International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

XR75 Large model X-ray Inspection System

XR75 Large model X-ray Inspection System

Description

Best suitable for large cartons, cases and bags.

Advanced X-ray Technology and Simple Operation Contribute to the Enhancement of Product Quality

In addition to detecting metal contaminants, X-ray systems are capable of identifying shape defects, missing and broken products. The Anritsu XR75 X-ray Inspection System for large products is suitable for the inspection of products in large cartons, cases, and bags. The XR75 Inspection System for large products offers consistent and reliable inspection results on your production line with its outstanding detection sensitivity, ease of operation, and enhanced durability.

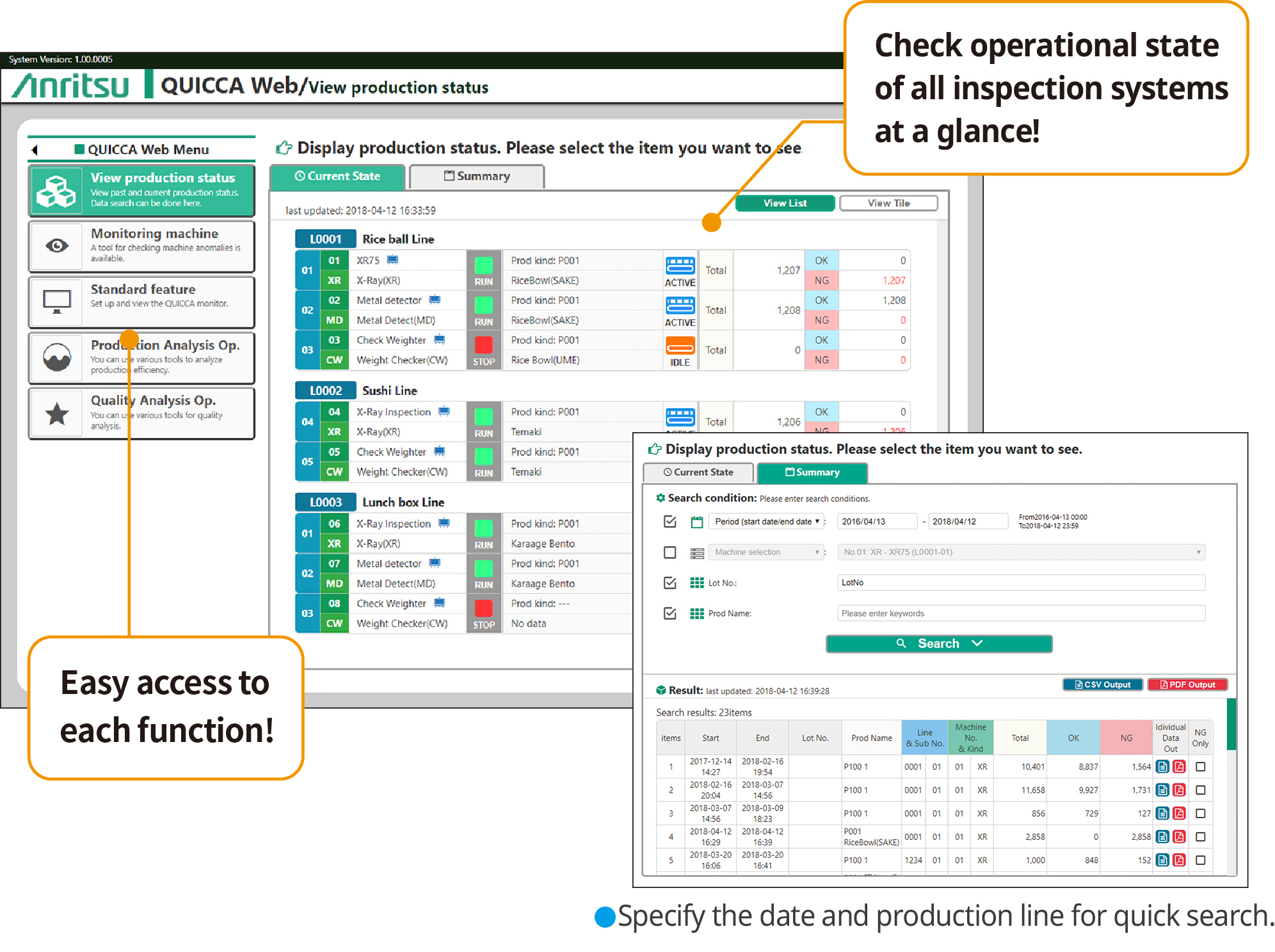

Intuitive, Time Saving Software

XR75 software helps operators work more efficiently, displaying reject images on the screen to easily identify contaminants.

Improvements from previous models

- Conveyance capacity

The XR75 for large products is equipped with a high power motor, which enables the system to convey a dry product up to 50 kg and a wet product up to 40 kg. - High rigidity of moving parts

The rigidity of moving parts such as a conveyor cover and a motor are enhanced by performing continuous testing using the intensity analysis. - More options available

Extension conveyor and extension cover can be chosen according to the product length as an option.

KXS7554AWHSE

X-ray output: Tube voltage 30 to 80 kV, tube current 0.4 to 10.0 mA, output 350 W

Safety: X-ray leakage maximum 1.0 μ Sv/h or less, prevention of x-ray leakage by safety devices

Display: 15-inch color TFT LCD

Operation method: Touch panel (with touch buzzer)

Detection area: Maximum width 590 mm, maximum height 250 mm (Pass height of 350 mm is available as an option.)

Preset Memory: 200

Belt Speed / Maximum product weight:

Dry environment |

10 to 30 m/min maximum 50 kg

31 to 40 m/min maximum 40 kg

20 to 70 m/min maximum 20 kg (optional)

Wet environment where water or oil is scattered on the conveyor |

10 to 30 m/min maximum 40 kg

31 to 35 m/min maximum 30 kg

36 to 40 m/min maximum 20 kg

20 to 60 m/min maximum 20 kg (optional)

61 to 70 m/min maximum 10 kg (optional)

Power requirements: 100 Vac to 120 Vac ±10% or 200 Vac to 240 Vac ±10% (However, switch the tap of a transformer), single phase, 50/60 Hz, 1.2 kVA (1.9 kVA with optional air conditioner), rush current 70 A (typ.) (40 ms or less)

Mass: 480 kg (525 kg with optional air conditioner)

- Environmental conditions: Temperature: 0°C to 35°C (0°C to 40°C with optional air conditioner), relative humidity: 30% to 85%, non-condensing

Protection class: Conveyor: IP66 Other parts: IP40

Exterior: Stainless steel (SUS304)