International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Hebei Xiaojin Machinery Manufacturing Inc.

Hebei Xiaojin Machinery Manufacturing Inc.

Hebei Shijiazhuang

High-Tech Development Zone

No. 393 Yuhua East Road

050035

China

Telephone+86 311 6779 0077

Fax+86 311 8508 7288

About us

XiaoJin Machinery is qualified with modern and advanced equipments. We have CNC center, digital lathes, vertical processing center, high precision processing system and 3-D contact measuring machine, etc.

We have human resources managing system; we have a group of hard-working people leaded by high qualified engineers and technicians whom have created and developed more than one hundred models of food processing machines. Many items of our machines are patented.

All product adopt to CAD design, mainly manufacture three big series ,59 kinds, 100 models of food processing machinery, including meat filler, clipper, slicer, frozen meat flaker, meat grinder, meat cutter, mixer, saline injector, tenderizer, vacuum tumbler,slicer, dicer, smokehouse etc.

The concept of seeking the best quality is the core of “xiaojin spirit”. Xiaojin group have established a comprehensive administrative system for quality management and control since the group found, the general manager bears the brunt of quality supervision, supervises every single detail and implement the quality control regulation strictly. The group practice “three inspection system” for all important production procedure, the system provides the inspection in the first, middle and final product stage, so that can ensure the best quality for every machine.

In Xiaojin group, every one takes the company’s goal as their targets,which helps for the 100% qualified products. It is not the only you can get at XiaoJin. The comprehensive service system consisted of pre-sell, in-sell and after-sell service will let you know more of the value in Xiaojin Machinery. All of this allow Xiaojin group to gain the praise from the world machinery industry and the respect from customers all around the world!

