International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

BRINE MIXERS

Description

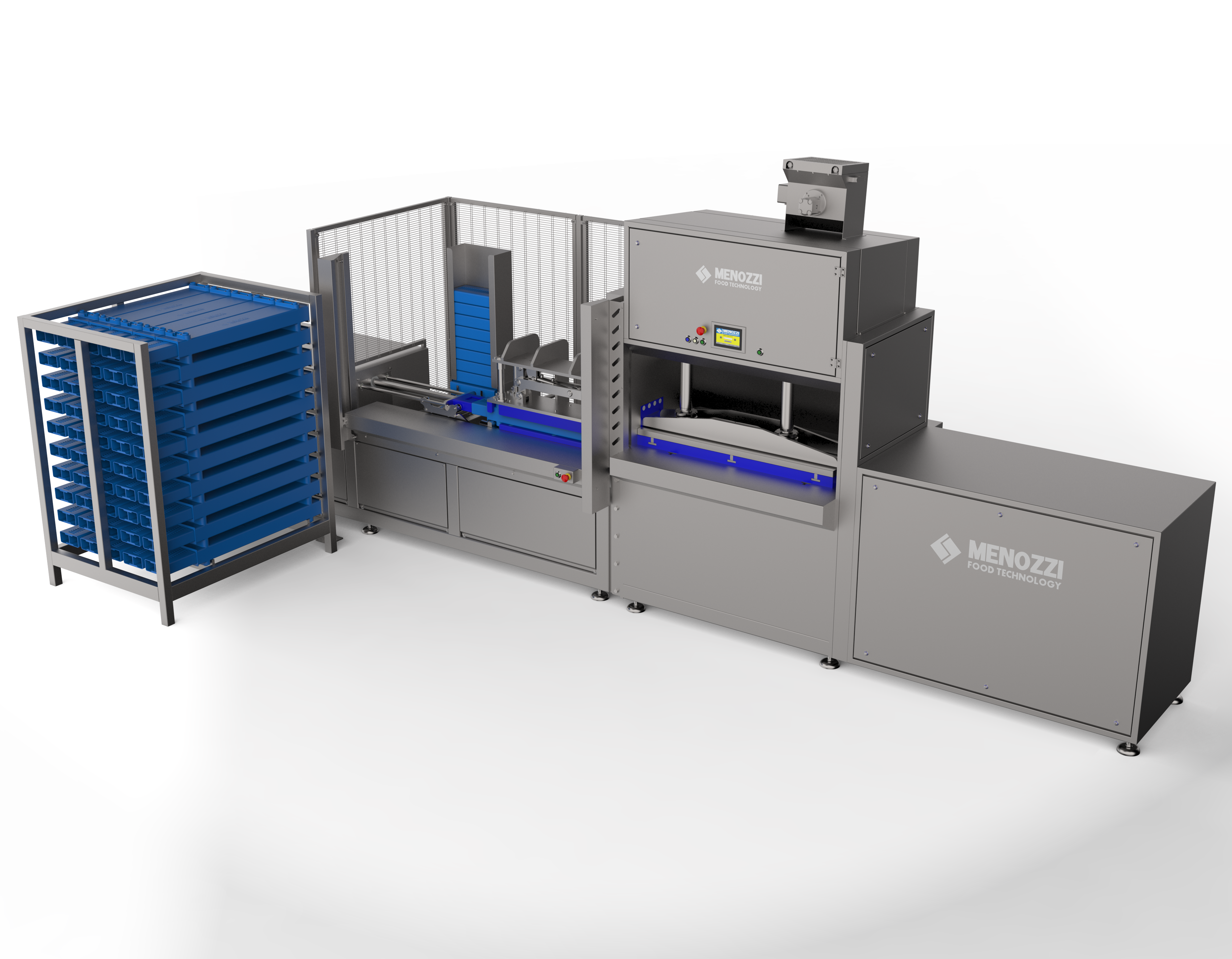

MM

low viscosity brines

The mixing system for brine MENOZZI MM 350-3000 dissolves in water salt, sugar, starches, oils, gums, spices etc. without foaming. All ingredients are easily loaded in the hopper thanks to the sack-chute and thanks to the large waist the hopper is provided with.By starting the pump the ingredients are efficiently mixed in a short time and form a perfectly homogeneous and emulsified brine. The prepared brines remain than suspended because of the action of the pump (regulated by a timer) that re-circulates the brine and, at the end, transfers it to the injector or to the storage tanks.

MM ATOM

high viscosity brines

Menozzi High Shear Mixers MM-ATOM 1000-3000 are employed to produce viscous emulsions , that is to dissolve in water ingredients such as: starches, proteins, pectines, karrageen and caseinesinates or for the preparation of saturated brines.The vertical centrifugal pump is seated directly under the hopper. The mixing chamber of the pump is provided with a grid that acts as a crushing mill and as a high speed mixer.This high shear pump pushes the products through the grid, that breaks any smallest part of each ingredient. so that also the most difficult ones are micronized and dissolved. Also the thickest brines become homogeneous and impalpable, without any lump.The brine is much more stable and It sediments very slowly. This brings a huge advantage in the injection phase and to the quality of the final product. Further to this, mixing time to prepare brine is remarkably shorter. The capacity of mixing and dissolving the ingredients of this machine is so high that it is used in confectionary, to prepare creams or viscous and dense thicky emulsions.

Each machine can be adapted to the different need of each customer and equipped with the following devices:

- Double jacketing for cooling by glycol + external insulation (MMR-G)

- Double jacketing for cooling by ammonia + external insulation (MMR-A) ASME certified

- Double jacketing for heating by hot water + external insulation

- Double jacketing with coil for indirect cooling + external insulation

- Thermal probe and temperature display

- Litre-counter at the inlet for loading the tank with water

- Maximum and minimum level sensor.

- Control panel box with double door and double seal.

- Automatic valves (electro pneumatic).

- Mechanical paddle agitator.

- AISI 316 stainless steel

Address

Menozzi Luigi & C. S.p.A.

Via Roma 24/A

42020 Albinea Reggio Emilia

Italy

Telephone+39 0522 35471

Fax+39 0522 599743