International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Overall Quality Management and Control System QUICCA

Overall Quality Management and Control System QUICCA

Description

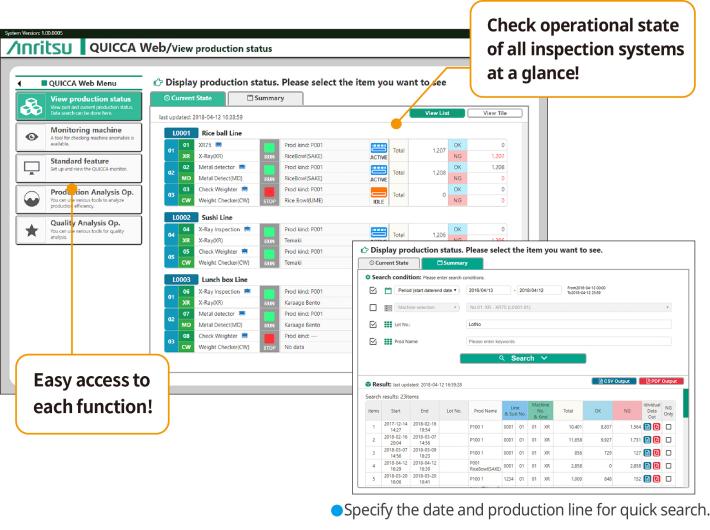

The production line in the palm of your hand. All your production data—anywhere, anytime

With QUICCA, diverse information including inspection data and operational history of all inspection systems are stored in one centralized location. QUICCA is the fully automated quality control and quality management software, ensuring product quality and productivity.

Displays historical and current production status

High level production line overview showing: Conveyor on/off, production counts, and reject counts.

Production information can be viewed simultaneously from multiple locations.

Displays real-time details for each machine

With QUICCA Monitor, individual users can customize the display with information they require, enabling quick data analysis for fast, accurate decisions.

Access QUICCA from the plant floor, offices, and meeting rooms

Production information and an error message are automatically sent to the user’s mobile phone for instant notification.

Complete Product Traceability

The Inspection data and operational history of all inspection systems are automatically recorded, in chronological order, in one centralized location. When receiving complaints from consumers or retailers, the desired inspection data can be extracted via the data output wizard to confirm there were no process problems.

- Lot number and time/date traceability

- Quickly search inspection data by scanning the product's bar or 2D codes

- View the complete product history including its inspection by ALL Anritsu X-ray, Checkweighing, Metal detection and video recording system on the line

HACCP Compliance

Daily operation checks become more reliable.

CCP compliance requires verifying the operation of the inspection equipment on a regular basis. QUICCA automatically records these operation checks and the associated product name, time/date and the operator ID who performed the check. The automatic data collection eliminates possible recording omissions or recording errors.

- Create CCP monitoring report

- Provide product inspection report

- Minimize the potential for human error

- Record operator ID to each event

- Quickly search date, shipment number or lot number