International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

KS Process Automats - Modern processing for smart product ideas

KS Process Automats - Modern processing for smart product ideas

Description

Innovation as a success factor

The development and introduction of innovative recipes and products is becoming increasingly important for producers of meat products, processed cheese applications and vegan alternatives. In order to exploit the full potential offered by the success factor of innovation, a modern, flexible machine park is required, together with a high level of technological know-how. This is the basis for a real competitive advantage and a successful product launch.

Reproducible, consistent quality is essential for producing this type of high-quality food. Furthermore, gentle processing and precise ingredient dosing are required in this sensitive area to achieve the best possible flavor in the final product.

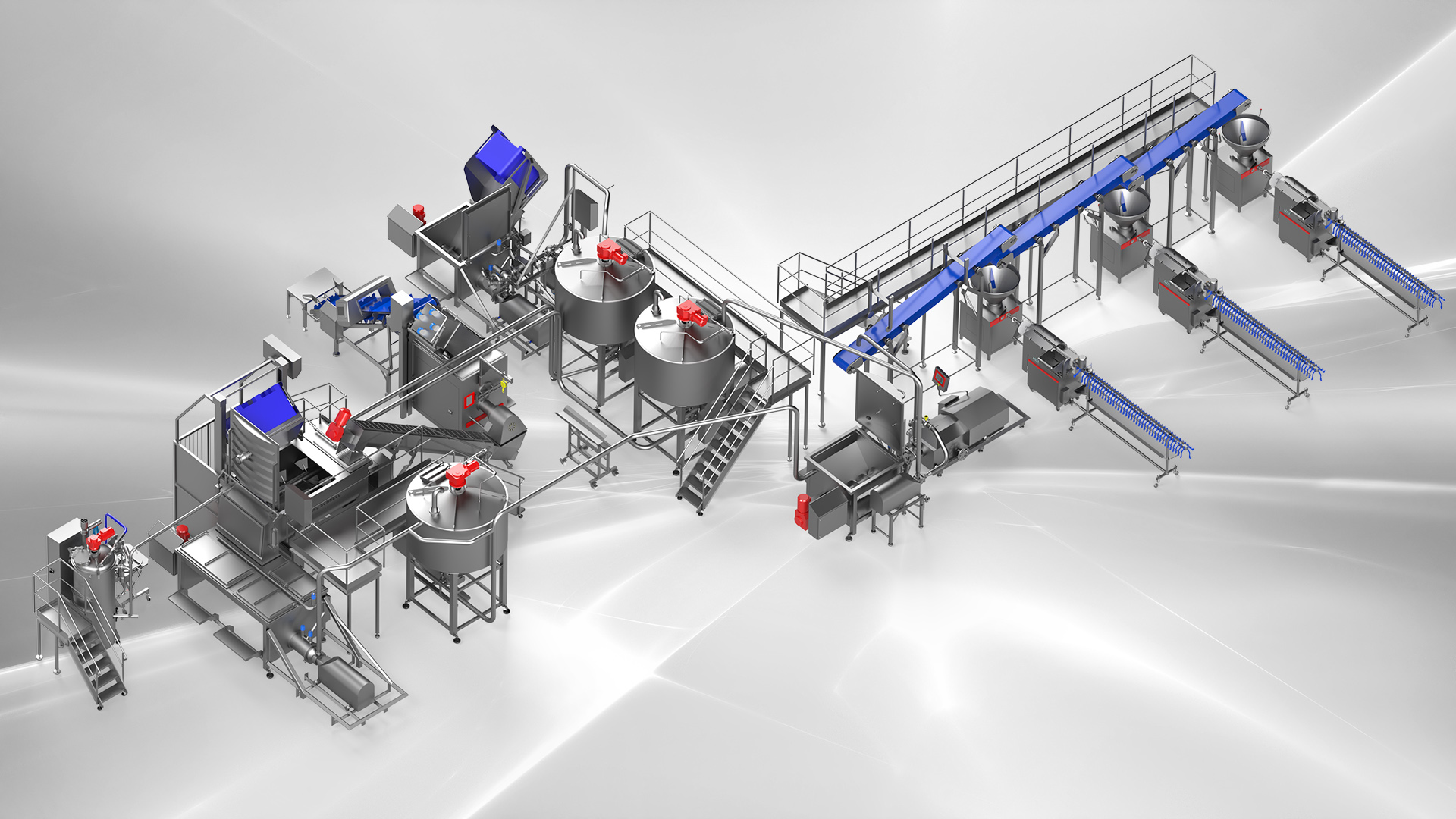

All-In-One Solution Process Automat

KS Process Automats offer maximum process reliability and efficient production flow - with significantly reduced batch times and low energy requirements.

