International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

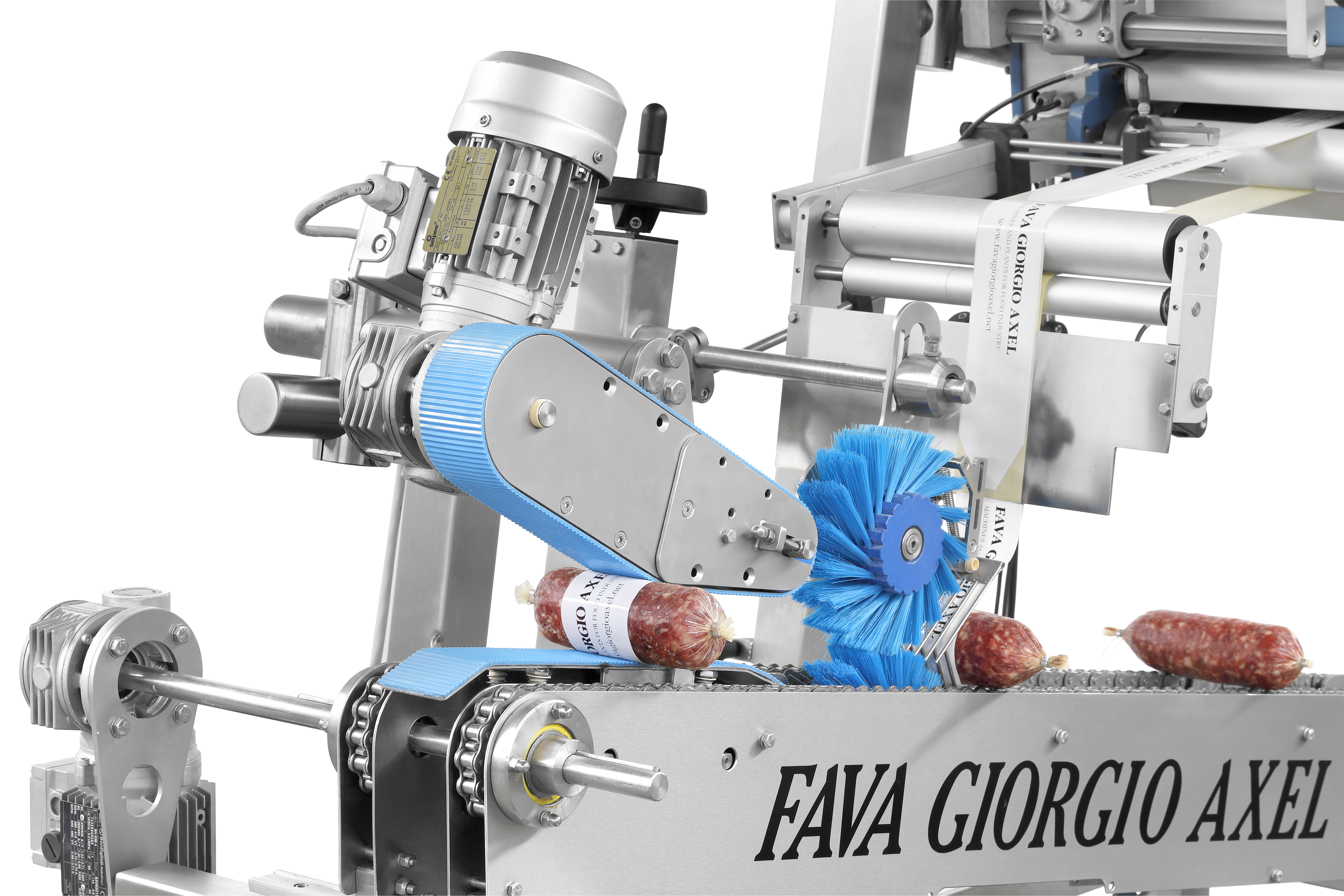

LOADING AND UNLOADING SYSTEM FOR SALAMI

Description

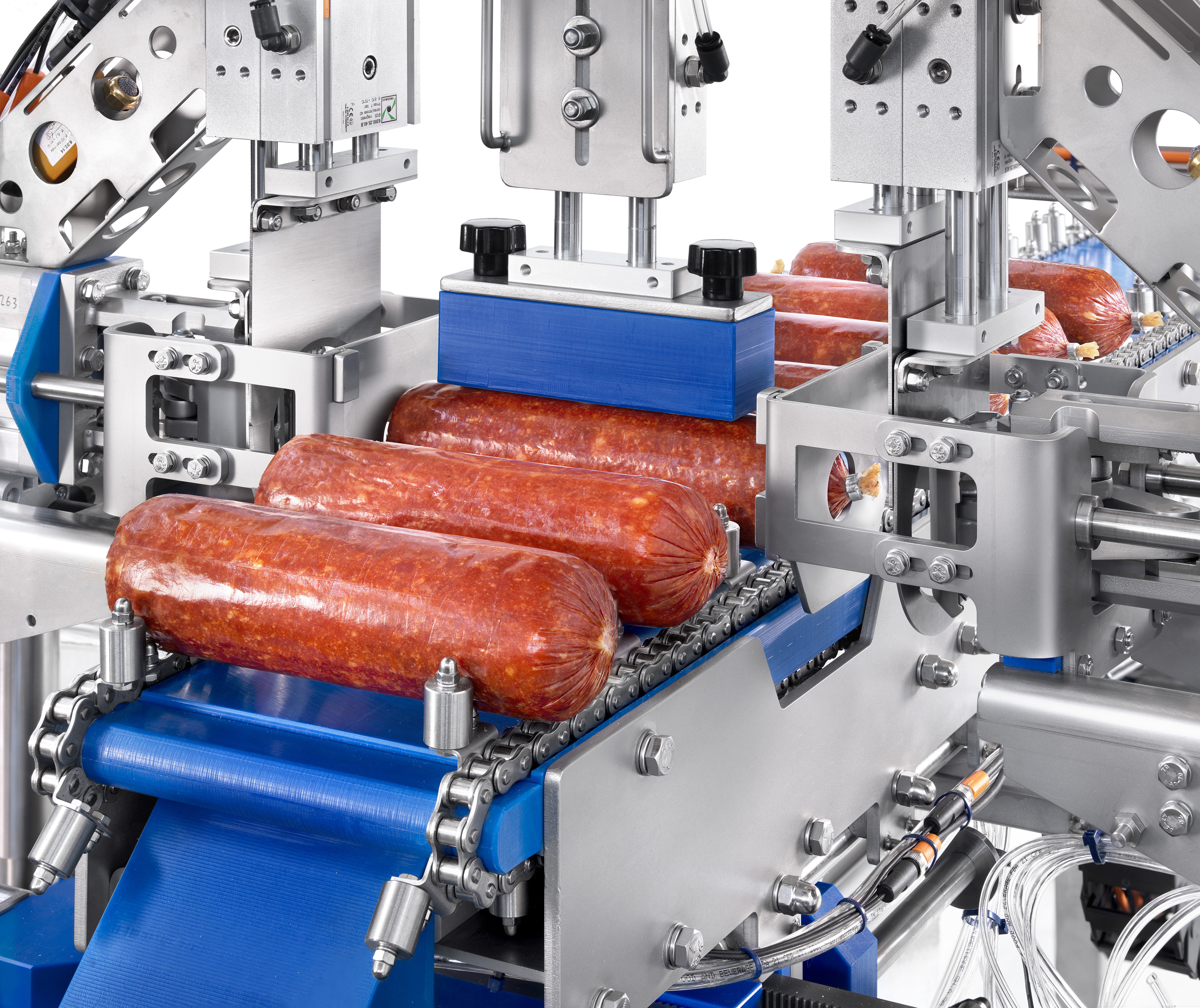

The TFRC system for loading and unloading hung deli meats, on trolleys, frames, trees or suspended conveyors, even of great height, can handle different products at the same time, coming from semi-automatic loaders, from automatic loaders, or taken from frames from production areas where manual loading is limited to the easiest level.

The same system is part of our system for the automatic hooking and unhooking of bellies for bacon.It is possible to pick up all the bars of an entire level; optimal acceleration management allows high speeds with very little oscillation of the products, with high throughput without products dropping.

