International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

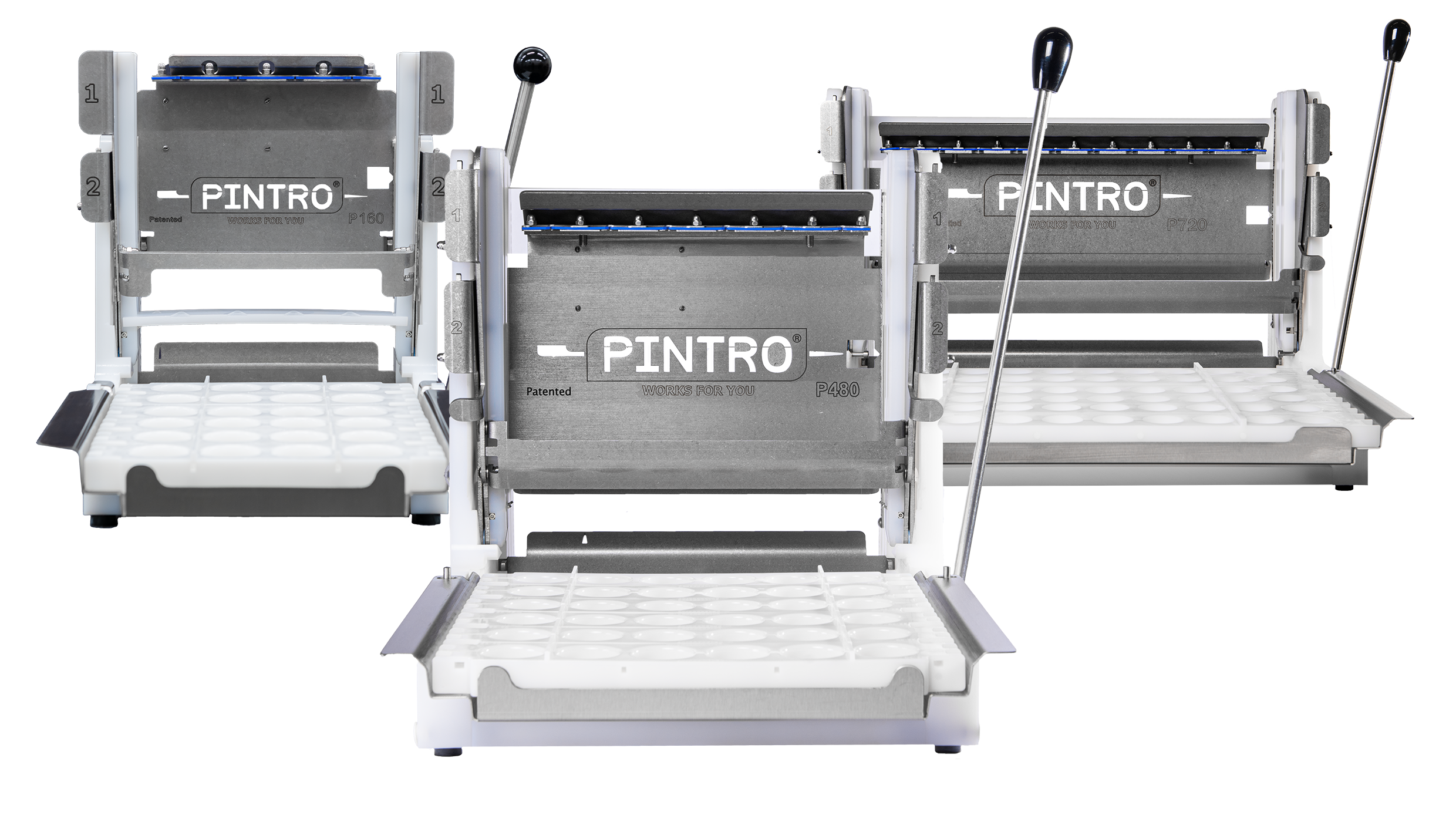

PINTRO P1000 | P3000 - semi automatic skewering machines

PINTRO P1000 | P3000 - semi automatic skewering machines

Description

PINTRO semi-automatic skewer machines for satays and brochettes enable large food processing companies to efficiently prepare large volumes of artisanal satays, brochettes and kebabs and other skewered meat products.

