International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

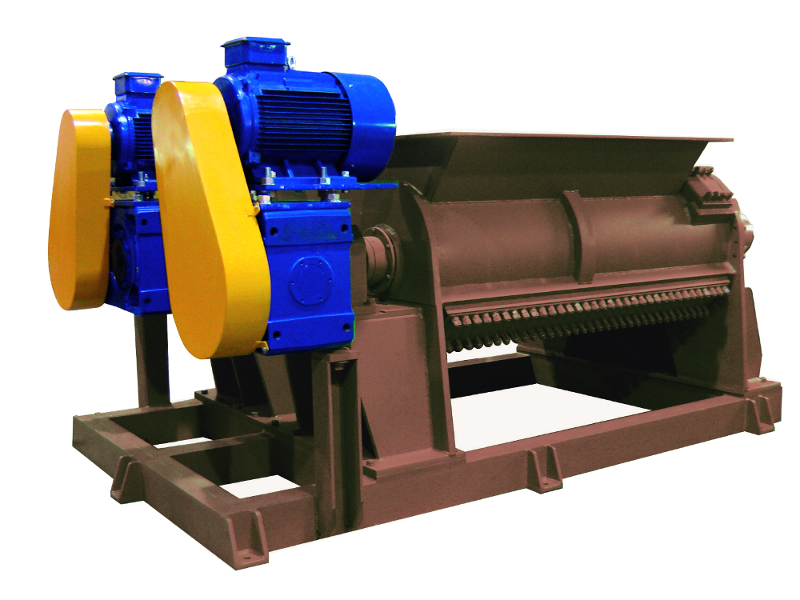

CONTINUOUS COOKER

Description

Used for the continuous cooking and de-hydration of raw or semi-finished butchery sub-products.

Our planning studies and experience acquired in the sector have allowed us to produce a highly efficient and technically advanced machine able to offer huge benefits for potential purchasers, such as:

1-A microprocessor (PLC) regulation and automation system has been adopted to control and manage all the phases and functions of the machine during processing: this permits energy savings, a reduction in personnel employed and constant quality control of the product treated. This equipment is provided with simple devices to interface with the operator such as functional alphanumeric keys to set and modify programs, graphical displays to visualise all the necessary information and a printer to record all the variables continuously in relation to time (e.g. Temperature).

2-The machine, complete with all transmission parts, is mounted on a strong base in a single block that makes it very easy to install in position.

3-Simplification of the mechanical coupling parts lightens servicing, consequently there is a reduction in maintenance costs.

4-ÍA special, unique "patented" mixed stuffing box ensures a seal in the support-bearings of the main shaft for the liquid generated while the product is cooking.

5-Its strong structure and use of very thick hightensile forged and the special steel alloys tested to standards regulations of CE give it the very important feature of lasting over time, having a positive effect on depreciation and maintenance costs. Another important feature is the use of special self-aligning bearings of leading international makes, housed in strong bolted spiders. The shaft control unit is composed of an electric motor provided with a hydrodynamic safety coupling, a parallel axis reduction unit and an additional oversized flexible mechanical coupling, the latter being of our manufacture. This dual protection allows the shaft to support sudden and considerable overloading.

The product is cooked by heating with indirect saturated steam at a pressure of 10 bars introduced through an appropriate rotating coupling-siphon into the main machine shaft composed of an Regulations of CE tested tube nest with a considerable radiating surface area.

The continuous cooker is supplied complete with every accessory for its normal operation (valves, variable measuring probes, control and checking instruments).

Address

Agricarnitec Santini e C. srl

Via Carlo Goldoni 7

20063 Cernusco Sul Naviglio Milano

Italy

Telephone+39 02 924 9089

Fax+39 02 924 5875