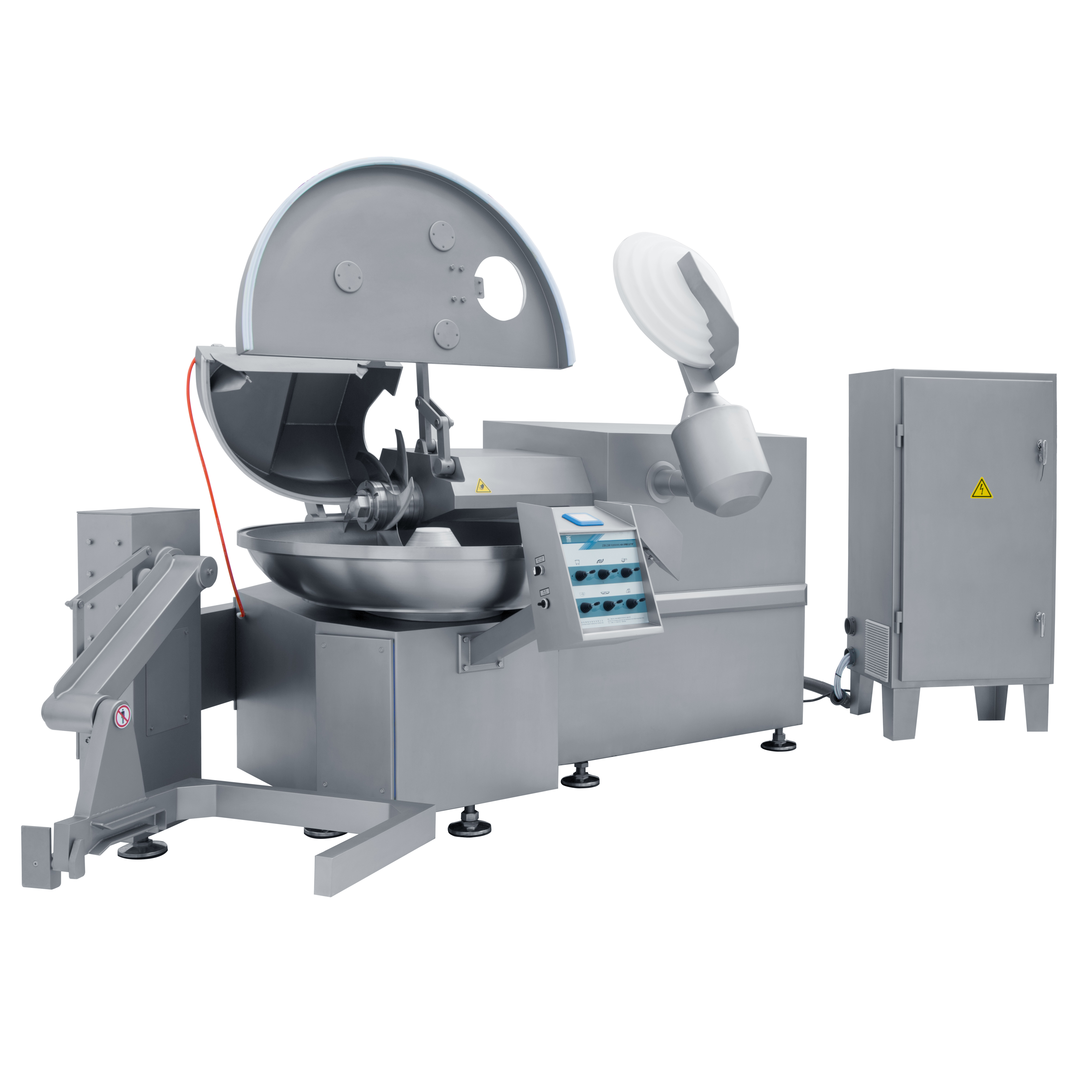

The bowl cutter machine you described is a highly advanced and efficient piece of equipment designed for the food processing industry, particularly for meat processing. Here's a summary of its key features and benefits:

Key Features:

Precision Engineering:

Key components are processed using a machining center to ensure high accuracy.

The machine uses high-quality imported bearings (SKF/NSK) for the main shaft, ensuring strong seismic resistance and long service life.

High-Speed Cutting:

The machine operates at speeds up to 3600 RPM, with frequency control for adjustable speed.

Equipped with 6 or 8 cutting knives made from imported materials, featuring high hardness, wear resistance, and excellent cutting performance.

Advanced Sealing and Safety:

The bearing seal employs four different sealing methods to prevent accidental damage.

The machine includes multiple safety features, such as protective switches that cut off power when the bowl cover is opened during operation.

Efficient Design:

The rotary bowl is made of cast stainless steel with a spill-proof edge, minimizing material loss.

The bowl cover is divided into front and back sections, with the front cover featuring a transparent feeding port for monitoring the cutting process.

Hydraulic System:

The machine uses a hydraulic system for feeding and discharging, improving efficiency and reducing material storage time in the bowl.

The hydraulic system includes high-quality YUKEN valve bodies and control components.

Temperature Monitoring:

An intelligent electronic temperature sensor monitors the material temperature during cutting, ensuring optimal processing conditions.

User-Friendly Operation:

The machine features a PLC-based human-machine interface for easy operation and storage of material formulas.

The discharge plate angle is adjustable, accommodating different consistencies of meat paste.

Durability and Rigidity:

The machine is constructed with thick carbon steel plates and reinforced with square tubes, ensuring high rigidity and stability.

The knife shaft box is made of 16mm SUS304 stainless steel, with internal reinforcing ribs for added strength.

Easy Maintenance:

The machine includes an automatic lubrication system for the main shaft, eliminating the need for manual refueling.

The rotary bowl has a water valve for easy drainage, and the bowl can be manually turned for cleaning when the back cover is open.

Noise and Vibration Control:

The machine undergoes vibration point elimination tests to ensure smooth operation at high speeds with minimal noise.

Benefits:

Enhanced Product Quality: The machine improves the emulsification effect, elasticity, and fineness of meat products, leading to higher-quality output.

Increased Efficiency: Hydraulic feeding and discharging, along with high-speed cutting, significantly boost productivity.

Safety and Reliability: Multiple safety features and robust construction ensure safe and reliable operation.

Ease of Use: The intuitive PLC interface and easy cleaning features make the machine user-friendly.

Durability: High-quality materials and advanced engineering ensure a long service life with minimal maintenance.

Applications:

This bowl cutter machine is ideal for processing various types of meat and auxiliary materials into chopped meat or meat paste. It is suitable for use in large-scale food processing facilities, ensuring consistent quality and high production rates.

Overall, this bowl cutter machine is a state-of-the-art solution for meat processing, combining precision, efficiency, and safety to meet the demands of modern food production.