P1000

PINTRO® P1000 is a semi-automatic skewer machine that assembles skewers as if they were pierced by hand. This machine is meant for large-scale food producers such as suppliers to the hospitality industry or other businesses that produce brochettes, satays and skewers in large quantities. The end product appears artisanal yet uniform and ensures consistent quality.

- 1000 skewers / kabobs per hour

- Maintains a traditional-style look and feel for the product

- Ergonomic and hygienic operation

- All skewers have an even look

- Compact machine: 100 x 70 cm

- Mobility: using a pallet jack

One operator is needed to control the machine, while 2 to 4 workers are needed to place the ingredients on the product holders. More or fewer workers may be needed, depending on the number of ingredients per skewer. The PINTRO P1000 is simple to use for everyone.

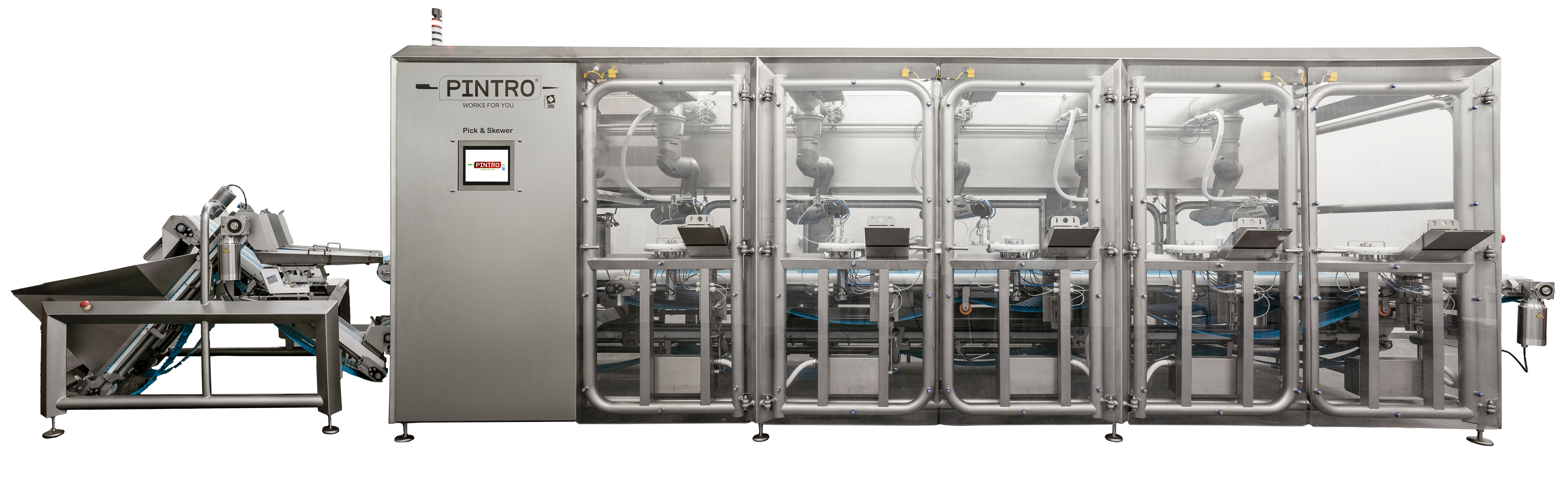

P3000

The PINTRO® P3000 is the newest addition among the semi-automatic skewer machines. It is ideal for industrial major seasonal production quantities of up to 24,000 skewers per shift. The central theme is the traditional appearance of the skewer; constant quality, ergonomics and productivity.

- 3000 skewers / kabobs per hour

- Maintains a traditional-style look and feel of the product

- Ergonomic and hygienic operation

- All skewers have an even look

In developing this machine, we took account of the highest possible capacity, an ergonomic, pleasant and safe working method for the operators, simple conversion for making other skewers and, of course, the traditional final result of the skewer.

Two master stations are occupied by on the one hand the machine’s operator and on the other hand a team that fills the moulds with ingredients.

One operator removes the formed skwers from the installation and performs a visual final inspection. A number of ‘fillers’ supply the moulds with the ingredients. The number of fillers depends on the quantity and diversity of the different components of the skewer. The installation has room for a maximum of ten fillers.

We have provided convenient filling towers so that the fillers only need to make as few movements as possible with plenty of autonomy.

The HMI display and its menu provide simple controls for e.g. making another type of skewer; it includes instructions and other relevant information such as the productivity.