International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

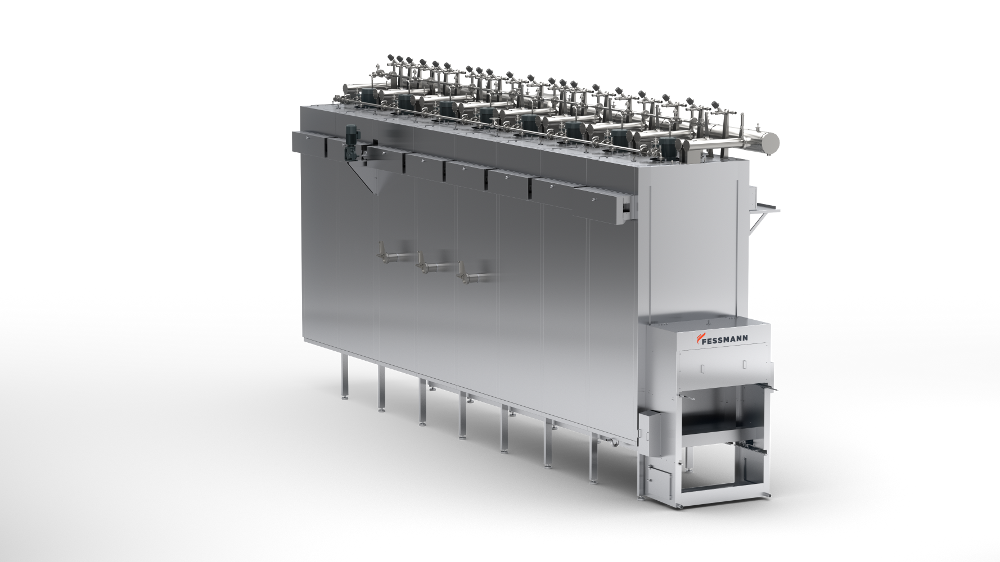

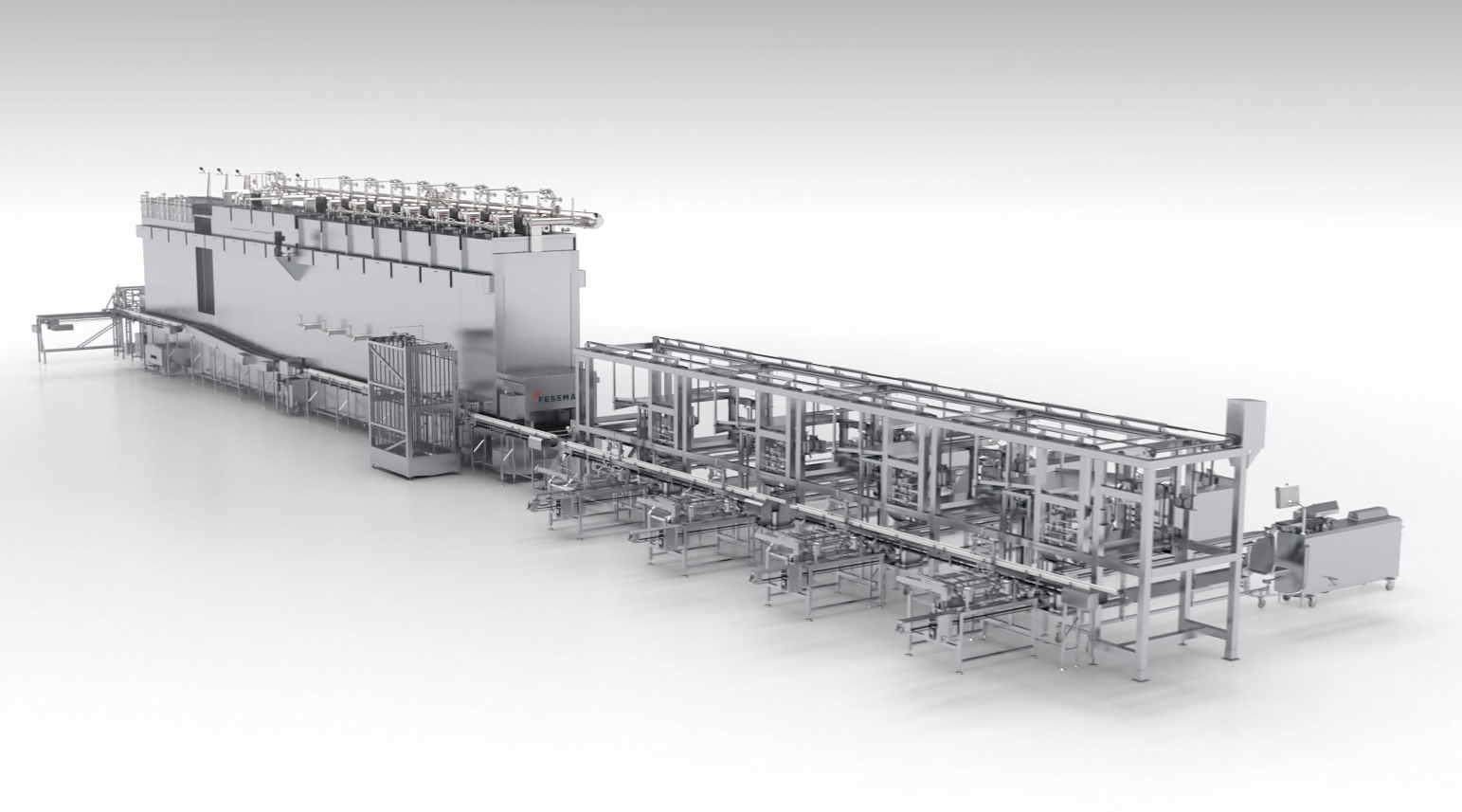

Semi-continuous universal systems

Description

The systems TF3000 and TFi3000 offer an economical combination of smoke, heat and cold treatment for the industrial batch production. Automated processes increase your production capacity and reduce operating costs. The filled trolley is placed manually in front of the heating chamber and from there the pneumatic transport system of the TF3000 /TFi3000 pulls the trolleys into the center of the heating chamber. Subsequently, the process control is activated and starts a determined product program. The heating program now runs fully automatically according to the predefined program. After completing this phase, the trolleys are automatically transported into the cooling zone. In accordance to the desired condition of the goods and the intended packaging, your products are immediately cooled down to packaging temperature using continuous shower, intermitted shower and chilled air to achieve a just-in-time production of your products. At the same time the first batch is cooled, the next batch can already been processed in the cooking and smoking section of the system. In this semi-continuous system you benefit from the full flexibility of a universal batch system with the economic advantages of a highly automated production line.

Address

Fessmann GmbH und Co. KG

Herzog-Philipp-Str. 39

71364 Winnenden

Germany

Telephone+49 7195 7010

Fax+49 7195 701105