Keywords

- Bowl cutter

- Sausage filler

- Sausage clipper

- Meat grinder

- Smokehouse

Our Products

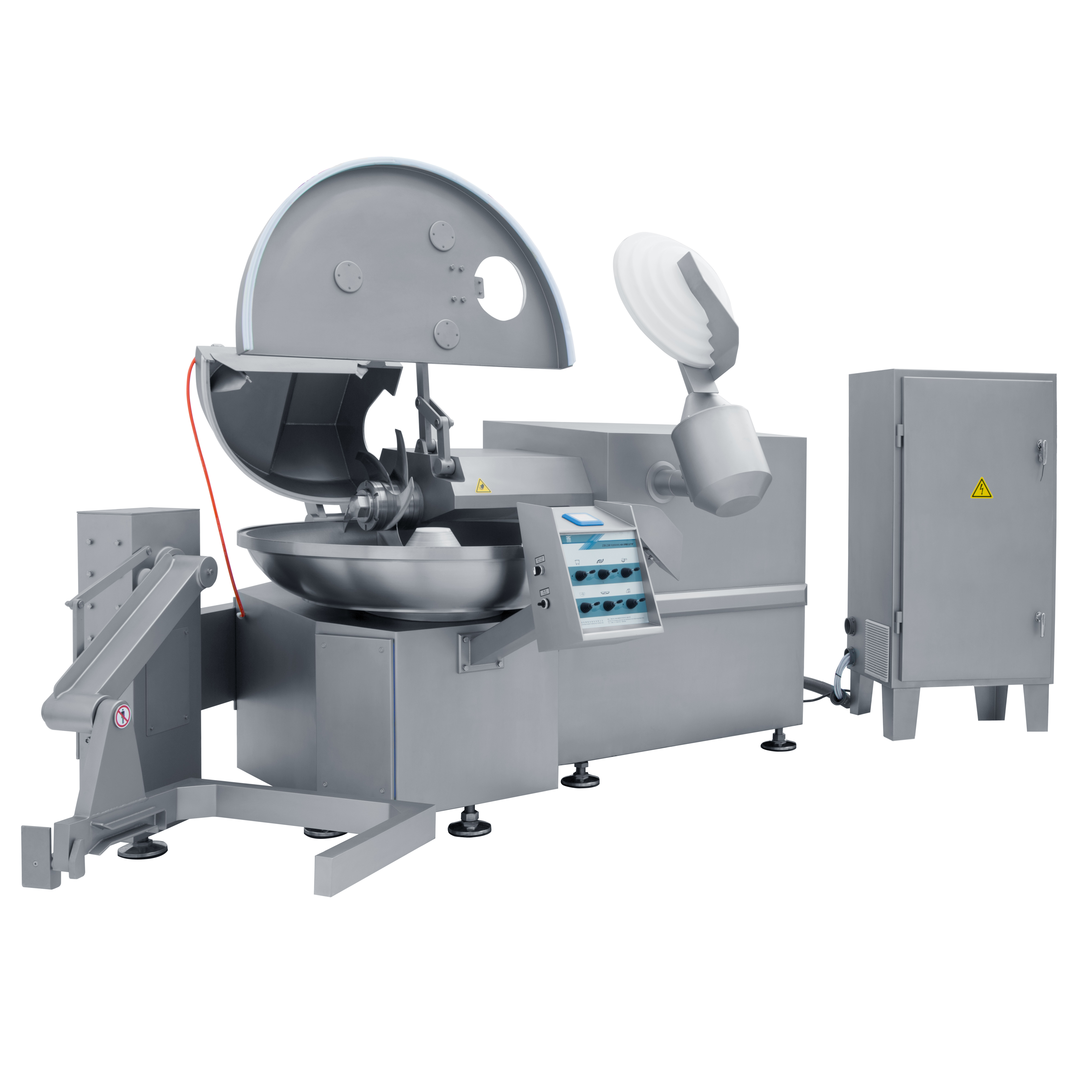

Bowl Cutter

The bowl cutter machine you described is a highly advanced and efficient piece of equipment designed for the food processing industry, particularly for meat processing. Here's a summary of its key features and benefits:

Key Features:

Precision Engineering:

Key components are processed using a machining center to ensure high accuracy.

The machine uses high-quality imported bearings (SKF/NSK) for the main shaft, ensuring strong seismic resistance and long service life.

High-Speed Cutting:

The machine operates at speeds up to 3600 RPM, with frequency control for adjustable speed.

Equipped with 6 or 8 cutting knives made from imported materials, featuring high hardness, wear resistance, and excellent cutting performance.

Advanced Sealing and Safety:

The bearing seal employs four different sealing methods to prevent accidental damage.

The machine includes multiple safety features, such as protective switches that cut off power when the bowl cover is opened during operation.

Efficient Design:

The rotary bowl is made of cast stainless steel with a spill-proof edge, minimizing material loss.

The bowl cover is divided into front and back sections, with the front cover featuring a transparent feeding port for monitoring the cutting process.

Hydraulic System:

The machine uses a hydraulic system for feeding and discharging, improving efficiency and reducing material storage time in the bowl.

The hydraulic system includes high-quality YUKEN valve bodies and control components.

Temperature Monitoring:

An intelligent electronic temperature sensor monitors the material temperature during cutting, ensuring optimal processing conditions.

User-Friendly Operation:

The machine features a PLC-based human-machine interface for easy operation and storage of material formulas.

The discharge plate angle is adjustable, accommodating different consistencies of meat paste.

Durability and Rigidity:

The machine is constructed with thick carbon steel plates and reinforced with square tubes, ensuring high rigidity and stability.

The knife shaft box is made of 16mm SUS304 stainless steel, with internal reinforcing ribs for added strength.

Easy Maintenance:

The machine includes an automatic lubrication system for the main shaft, eliminating the need for manual refueling.

The rotary bowl has a water valve for easy drainage, and the bowl can be manually turned for cleaning when the back cover is open.

Noise and Vibration Control:

The machine undergoes vibration point elimination tests to ensure smooth operation at high speeds with minimal noise.

Benefits:

Enhanced Product Quality: The machine improves the emulsification effect, elasticity, and fineness of meat products, leading to higher-quality output.

Increased Efficiency: Hydraulic feeding and discharging, along with high-speed cutting, significantly boost productivity.

Safety and Reliability: Multiple safety features and robust construction ensure safe and reliable operation.

Ease of Use: The intuitive PLC interface and easy cleaning features make the machine user-friendly.

Durability: High-quality materials and advanced engineering ensure a long service life with minimal maintenance.

Applications:

This bowl cutter machine is ideal for processing various types of meat and auxiliary materials into chopped meat or meat paste. It is suitable for use in large-scale food processing facilities, ensuring consistent quality and high production rates.

Overall, this bowl cutter machine is a state-of-the-art solution for meat processing, combining precision, efficiency, and safety to meet the demands of modern food production.

Vacuum filler

A vacuum sausage filler is a specialized equipment designed for filling meat paste or other filling materials into casings to produce sausages. It plays a crucial role in the meat processing industry, enabling efficient and precise completion of the sausage filling process.

