International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

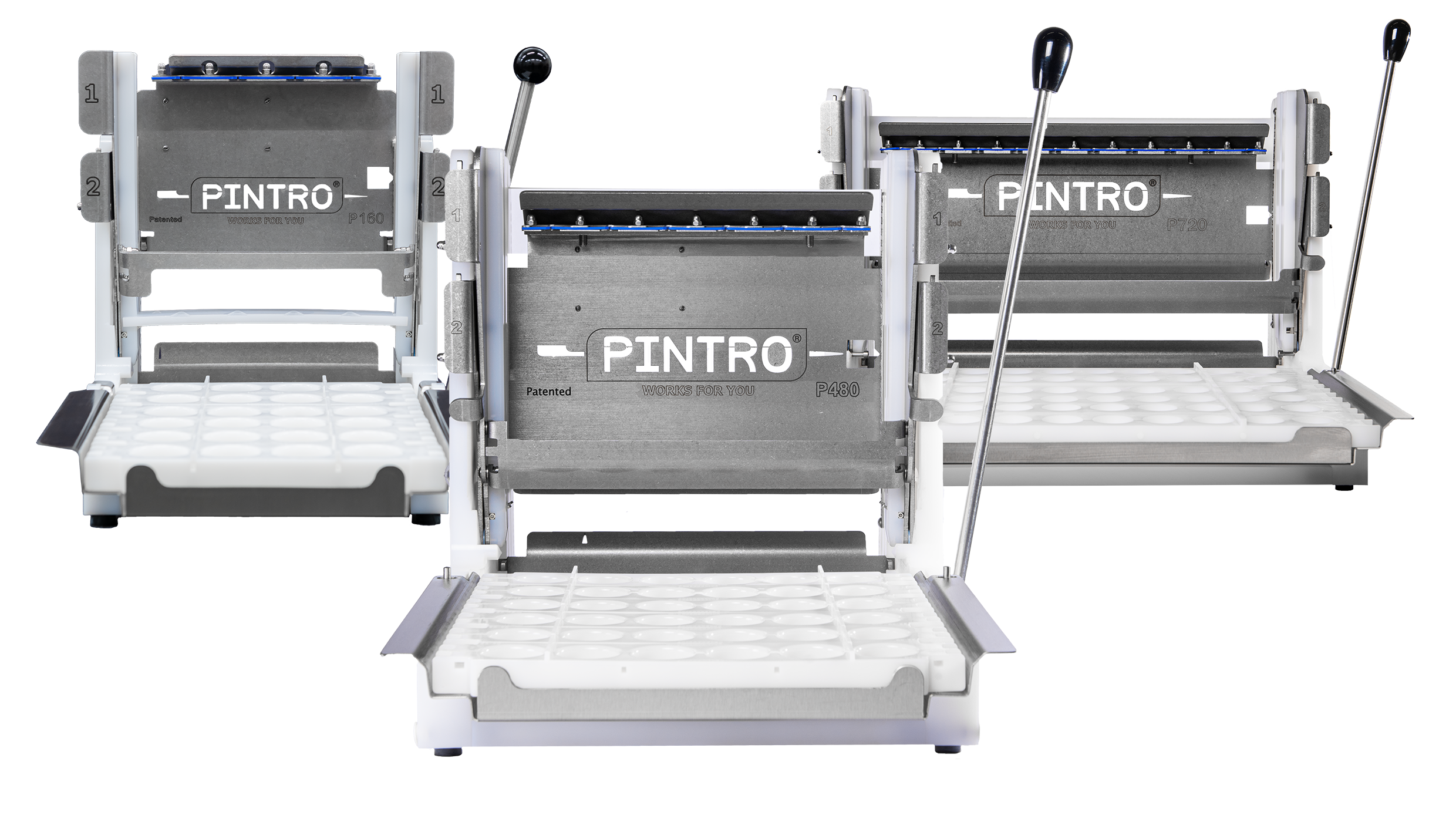

PINTRO MBF 50(-C) - Meatball formers

PINTRO MBF 50(-C) - Meatball formers

Description

The PINTRO Meatball Former is the ideal device for the production of large quantities of meatballs in different weights and sizes while maintaining a traditional look.

You can choose sizes from small soup balls to medium sized party or snack type meatballs. Exchanging calibres only takes a few minutes. In no time you are able to switch from a small size to a bigger one.

Various sizes

You can choose sizes from small soup balls to medium sized party or snack type meatballs.

Evenly round shapes

The unique forming system of the device produces even meatballs with identical sizes and weights.

Quick changes

Exchanging calibres only takes a few minutes. In no time you are able to switch from a small size to a bigger one.

For small and medium enterprises and for industrial environments

The ideal tool for every butcher, party service, caterer, ready-meal producer, but also for medium and large size production plants.

Connects to every type of sausage filler

The machine comes with an adapted flange so that it can easily be connected to virtually every sausage filler.

Easy cleaning

The entire machine can be disassembled for cleaning purposes. Most component are dishwasher proof.