International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

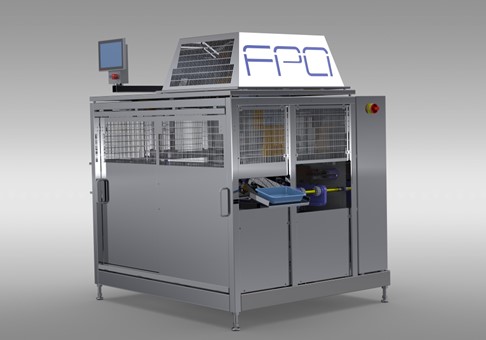

Robot Line for 25 g. sausage products

Description

Sorting and packaging lines - pick & place units

There are always new challenges or requirements for machines in our customers' production areas. We are happy to take on these requirements and develop new machines and applications.

Here we would like to present a FPA packaging solution that we designed and implemented for a German customer:

The system was designed in 2022 for separating and packaging the 25 g. mini products. After a corresponding development and design phase, the two systems were delivered and put into operation at the end of March and the end of May 2023.

The systems are used to automatically separate and align small sausage products in order to place them in the open molds of the packaging machine at the end of the line.

Before starting the system, the system operator fills the centrifuge with the 25 g liver sausage or tea sausage products. The centrifuge achieves an output of 300 pieces per minute for small products.

The products are conveyed on a round belt conveyor under a labeler and labeled. This is followed by a camera system. It checks the position of the labels and whether they have a corresponding best-before date printed on them. If one of the two points is not met, the product is immediately removed from the product flow.

The products that are deemed to be good then reach the robot cell and are put together in groups of 2 x 5. The delta picker moves to this parking position with its gripper system and removes the products from the nest to then place them in the free thermoforming molds. This procedure is repeated until the entire format set is filled.

The robot cell control system then sends a release signal to the packaging machine, which then starts its next cycle. Once this cycle is complete and the feed has started, the pick & place cell is given the go-ahead to pack additional products into the next available deep-drawing molds.

The system can be used universally because it can process a wide range of other product dimensions by exchanging the transport chain and gripper. The overall performance of the system depends on the length, weight and caliber of the products and the corresponding fill level in the centrifuge.

Address

FPA GmbH

In der Mark 2

33378 Rheda-Wiedenbrück

Germany