International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

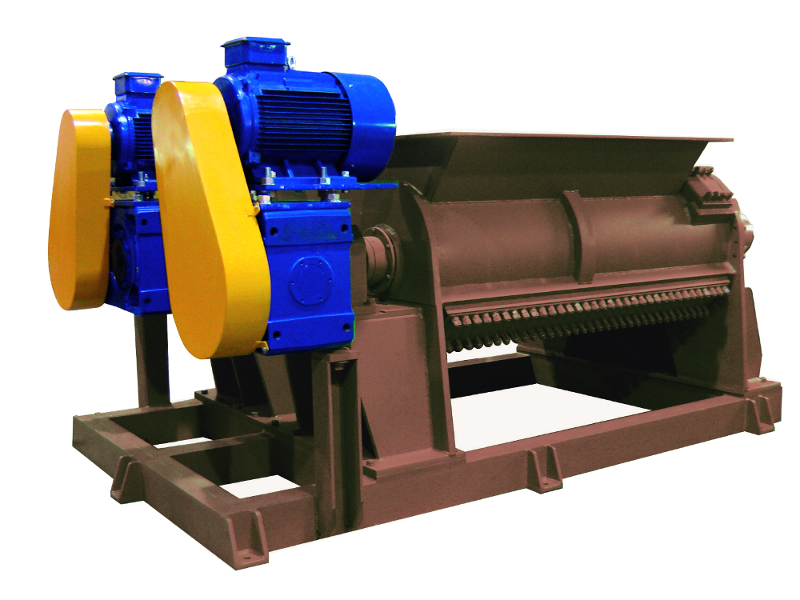

CONTINUOUS DRIER

Description

It is particularly suitable to dry powdered meat with a low fat percentage.

The drier presents the following characteristics:

- Easy installation: The machinery, included the whole transmission gearing, is assembled on a strong bed so as to make a single monobloc.

- High resistance to usury: Its strong structure, the use of special alloyed and stainless steels, the use of parts forged for high mechanical resistance enable it to last a long time and to reduce fixed and maintenance costs.

- Adjusting: A microprocessor controls the adjusting and automation system during all the processing steps and functions (feeding, heating, product outlet). It enables to save electric power, to reduce staff employment and it guarantees a constant quality control.

- Conveyance: Many superior-inferior check ports make it possible to check the product stand during the processing phases and to have an easy access to the axle during the cleaning and the ordinary maintenance.

- Maintenance: Maintenance costs are reduced to their minimum thanks to the easy installation of coupling and assembling parts.

- Transmission: The motion of the main axle is guaranteed by an electric motor equipped with a hydrodynamic security coupling, which is suitable to avoid transmission work overcharges, and by a right-sized parallel axle gear reduction unit.

WORKING:

The product drying process takes place by heating indirect saturated steam and putting in into the main axis of the machinery by means of a suitable rotary siphon-joint. The product’s stay period inside the machinery is governed by the inclination of the conveying blades situated on the axle and by the automatic/manual control of the outlet port. The non-stop drier is supplied with all the necessary fitting (valves, temperature feelers, control and checking instrumentation), electro ventilator, centrifugal separator, scrubber group to directly condense processing steam and to reemploy hot air.

Address

Agricarnitec Santini e C. srl

Via Carlo Goldoni 7

20063 Cernusco Sul Naviglio Milano

Italy

Telephone+39 02 924 9089

Fax+39 02 924 5875