International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

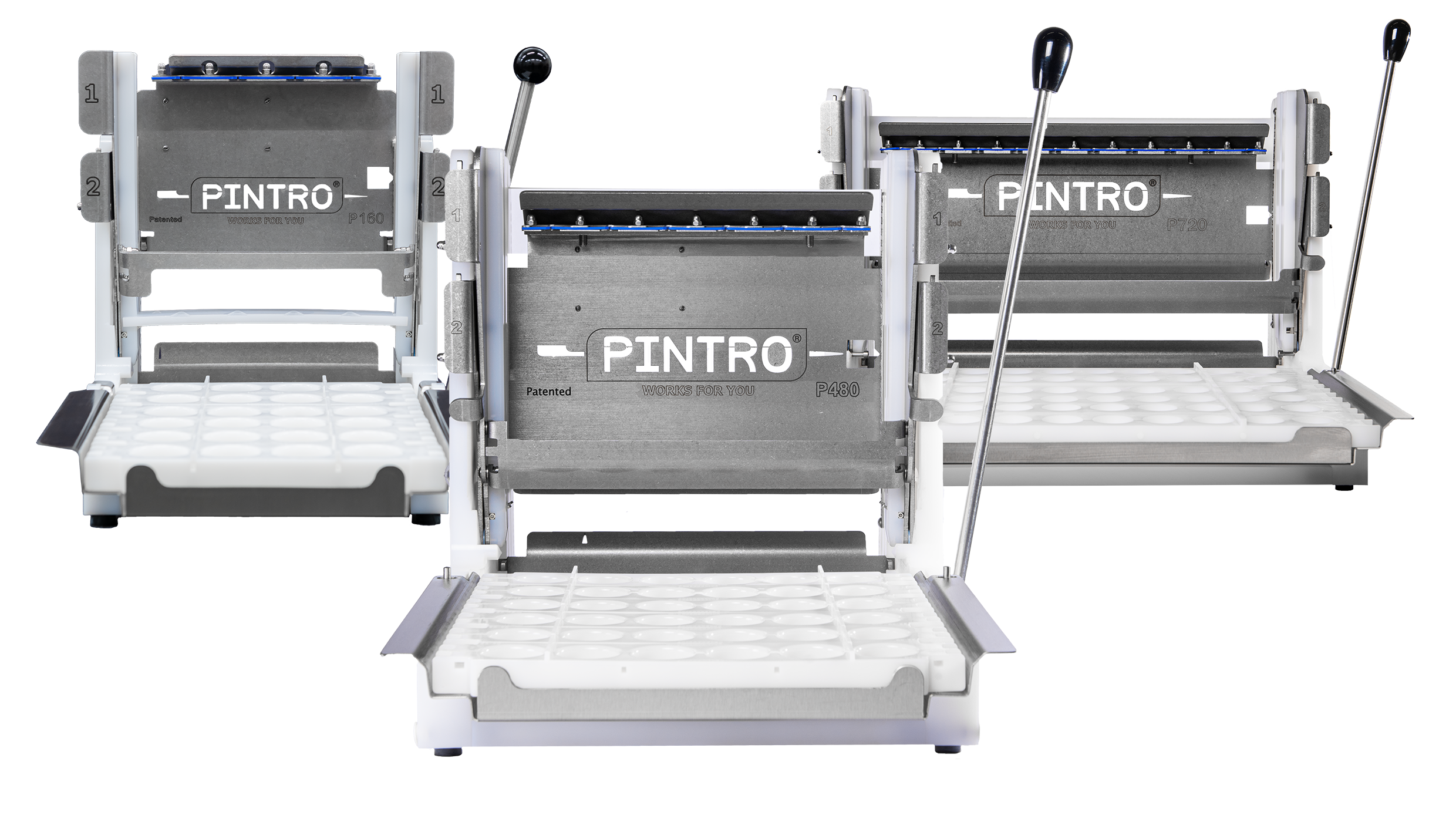

PINTRO Pick & Skewer - world's first fully automatic skewering machine

PINTRO Pick & Skewer - world's first fully automatic skewering machine

Description

Our PINTRO Pick & Skewer is the world’s first fully automatic skewer machine. The process of feeding the ingredients, the picking & placing on the skewering sticks and the evacuation of the finished products are fully automatic.

The sophisticated vision system permanently monitors the quality of the product. The location and orientation of the ingredients, as well as the position of the skewer tip are closely monitored during the pricking process.

- Minimum staff required

- High productivity

- Traditional-style product

- Steady output

- Multifunctional and flexible

- Hygienic

- Ingenious techniques – Easy operation

It only takes a simple touch on the HMI screen for the logistical operator to select a recipe. He also supplies the hoppers with ingredients and resupplies the skewer container with sticks. Touching the start button will launch the machine to fully automatically produce skewers / kabobs.

The ingredients are automatically fed into the machine. They are separated, then transported on a conveyor belt to be presented for picking by the robot. An additional logistical operator may sometimes be needed to separate certain ingredients.

Each robot has a pair of customized grippers that will pick up the ingredients and place them perfectly centred onto the skewer stick. The vision system detects the location and orientation of the ingredients and then calculates and transmits the best position for pricking. For meat chunks this may e.g. mean that we want the piece to be picked and placed lengthwise onto the stick. For vegetables we could define that the robot should only pick and place convex pieces. These settings can be predefined and programmed according to the client’s needs.

The automatic skewer stick selector presents one skewer at a time facing the robot. The tip of the stick is permanently being monitored to ensure central pricking at all times. The completed skewers are transported out of the installation via a conveyor belt to a central collection point.

2-5 robots

Depending on your requirements an installation may consist of between 2 and 5 robots. A single robot can process about 3.300 components per hour.

Evacuation of completed skewers / kabobs

Typically, the completed skewers will be transported out of the installation to a central collection point. Feel free to ask for possibilities to integrate this part into your current infrastructure or process.