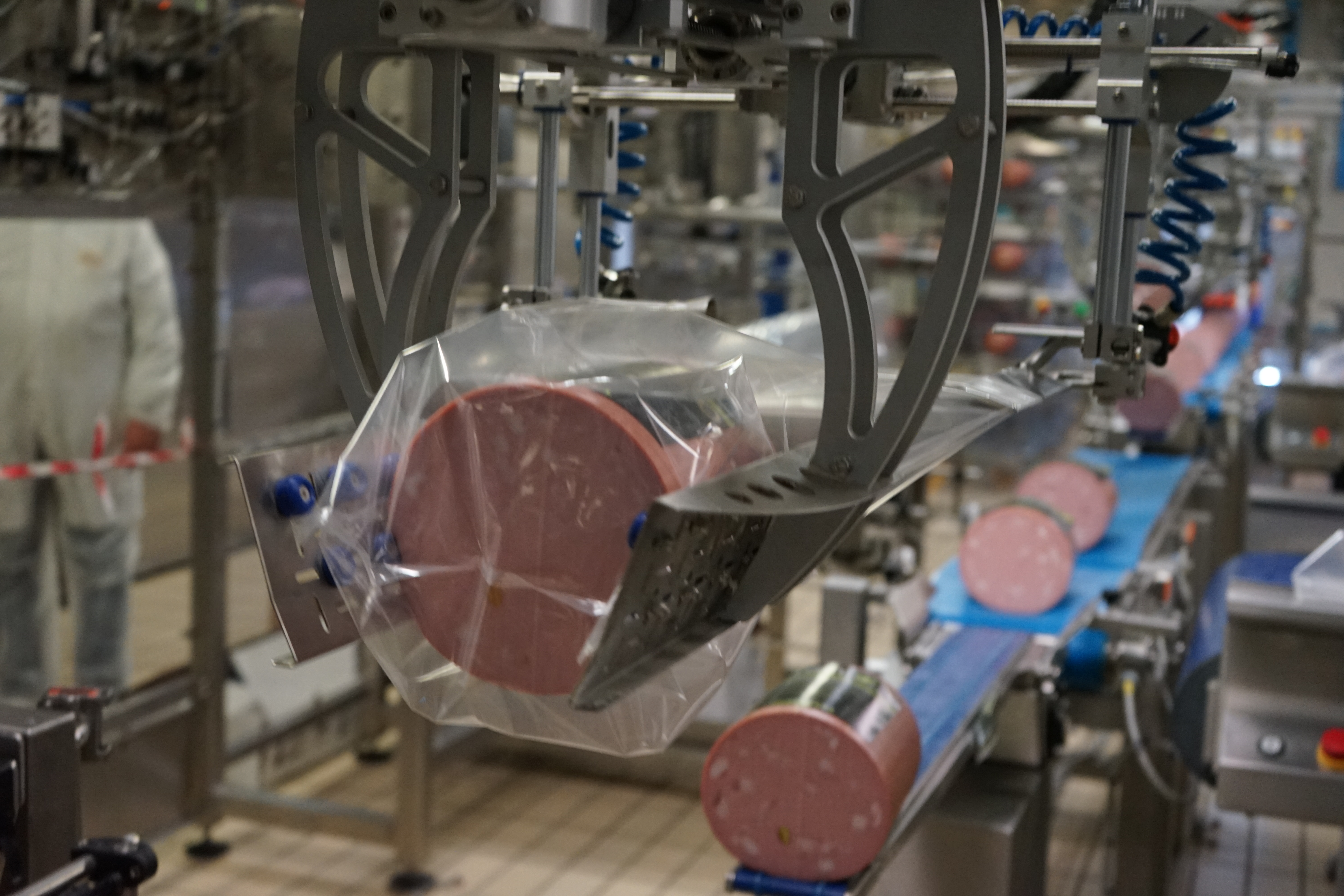

It is able to handle frames of great height and handled by AGVs and of suspended tray conveyors. When unloading, it is also possible to transfer one pole at a time to the packing or peeling lines, even with automatic bar extraction or loop cutting.

The special design mode, protected by international patents,reduces the cross-sectional footprint of the system (only 300 mm more than the length of the frames to be loaded or unloaded); it is the most compact and easiest system to fit into existing production facilities.

The compact loaders and unloaders for frames, trolleys, trees or suspended conveyors on which to place bars with hanging products can be fed either by manual product placement stations on the bars, by automatic loading devices for salami or other products on bars. We also offer a version that can be used both as a loader and an unloader. The design, derived from our TFRC loading system, allows customizations depending on the length of the hanging bars (poles), the size of the frames (or trolleys or tees or suspended tray conveyors), and the size of the products. In the case of semiautomatic loading, the insertion of the hanging bars into the loops is manual as is the effortless positioning into the hooks of the lifting catenary for subsequent storage in the programmed level. It is also possible to feed the loader with automatic salamis hanging machines to the bars.

All models move the arms that deposit the bars with the hanging cold cuts vertically, to adapt to the frames, which, with the same width, can have different heights and lengths, just as the heights of the levels to be loaded can be different, also depending on the product.

The compact loader, like the unloader, makes it possible to proceed with the formation of levels even while replacing a full frame with an empty one, of course in total safety.

Address

Fava Giorgio Axel s.r.l.

Via A. Cerati 19 A

43126 Parma

Italy

Telephone+39 0521 293734

Fax+39 0521 293968

Discover more from us