International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Innovative hygiene solution for the highest demands: KS DSE-Series Emulsifiers

Description

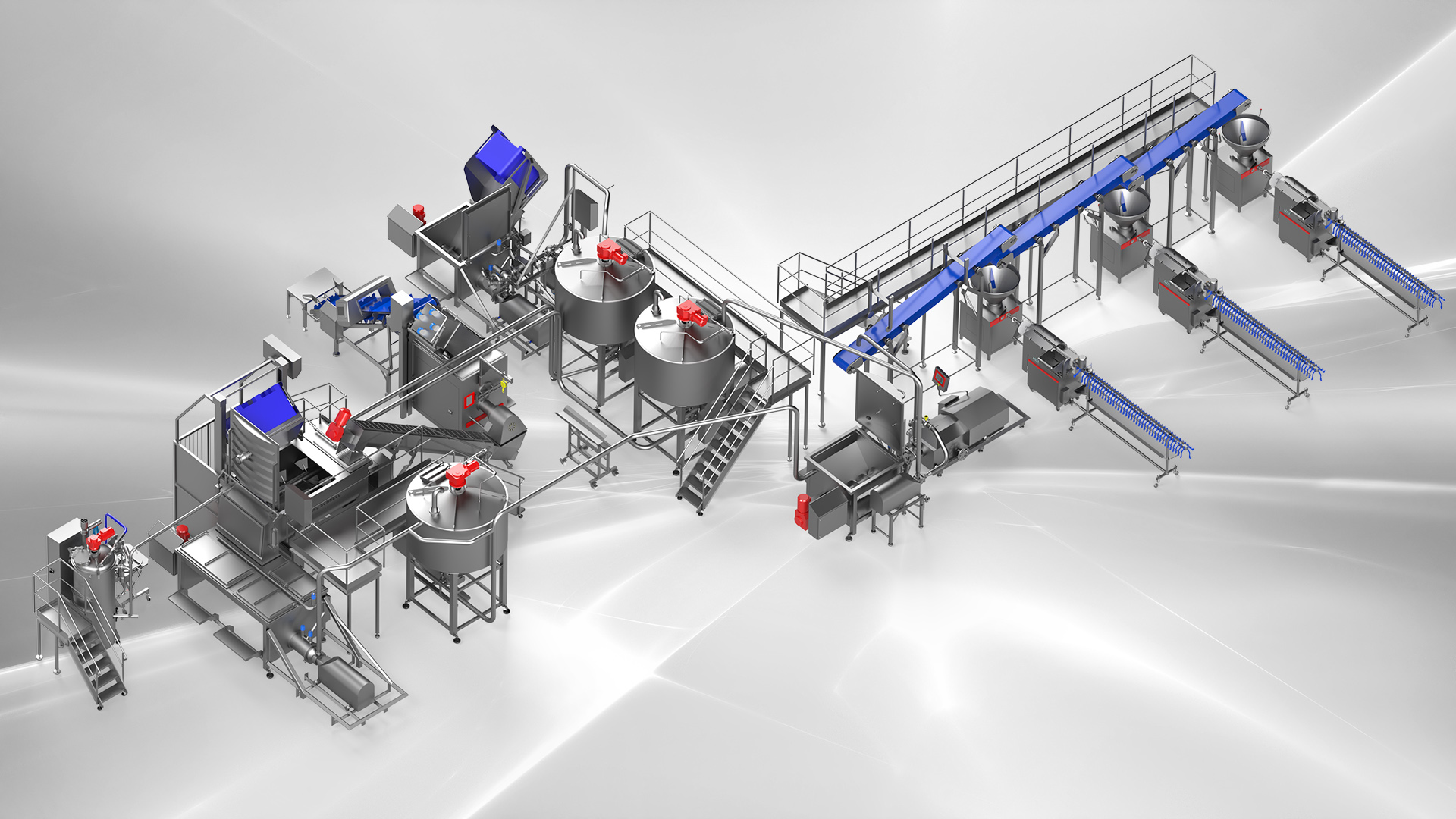

As a holistic solution provider, KARL SCHNELL is setting standards in terms of hygiene, efficiency and precision in the ultra-fine comminution of food with the new DSE-Series. The machines combine state-of-the-art technology with an uncompromising hygienic design, thus offering clear added value for demanding production environments.

Hygienic design according to the latest standards

The DSE-Series consistently meets the latest hygiene guidelines of the food industry. The modular motor unit is made of stainless steel and certified to protection class IP69 – ideal for use in wet rooms. The hygienic water cooling and energy-efficient, low-noise continuous operation guarantee maximum operational reliability.

