International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

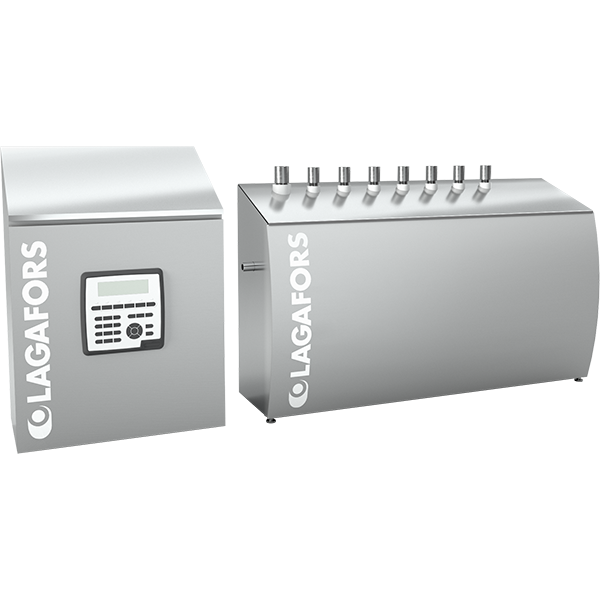

Low Water Pressure Mobile – LWP-M II

Low Water Pressure Mobile – LWP-M II

Description

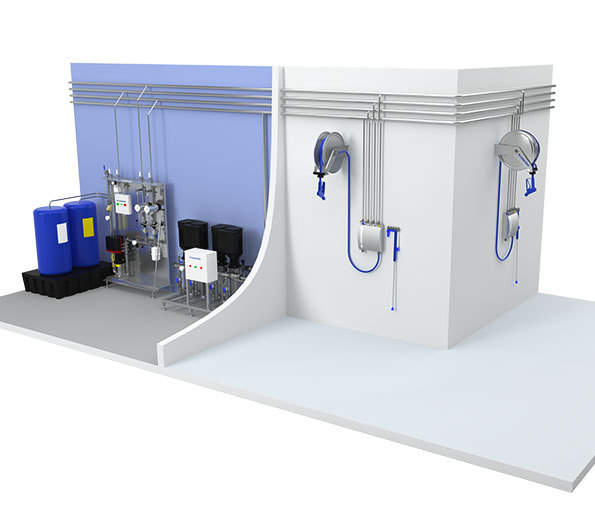

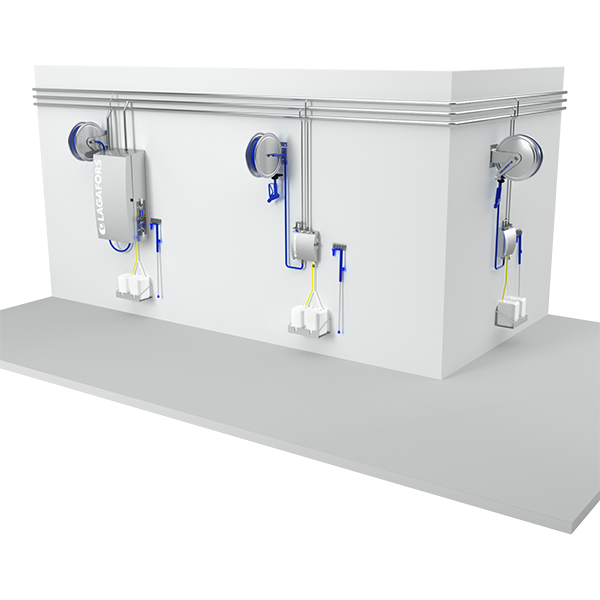

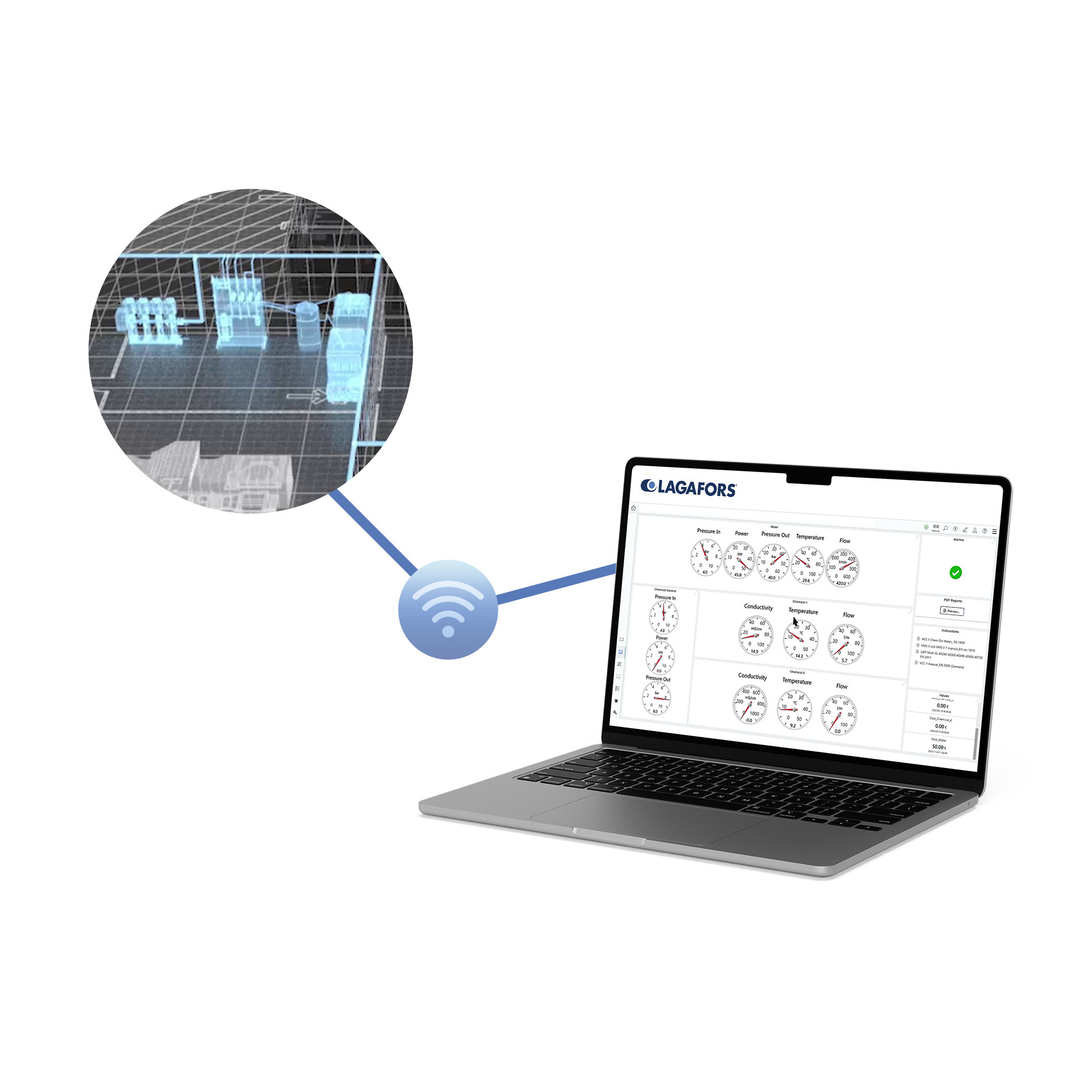

Lagafors® Low Water Pressure Mobile, LWP-M II, is a complete mobile cleaning equipment for flushing with pressurised water and application of chemical foam and disinfectant. The LWP-M II is built on a stainless steel frame with two rear pivot wheels for smooth and efficient movement. The unit consists of a frequency controlled low pressure pump, a compressor for pressuried air, injector and suction hoses for chemicals. Two 25 litres chemical containers can be placed on the trolley which also provides holders for hose and nozzles. LWP-M II has a hygienically designed cabinet made in stainless steel that can easily be opened for service and maintenance.

The unit should primarily be seen as a complement to other cleaning equipment. External air supply is recommended for daily use (The unit is then delivered without compressor).

The LWP-M II is especially appropriate for cleaning applications in food processing, e.g. in slaughterhouses, meat processing, dairies, breweries, fish industries, prepared food industries, industrial kitchens and other places where a high level of hygiene is required.

• Working pressure 20-25 bar alternatively 40 bar.

• Mobile unit with a smooth trolley for easy transportation.

• Easy to install; simply connect water and electricity.

• 20 meters hose, spray gun and nozzles for rinse, foam and disinfection are included.