International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

AUTOMATIC PACKAGING

Description

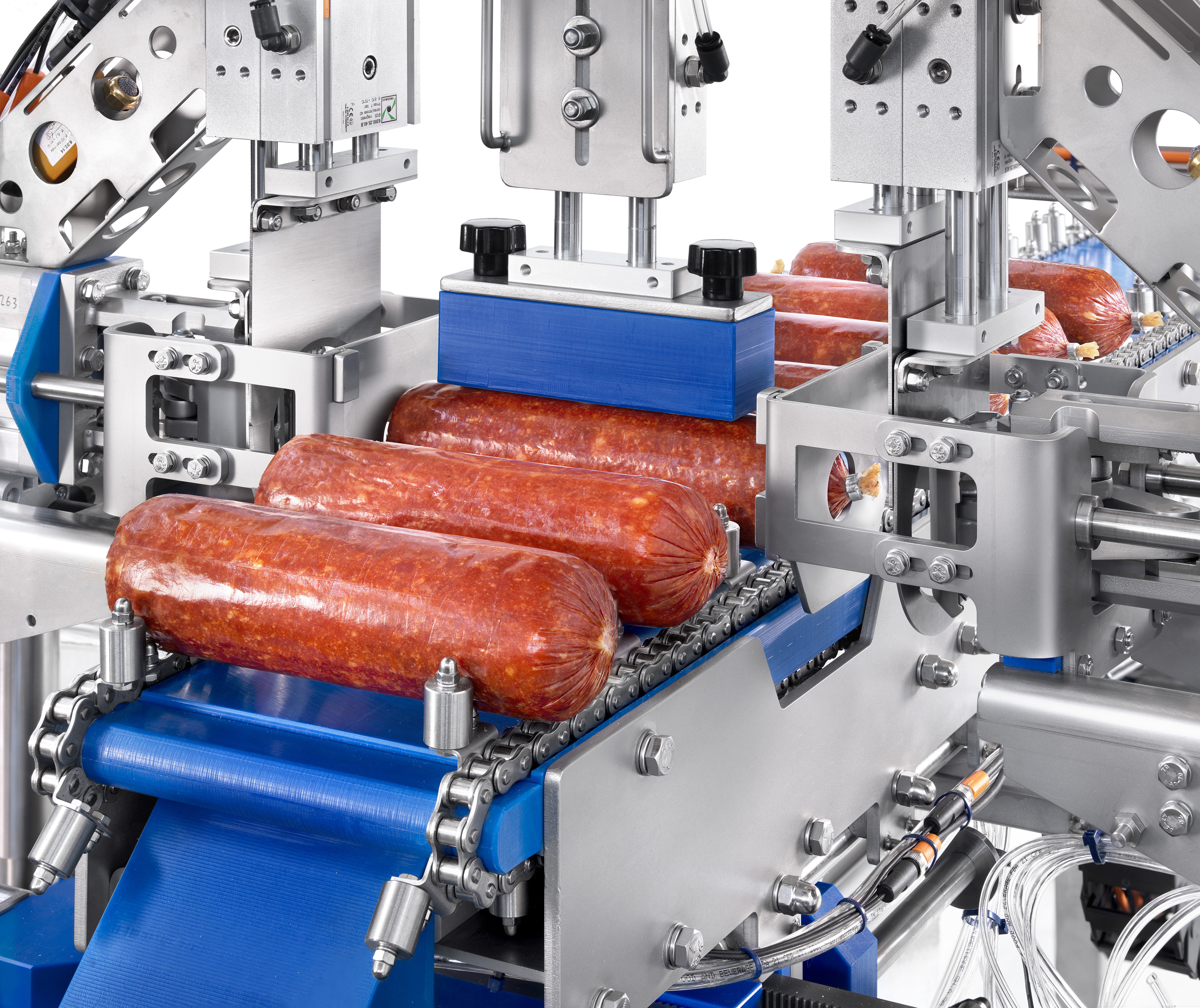

We produce different systems to package your products.

Our extremely compact CONFSV vacuum bagging and packaging lines can use either aluminum bags, shrink bags or taped bags. Easy adjustments ensure excellent qualitative and quantitative results and the different models can produce from 360 to 720 pieces/hour. They are used for cooked or cured products, whole or in portions, for cheese and for vegetarian or vegan products.The automatic bagging machine receives the products, appropriately oriented, on its loading conveyor belt. The gusseted bags or the sacks, are stacked in a special adjustable warehouse, orientable, or with a double drawer to allow loading without stopping production, for greater productivity. The packaging machine feeds our vacuum thermosealing tunnel, with sealing bars of 1.4 m, 1.8 m and 1.95 m, with side-by-side resistances conformed in such a way as to ensure maximum sealing pressure which, in this way, is less sensitive to micro-folds and the presence of traces of product.For bagging, a special device makes it possible to give to the mouth the shape required for the best and most reliable vacuum sealing, without the need for personnel. This device can be adjusted according to the size of the product.

