International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

KS Diaphragm Koex - The solution for filled products!

KS Diaphragm Koex - The solution for filled products!

Description

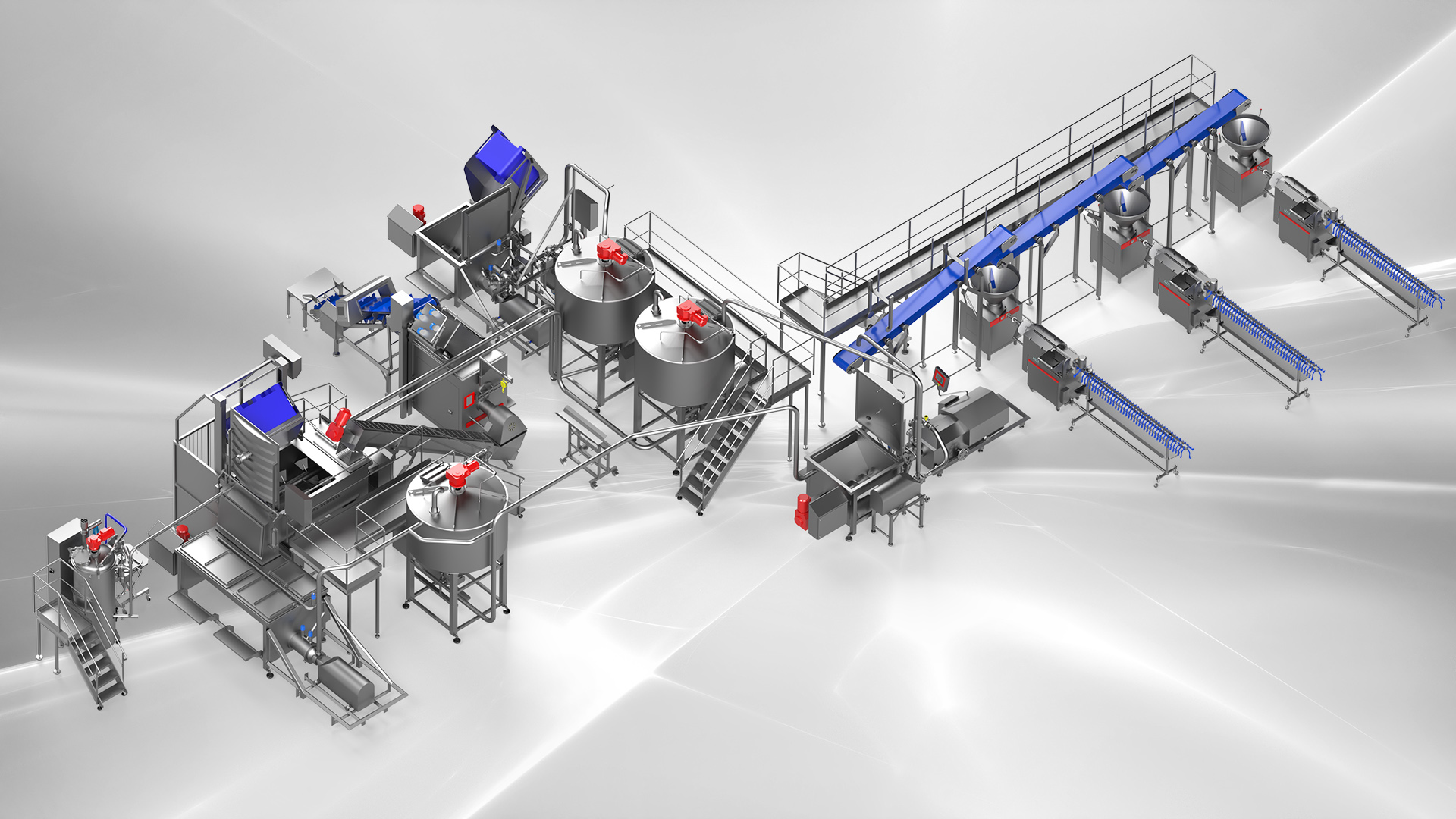

The KS Diaphragm Koex is a multifunctional portioning device in the food sector for processing all pasty and dimensionally stable products with internal filling.

Equipped with a modern drive concept based on a highly dynamic servo motor, a wide variety of food products can be portioned. And this in many sizes and individually configurable ratios of outer shell and filling.

The range of applications is enormous:

- From mini meat or cheese balls to large potato dough and bread dumplings

- Sweets in many shapes and types

- Moreover long products such as filled croquettes or cevapcici, and many more…

The type of filling as well as its consistency can vary - from low viscous sauces to highly viscous emulsions with chunky fillings - everything is possible.

The integrated filling flow divider ensures exact weight accuracy per lane and product. This enables the best possible efficiency in the use of raw materials with consistently high product quality.