Key Features:

Vacuum Filling Process:

The filling process is performed under a vacuum state, which prevents fat oxidation and proteolysis, reduces bacterial survival, and ensures a longer shelf life, brighter color, and pure taste of the products.

Automatic Casing Knot Tying Device:

Equipped with an automatic casing knot tying device suitable for animal casings, protein sausage casings, collagen casings, etc.

Stuffing speed can reach up to 500 sausages per minute.

Can be connected to a sausage length controller for high-speed knot tying.

Precision Portion Control:

Each portion can be adjusted from 5g to 99,999g.

The allowed error for paste products is ±2g (for a 400g portion).

Automatic Production:

Can be connected to a double clipping machine for fully automated production.

High-Quality Components:

Key parts are produced by a machining center with high precision.

The pump, impeller, and blade undergo special heat treatment, ensuring a highly smooth surface for easy cleaning.

Advanced Control System:

Features a human-machine interface, servomotor, decelerator, and PLC controller, all of which are imported products.

The vacuum degree can reach up to -0.1 MPa.

Integration with Other Equipment:

Can be linked with an automatic sausage hanging machine and a high-speed sausage length controller for seamless production.

Durable and Hygienic Design:

The entire machine is made of SUS304 stainless steel plate.

Unique exterior design and surface processing techniques ensure durability and compliance with hygiene standards.

Applications:

The vacuum sausage filler is widely used in the meat processing industry for producing high-quality sausages with consistent texture, color, and taste. It is suitable for various types of casings and can handle large-scale production efficiently.

Benefits:

Improved Product Quality: Vacuum filling ensures longer shelf life, brighter color, and better taste.

High Efficiency: Fast filling and knot tying speeds increase productivity.

Precision and Consistency: Accurate portion control and minimal error ensure uniform product quality.

Hygienic and Easy to Clean: High-quality materials and smooth surfaces make cleaning and maintenance simple.

Automation: Integration with other machines enables fully automated production, reducing labor costs.

This vacuum sausage filler is an essential tool for modern meat processing facilities, combining advanced technology, precision, and efficiency to meet the demands of high-quality sausage production.

Sausage clipper

Automatic Sausage Clipper can be connected with filling machine to form an auto production line of filling, sealing, cutting, thus labour intensity can be reduced, quality of products can be raised, and your products will become more competitive.

The machine is motivated by electric motor. Clipping is completed by sets of cams. The structure is compact and transmission is reliable. The body of the machineDKJC15 is made of high quality aluminum alloy,DKJC12、DKJC18/15made of high quality stainless steel, its main parts and transmission parts are made of stainless steel and high grade steel. Its comprehensive features and corruption risitance can all meet your needs in production.

For the safety sake, there should connect a ground line after the machine settled.

1. Brief Introduction to the Structure

The machine is controlled by electromagnetic clutch. It consists mainly of stand, body, outlet part, pneumatic system, operation device, wire coil trestle, moving trestle, etc.

2. Main Technical Data

A. Measurement: L×W×H=760×750×1770mm

B. Total weight: about 500kg

C. Height between clipping center and ground: 920-1060mm

D. Rate of clipping: DKJC12:60-150times/minute ; DKJC15:50-100times/minute; DKJC18:30-100times/minute

E. Power of motor: 3.5kw

F. Power supply: three phase currentAC380V

G. Pneumatic source: Working pressure: 0.5-.06Mpa

H. Pneumatic consumption: 0.0064m³/minute

I. Clip used: Great Wall aluminum clip

J.Range of fold diameter: DKJC12:25-60mm,DKJC15:40-120mm, DKJC18/15:40-200mm

Meat Grinder

a.Structure: The machine is composed of stainless steel outer casing, feeding screw, decelerator, knife, knife plate, bearing circle, pressing ring and electric box.

b.Principle: During mincing, the turning feeding screw push the material in the hopper forward to pre-mincing knife plate, and minced into pieces by the power between holes of the knife plate and the edges of the knife. And minced meat then flow out from the holes by the rotation of feeding screws.

Smokehouse

YX Series Automatic Smokehouse have many functions such as smoking, cooking, drying, steaming, etc. And it can customize with cooling system to realize cooling smoking function as per customer’s request.