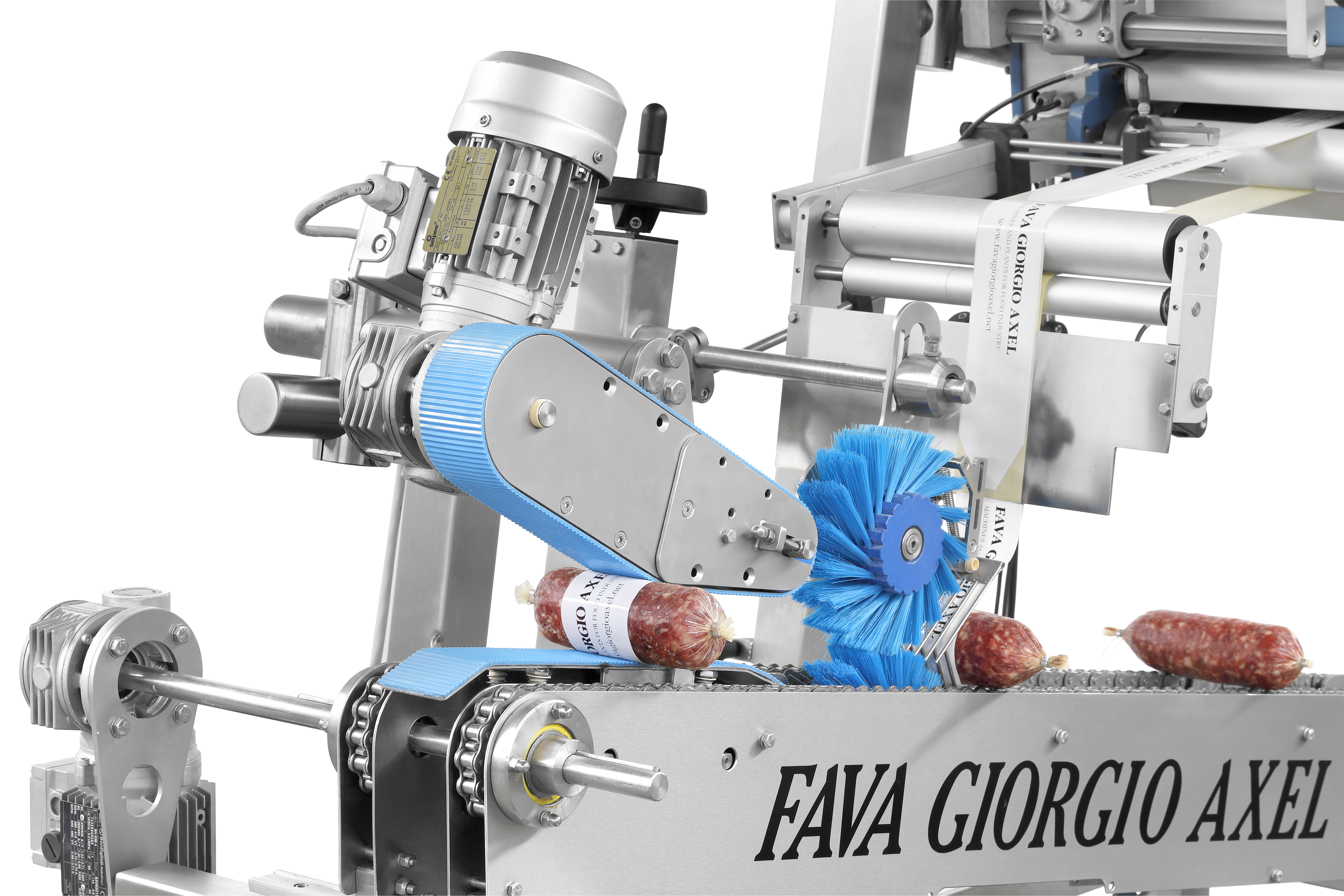

CONF AUTOMATIC PACKAGING

The packaging machine for taped bags can also handle cylindrical-shaped products; like the previous ones, it is equipped with an infeed conveyor belt, a pusher and a spreading device which, in cooperation with a blower, allows the bag to be opened, minimizing the size of the bag with respect to the product. Our packaging machines can also feed vacuum belt machines of other manufacturers.