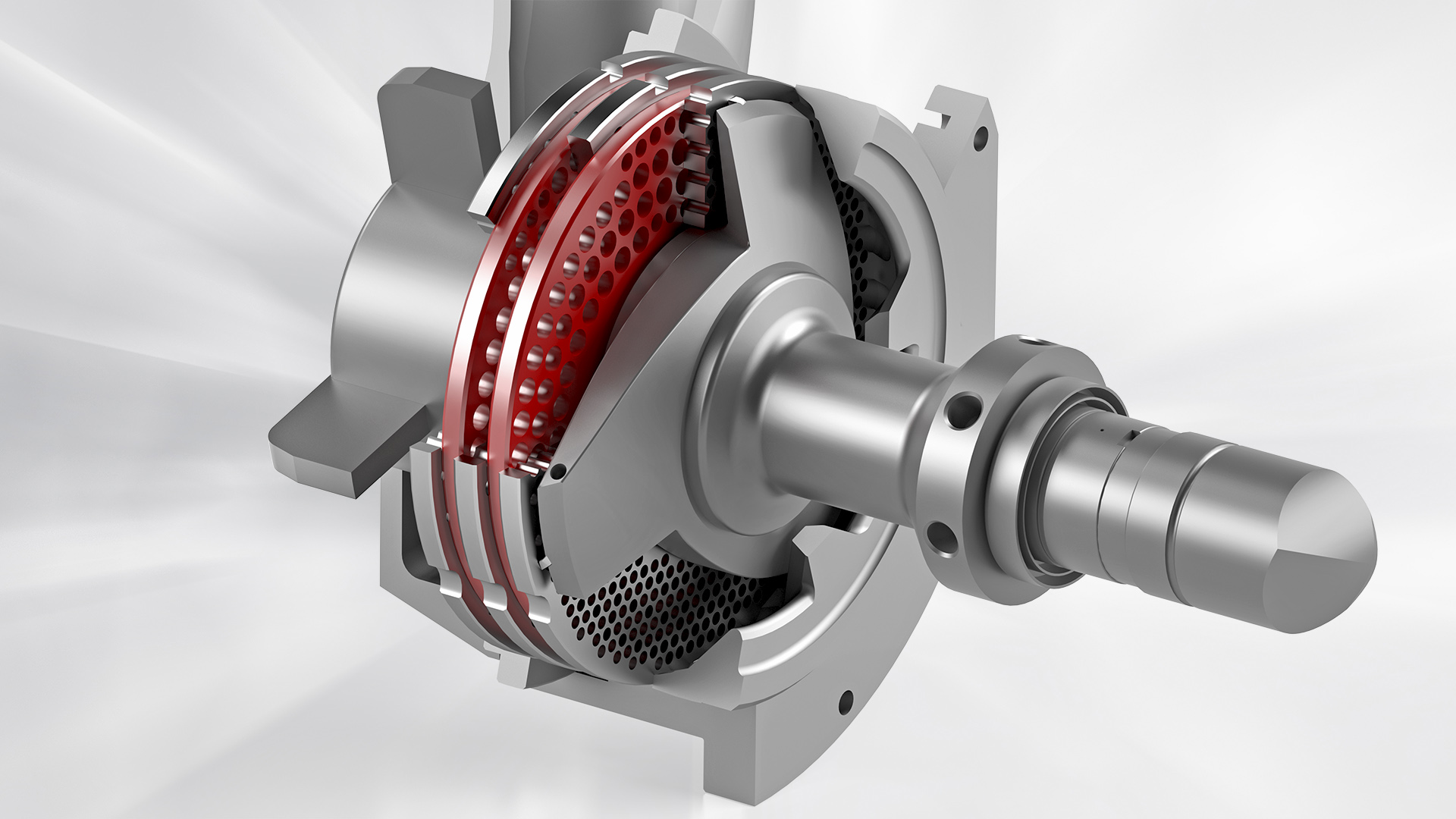

We offer two systems tailored to the customer's area of application:

- Control piston system - for use in continuously operating, high-capacity production lines

- Vane cell system - for flexibility in the downstream production process

Product injection - so-called coextrusion - thus allows a wide range of design possibilities, not only in terms of the specification and consistency of the two starting materials, but also their filling ratio to each other.

There are several options for dispensing the product:

- Dispensing onto a belt conveyor, for example, for further processing in a breading line or laminating system or for transfer to subsequent conveyors

- Direct dispensing into a water bath or oil bath system

- Dispensing onto a rolling belt for defined ball shaping for a variety of dumpling products.

Centrally controlled via KS Vacuum Fillers of the P-Series, the filling machines, portioning device and output conveyor form a single unit. In addition, the electromotive height adjustment of the complete diaphragm module offers easy and convenient positioning via the downstream production line.

The central servo concept for all drives ensures precise conveying and portioning with gram accuracy. All functions can be visualized and easily operated on the clearly arranged, swiveling operator terminal.

The specification and size of the product to be manufactured can be modified with just a few quick-change parts. This guarantees easy cleanability and best hygiene.

The modular design and the flexible combination options of the individual modules ensure efficient, ergonomic work with optimum production capacity utilisation.

Visit us live at IFFA in Frankfurt Hall 8.0 G96 from May 03-08 and learn more about how we can support you with your product ideas.