Chapter two: Features and main technical parameter:

1、Features:

(1)YX Series Automatic Smokehouse adopts assembled machine box structure, one trolley space as one unit. Machine box of every unit adopts completely high pressure polyurethane PU foam, with good heat insulation property. Every unit has independent wind chamber, mutual non-interference cyclic wind; adopts double speed motor and special wing type centrifugal impeller, the max speed of top part can reach 24m/s, the speed of bottom part can reach 4m/s, adopts low rotate double speed fan motor, which will increase the motor’s service life; unique air duct design and independent wind chamber make the inside an even turbulent flow field, which can mostly guarantee products to be ripping evenly during cooking, drying, and steaming process, and mostly guarantee the the products be colored evenly during smoking process. The door of smokehouse adopts completely polyurethane PU foam with high entire strength, adopts imported silicon seal strip with good sealing effect and long service life; the front and back end of machine box baseplates are designed into fixed cantboard, no need for turnover style guide rail, can make trolley enter smokehouse directly, which avoid pollution caused by turnover style guide rail.

(2)YX Series Automatic Smokehouse adopts advanced PLC / PC computer control system, can store many different craft formula, operation is easy and reliable.

(3)YX Series Automatic Smokehouse adopts wood chips smoke generator. External wood chips smoke generator can reach normal smoke effect within one minutes.

(4)YX Series Automatic Smokehouse adopts channel type with front and back doors or one side door type. There is detecting device installed on the top of door to check if the door is closed well. If customer request, it could adopts interlock device.

(5)YX Series Automatic Smokehouse adopts cleaning system in every set smokehouse. Easy and convenient to operate and can clean the smokehouse completely.

(6)YX Series Automatic Smokehouse adopts domestic and internal well known brand electrical components, and we can customize electric components as per customer’s request.

Main technical parameter:(Commonly used models)

Steam Heating

(1)YXQ1/1:One door one trolley automatic steam heating smokehouse

External dimension: (L)x(W)x(H) 1330x2223x3140

Production capacity: Max 250kg

Total power: 5kw

Air consumption: Max 40kg/h

High steam pressure:0.6-0.8Mpa

Low steam pressure:≤0.1Mpa

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

(2)YXQ1/2:One door two trolleys automatic steam heating smokehouse

External dimension: (L)x(W)x(H) 2439x2223x3140

Production capacity: Max 500kg

Total power: 9kw

Air consumption: Max 80kg/h

High steam pressure:0.6-0.8Mpa

Low steam pressure:≤0.1Mpa

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

(3)YXQ2/2:Two doors two trolleys automatic steam heating smokehouse

External dimension: (L)x(W)x(H) 2439x2223x3140

Production capacity: Max 500kg

Total power: 9kw

Air consumption: Max 80kg/h

High steam pressure:0.6-0.8Mpa

Low steam pressure:≤0.1Mpa

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

(4)YXQ1/4:One door four trolleys automatic steam heating smokehouse

External dimension: (L)x(W)x(H) 4650x2223x3140

Production capacity: Max 1000kg

Total power: 17kw

Air consumption: Max 160kg/h

High steam pressure:0.6-0.8Mpa

Low steam pressure:≤0.1Mpa

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

(5)YXQ2/4:Two doors four trolleys automatic steam heating smokehouse

External dimension:(L)x(W)x(H) 4650x2223x3140

Production capacity: Max 1000kg

Total power: 17kw

Air consumption: Max 160kg/h

High steam pressure:0.6-0.8Mpa

Low steam pressure:≤0.1Mpa

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

Electric heating

(1)YXD1/1:one door one trolley electric heating smokehouse

External dimension: (L)x(W)x(H) 1330x2223x3140

Production capacity: Max 250kg

Total power: 29kw

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

(2)YXD1/2:one door two trolleys electric heating smokehouse

External dimension: (L)x(W)x(H) 2439x2223x3140

Production capacity: Max 500kg

Total power:57kw

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

(3)YXD2/2:Two doors two trolleys automatic electric heating smokehouse

External dimension: (L)x(W)x(H) 2439x2223x3140

Production capacity: Max 500kg

Total power:57kw

Compressed air pressure:≥0.4Mpa

Water supply pressure: ≥0.4Mpa

Our Contact Persons

Aimee MI

Sales

Sales Representative/Agent

Ryan CHAI

Sales

Head of Department

Lisa Gao

Sales

Sales Representative/Agent

Our Events

Machine Demonstration

Machine Demonstration

Machine Demonstration

Machine Demonstration

Machine Demonstration