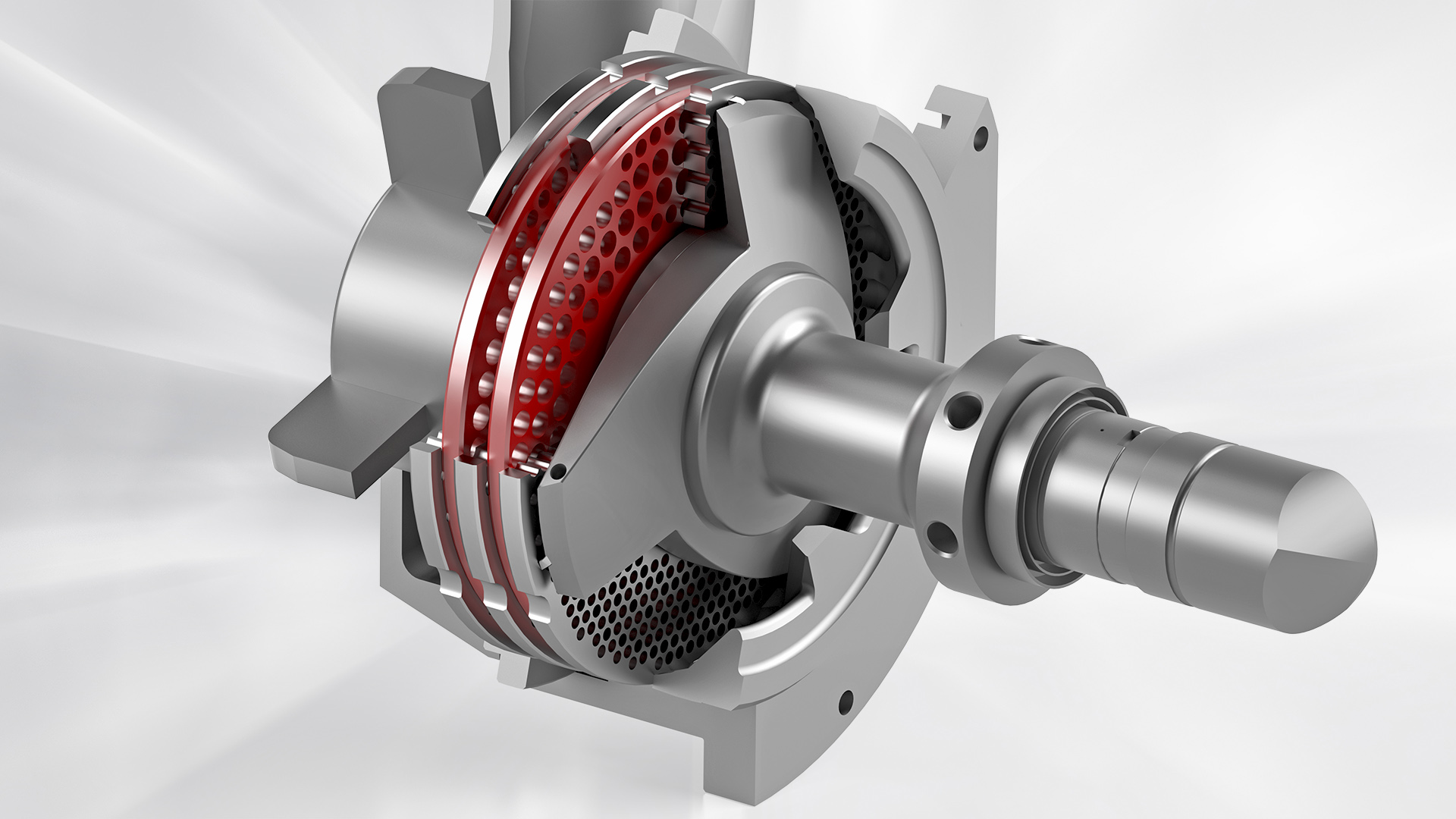

State-of-the-art ergonomic agitator tools mix and homogenize the individual ingredients of the formulation sustainably - without lump formation in the shortest possible time. The desired degree of emulsification can be freely adjusted. When processing fine emulsions, the use of the integrated emulsifier is indispensable and particularly effective.

In order to cope with the large number of different applications, the product temperature can be set with direct or indirect temperature control. The use of the vacuum system also guarantees permanent evacuation of the product during processing.

In addition to the automatic metering of additives from different silos and containers, complete integration of the machine control into an existing higher-level plant control system is also possible. This ensures that the product to be produced is delivered to the desired location in the desired quantity at all times. A wide variety of recipes can be stored in order to react flexibly to different products or product changes. The high degree of automation ensures precise, reproducible food production.

Intermediate cleaning of the machine, even during ongoing production, is performed by the CIP (cleaning in place) connection. The result of this self-contained system is the highest standard of hygiene without contamination or cross-contamination.

The automation in processing ensures standardisation. This guarantees the production of a wide range of permanently high-grade products in constant quality. In addition, it enables producers to react always with flexibility to the market and to position themselves optimally for the future.

Smart up your production – visit us in Hall 8.0 G96

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage

www.karlschnell.de.