International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

More than just a mixer – the KS Mixing Centre 600 V

More than just a mixer – the KS Mixing Centre 600 V

Description

High-end solution for modern production processes

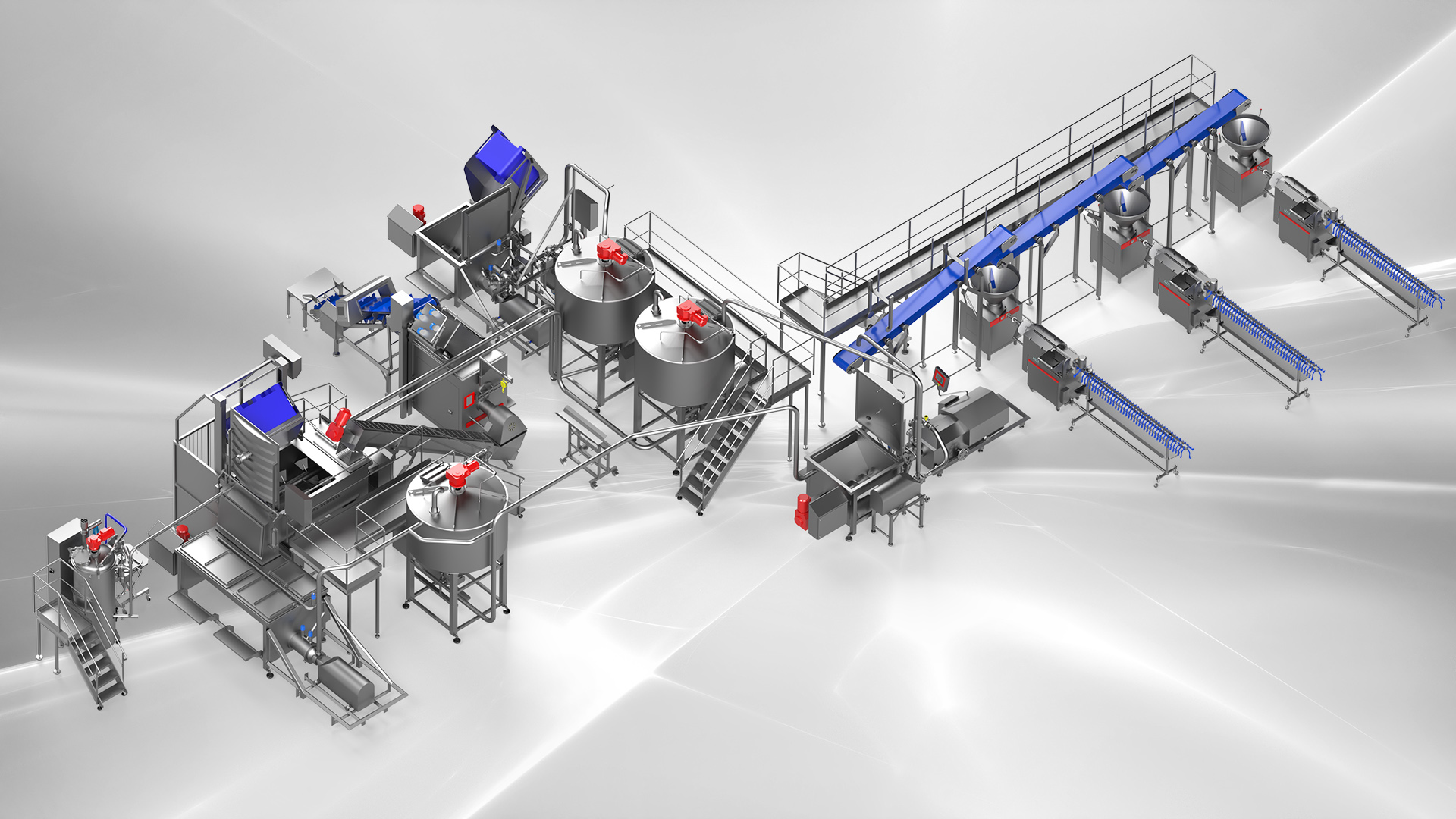

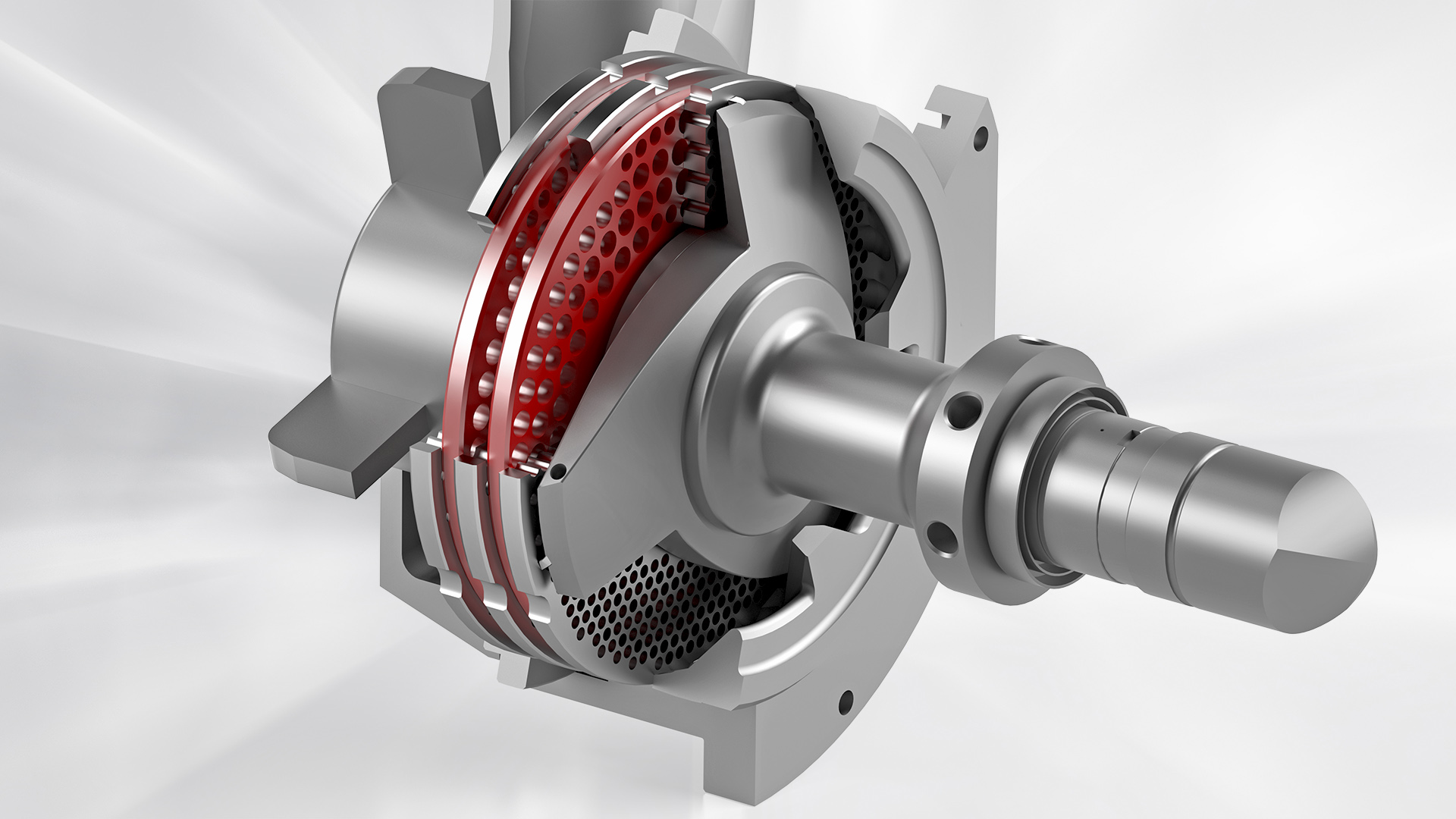

The KS Mixing Centre 600 V from KARL SCHNELL is far more than just a conventional mixer – it is an innovative process centre for the flexible, efficient, and high-quality processing of a wide variety of food products. Developed for the demanding requirements of the food industry, this system combines the advantages of a low-shear mixer with an integrated high-shear emulsifier, fed by a pump directly below the mixing vessel. This opens up completely new process possibilities – from gentle premixing to precise emulsification under high vacuum.

Innovative functionality meets maximum flexibility

The KS Mixing Centre 600 V is specially designed for the processing of highly viscous and shear-sensitive products under vacuum. The combination of low-shear mixing and high-shear emulsifying enables products to be processed particularly homogeneously, gently, and efficiently. Dry substances can be effectively dispersed in liquids – without clumping and with high uniformity.

Flexibly selectable process paths:

- Conventional further processing: The mixture is transferred to a connected buffer tank and continuously fed to the downstream production unit.

- Direct emulsification: The integrated product pump conveys the premix directly under vacuum to the emulsifier, which processes the product into a homogeneous emulsion using the high-shear process.

- Recirculation and combination: After emulsification, the product can be pumped back into the mixing tank to be refined with coarse additives. The product is then discharged directly via a bypass.

