International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

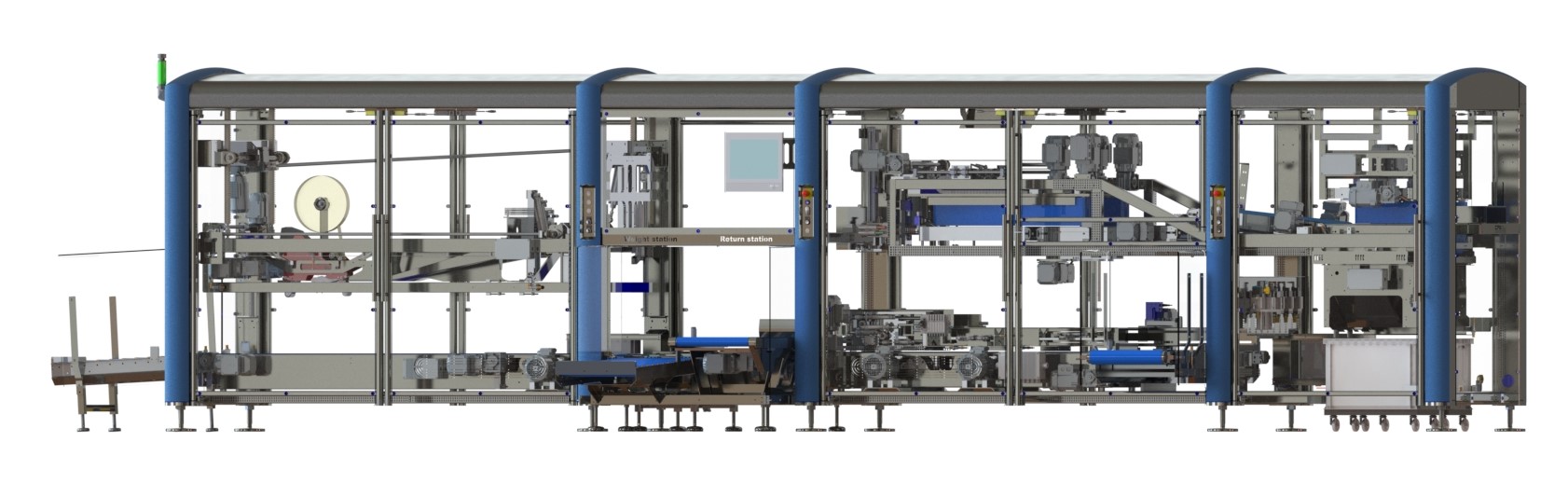

CP 201 Gravity Casepacker

Description

For a wide range of applications

The CP 201 gravity case packer has been specifically developed for horizontally packing deep-frozen products in boxes at high speed, in combination with a highly compact footprint. Typical products include frozen French fries, vegetables, meat and fish. Our CP201 case packer is capable of greater kg/m3 packing performance than any other machine.

Features

- CPS can pack more kilograms of product/m3 performance than any other supplier

- Fully quality-monitored bag handling from the form fill seal machine to the case packer unit, and highly effective special vibration volume reduction techniques

- Fully menu-controlled and good accessibility for servicing

High-quality stainless steel and aluminium components

The CP 201 casepacker system provides for the positioning and the filling of bags into carton boxes in programmable patterns.2 vertical conveyor belts assure the correct centre line positioning of the bags for the following bag turning unit. This bag turning unit consists of 2 conveyor belts positioned parallel to each other which are running at variable speeds. After the bag turning unit the bags will be presented, turned or not, to the collect belt. On this frequency controlled collect belt a preset number of bags (can be set in the menu) can be accumulated (with or without partial overlap). This group of bags will then be introduced to the casepacker unit, which is equipped with pneumatic bomb doors and a patented bag in-feed unit. This bag in-feed unit is equipped with 2 vertical conveyor belts which are adjustable in width to reduce the volume of the passing bags during transfer to the bomb doors of the casepacker. The vertical belts can also move left or right and can in this way deposit rows of bags in different positions on the bomb doors in order to pack more rows per layer in the carton. The casepacker is completely menu controlled for instant and easy setting of all preset bag and carton sizes and packing patterns.

- Length = 3300 mm.

- Width = 1160 mm (2650 doors open)

- Height = 1950 mm (2320 hoods open)

- Max. bags per row 4.

- Max. bags per carton 99

Technical specifications

- Capacity 140 bags/minute(with a minimum of three bags per collect)

- Machine housing stainless steel / aluminium

- Controls IPC all settings menu controlled

- Operator interface

- Colour touch screen TFT with integrated PC and modem facility

- Control panel fitted on a swivel arm