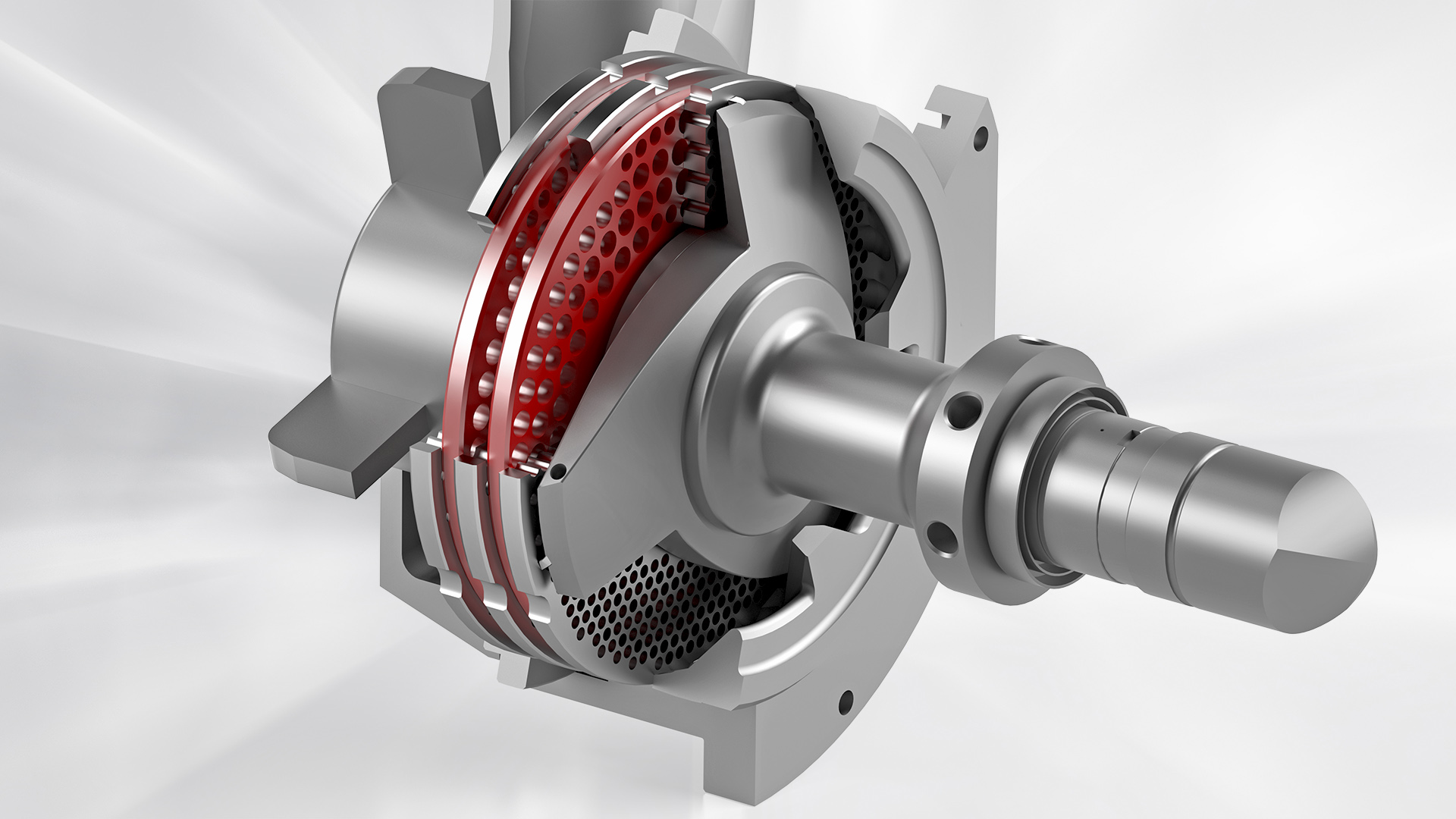

Powerful drive

With a maximum power of 150 kW and a variable speed range from 50 to 4500 rpm with constant torque, the universal drive unit offers maximum flexibility for a wide variety of applications. The axially adjustable motor shaft enables precise and loss-free adjustment of the cutting set during operation – for optimal knife positioning and minimal wear.

Versatile emulsifying unit

Benefit from the world's largest range of cutting systems and the unique ability to combine different cutting principles in one machine. This enables the production of homogeneous, ultra-fine products in a single operation – with the highest performance and maximum process reliability.

Hygienic Cutting System HCS

For particularly hygienically sensitive applications, KARL SCHNELL offers the world's first CIP-cleanable multistage cutting system HCS. The system sets new standards in the area of product safety, particularly with regard to the prevention of bacterial contamination and cross-contamination.

The HCS was designed for the gentle processing of low to medium viscosity, non-abrasive and short-fibre products. Typical applications include the production of delicatessen, baby food, ice cream, cream cheese and processed cheese.

The complete unit consists of a modular cassette housing optimised for CIP cleaning with an integrated bladeless special cutting set and a high-performance sealing system.

Cleaning takes place in a closed state, eliminating the need for blade changes and cutting set disassembly and ensuring continuous operation.

Precise regulation with KS Smart Control

The intelligent control system continuously monitors temperature and system status and enables definable shear positions as well as temperature-dependent automatic expansion correction. Different user levels are managed via personalized RFID login. Control is carried out directly on the machine via PLC and can be seamlessly integrated into existing systems.

Optional product feed

The optionally available KS Feed Hopper with integrated screw ensures precise temperature control – even with highly viscous materials – and further increases production speed.

Available in two versions: FD and FL – optimally adapted to specific requirements.

KS DSE-Series Emulsifiers – for maximum hygiene, top product quality, and efficient processes in food production.

Smart up your production – visit us in Hall 8.0 G96

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage

www.karlschnell.de.

Address

KARL SCHNELL GmbH & Co. KG

Mühlstr. 30

73650 Winterbach

Germany

Telephone+49 7181 9620

Fax+49 7181 962100

Discover more from us