International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Description

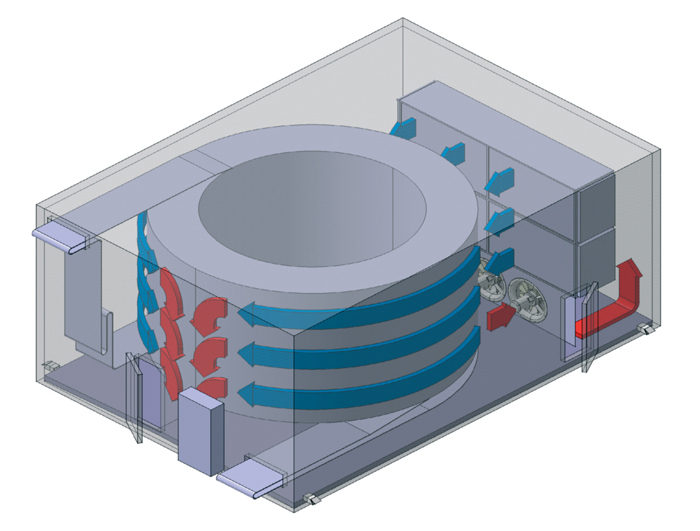

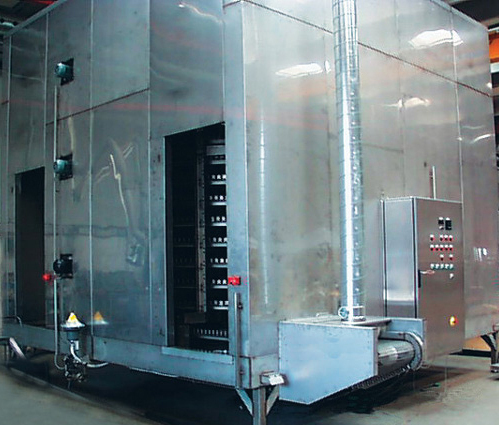

The resource-saving SingleStacker freezer from Scanico, with its unique belt stacking system, is presumably one of the most effective spiral freezers on the market when it comes to freezing capacity compared to space and energy consumption.

The SingleStacker offers you:

- The most compact spiral freezer on the market — with up to 30% lower total freezer height compared to traditional spiral freezers

- Up to 30% lower freezer energy consumption compared to traditional spiral freezers

- Full space between tiers available for products

- No risk of product jam — meaning: less waste, less cleaning and maximum up-time

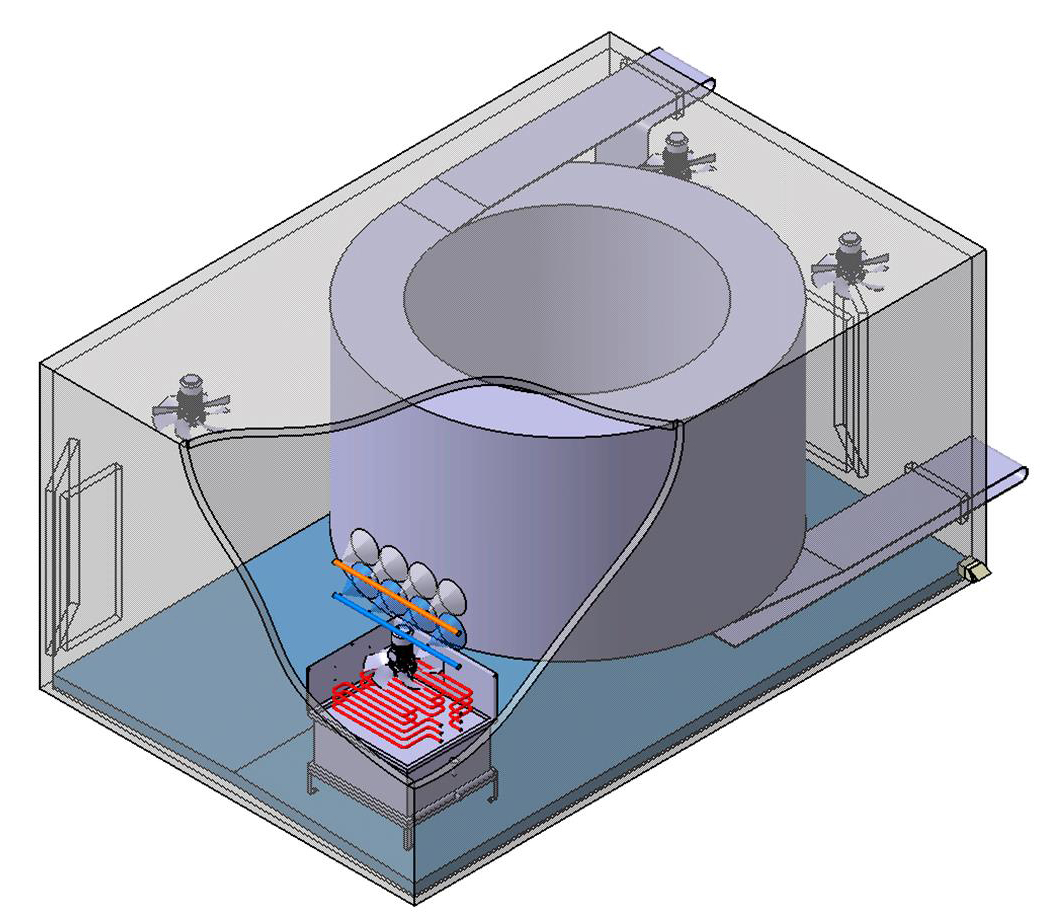

Your products decide the height of the side links and size of the spiral. The SingleStacker is available for product heights up to 110 mm, and belt width is available up to 1000 mm effective belt width. The low belt stack also reduces the air volume needed and minimises energy consumption. In- and out-feed in the same pressure zone, a unique air balance, together with wide evaporator fin spacing, enables long running time between defrosts — up to one week depending on product.

The right belt solution for the SingleStacker is chosen on the basis of your product’s consistency and packing as well as the intended treatment. We can use a stainless steel collapsing belt for most of the products, a space-saver belt with a fixed inside edge for shape-sensitive products such as raw fish fillets or polyethylene belts with high carrying support for soft and sticky products such as proofed dough.

The SingleStacker can be supplied with a range of cleaning systems, from belt washer to complete CIP systems and is available in all types of layouts – your production guides the design.