This system architecture combines the advantages of a process automat with the strengths of a mixer, offering unprecedented process control. Thanks to the controlled pump feed to the emulsifier, precise temperature control is guaranteed – under vacuum conditions, which is crucial for product quality. This allows even sensitive formulations to be implemented reliably and reproducibly.

Benefits at a glance:

- Combination of mixing and grinding technology in one system

- Modular design for maximum adaptability to individual process requirements

- High-vacuum process control that improves product quality and shelf life

- Flexible further processing depending on requirements

- Efficient emulsification and homogenisation, even for complex products

- Precise control of temperature, mixing intensity and product flow

Complementary aspects of the KS mixer portfolio

The KS Mixing Centre is part of a comprehensive portfolio from KARL SCHNELL, which includes mixing systems in a wide range of sizes and configurations – from 30 to over 7,000 liters. Thanks to intelligent PLC control, separate motor control, vacuum intake for powder components, and precise temperature control, all production requirements can be reliably met. Its reproducibility and integration into continuous production lines make the system an ideal solution for the highest demands on quality and efficiency.

Conclusion

The KS Mixing Centre 600 V offers a unique combination of flexibility, process reliability, and efficiency. It is ideal for producers who demand the highest quality while simultaneously producing complex products economally – a true centre of innovative food processing.

Smart up your production – visit us in Hall 8.0 G96

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage www.karlschnell.de