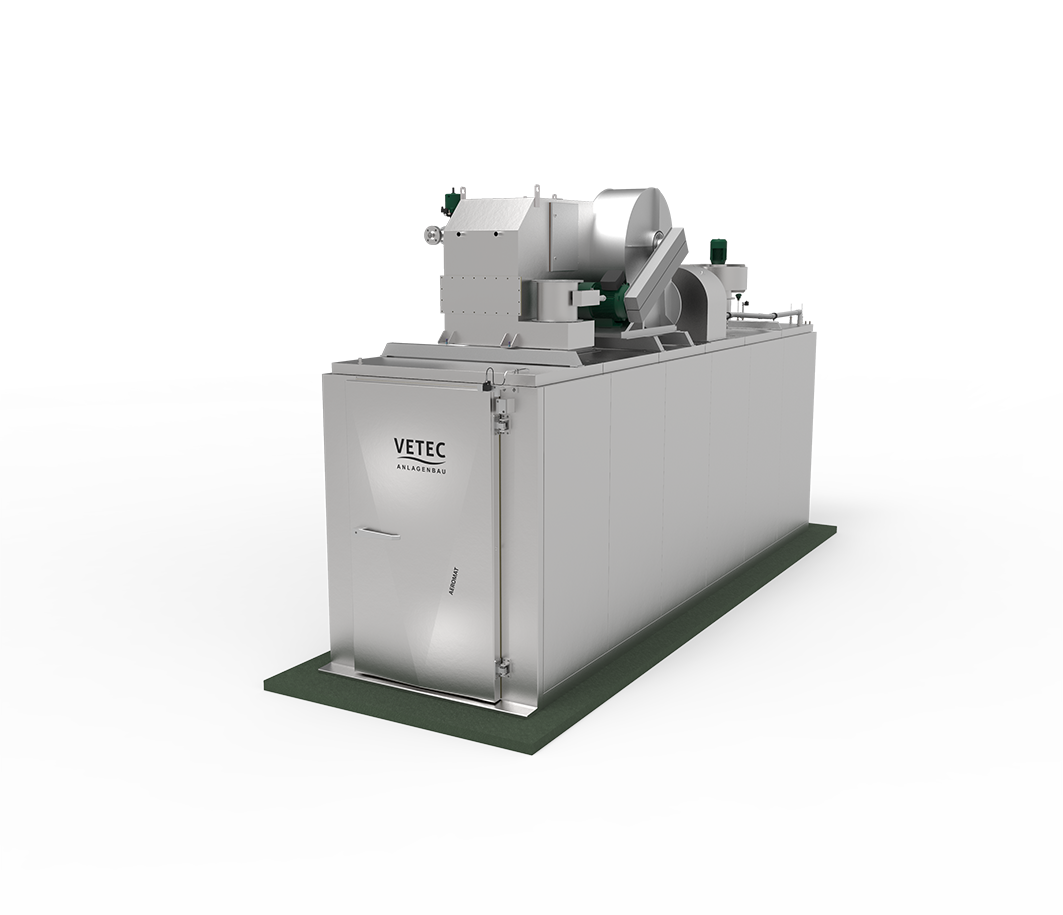

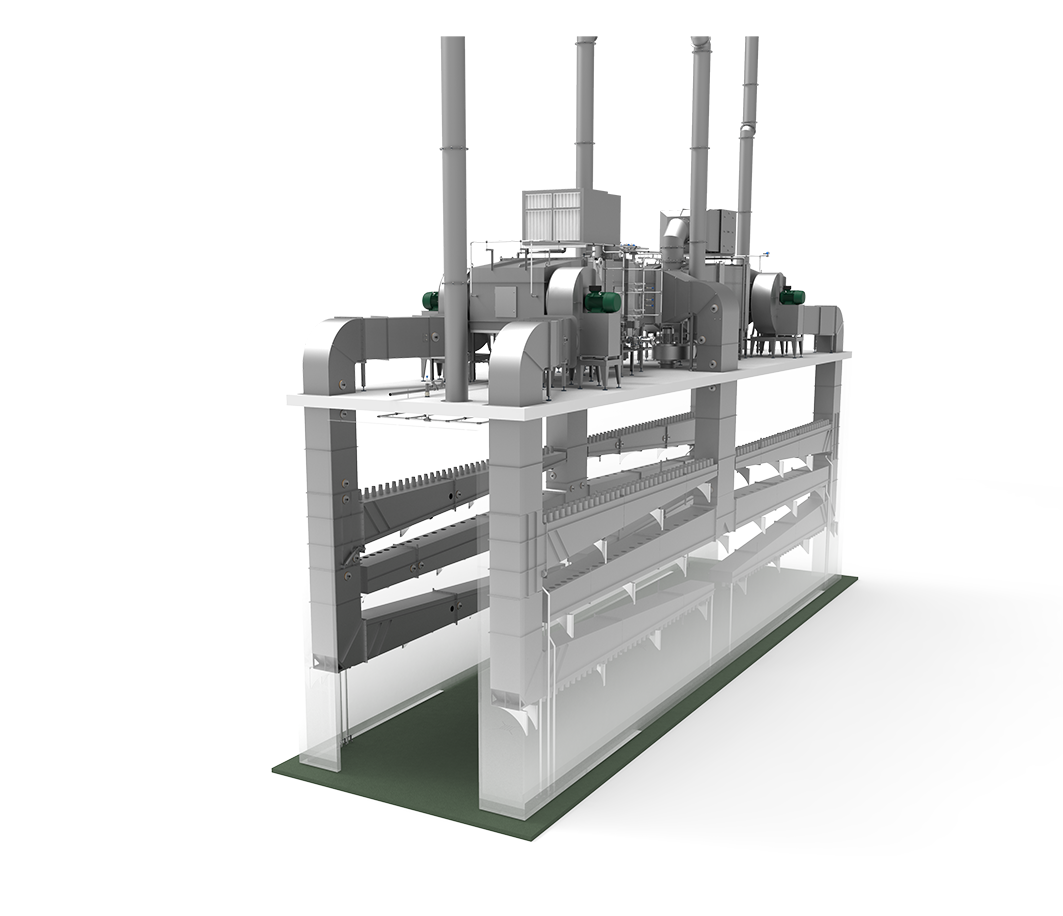

Maturing, drying and smoking of Salami und raw cured meats: the CLIMAMAT CROSS climatic maturing installation sets standards in pre-maturing. The Installations for maturing and cold smoking are equipped with individual air flow systems and can be fitted customer specific to your products, your production capacities and your local conditions.

The cross-flow system for maturing and cold smoking enables an immense increase in yield at unchanged room volume without any loss in quality thanks to movable inblow ducts. The unique, uniform and dynamic flow through the grids, which are arranged one above the other with the smallest possible spacing, ensures perfect, reproducible results of lying products.

This installation does not only convince by several application possibilities, such as drying, smoking, fermenting or cooling. Even with densely packed products, consistent results are achieved by the individual air flow, which achieves a continuous quality. The racks, which can be up to 7m high, can optionally be automatically transported into the installation by AGV and weighed.