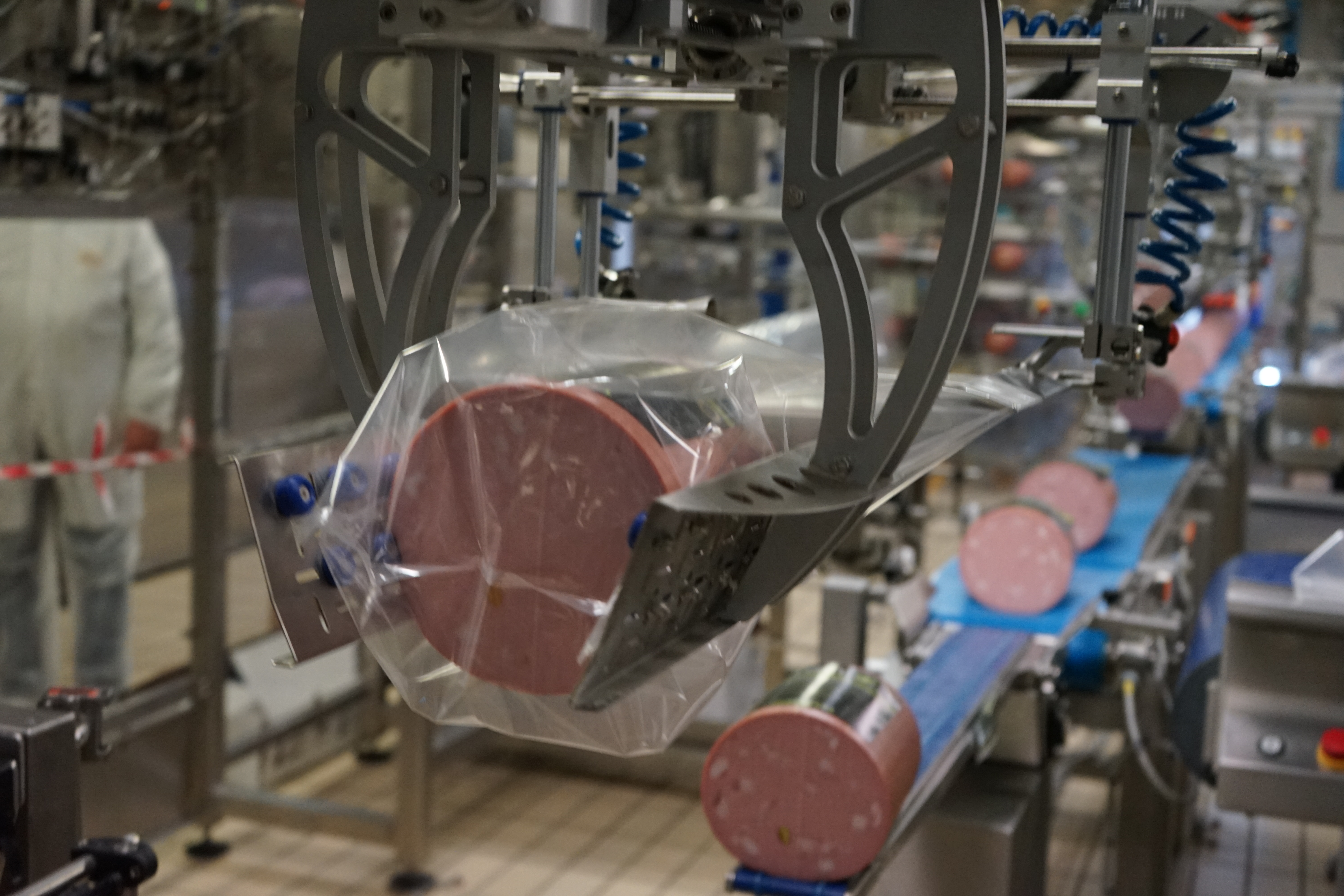

ROBOTIZED PACKAGING

We produce robotic systems for packaging in taped bags and automatic loading of the vacuum machine belt, suitable for circular and flat shaped products, be they mortadella or cheese or vegan and vegetarian products, with lengths up to 1.200 mm. The special design of the grippers makes it possible both to reduce the use of plastic material and to conform the mouth of the bags for better and more reliable vacuum sealing.

Address

Fava Giorgio Axel s.r.l.

Via A. Cerati 19 A

43126 Parma

Italy

Telephone+39 0521 293734

Fax+39 0521 293968