International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Decentralized Cleaning System – DCS

Decentralized Cleaning System – DCS

Description

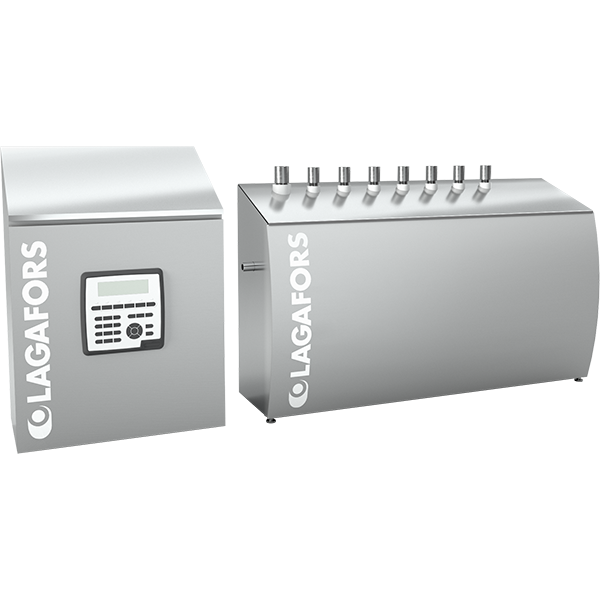

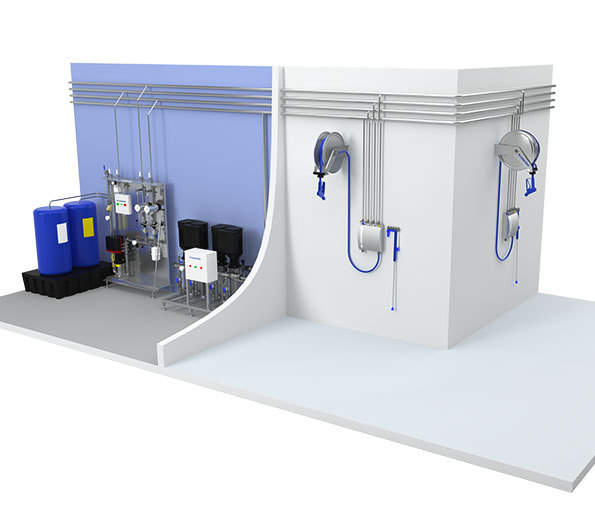

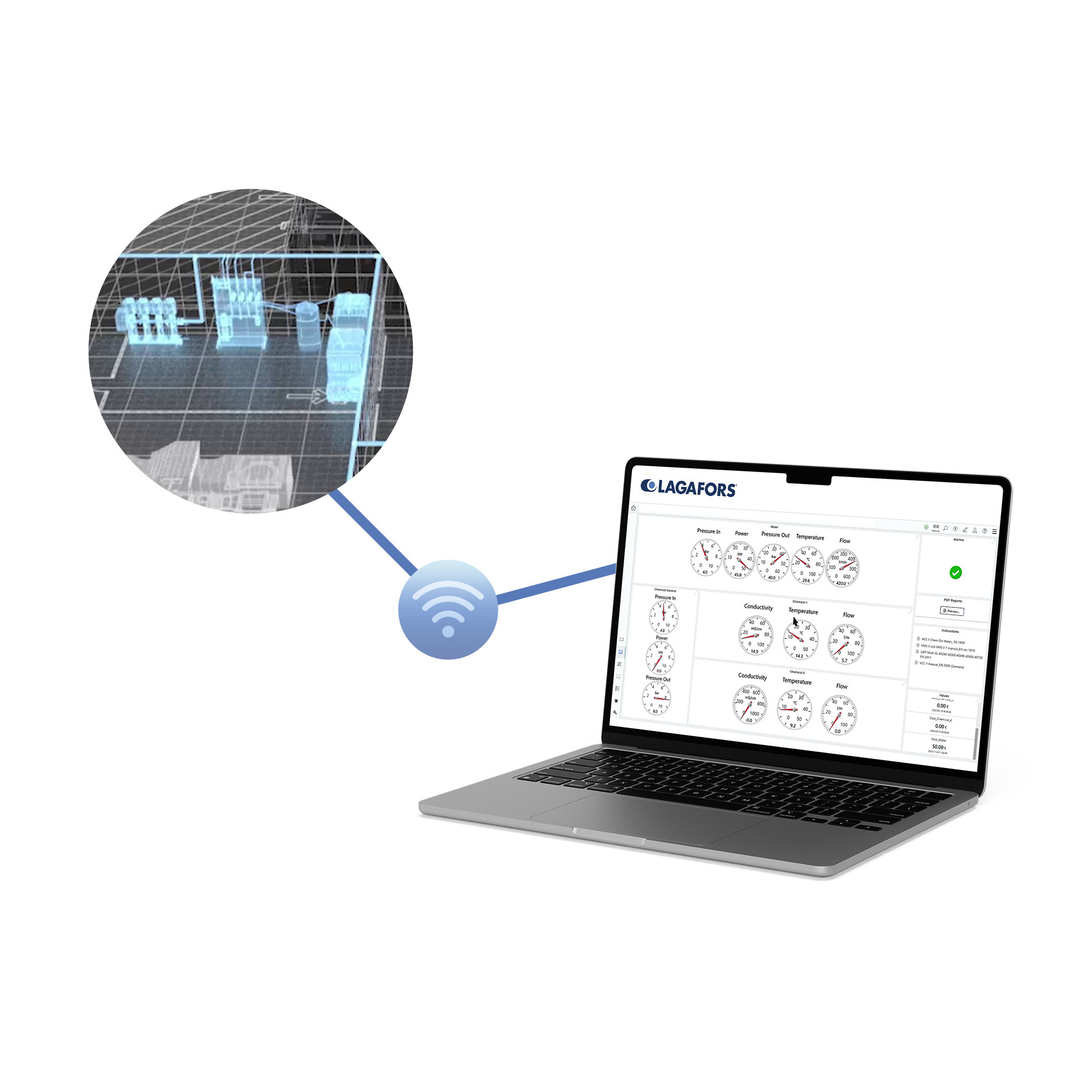

Lagafors® Decentralized Cleaning System, DCS, helps companies in the food industry achieve first-class hygiene while at the same time delivering flexibility in the cleaning process. The DCS cleaning system is comprised of four main components that together comply with the highest capacity, performance and quality standards. The main components supply the right pressure, flow and solution concentration to the places where they are needed.

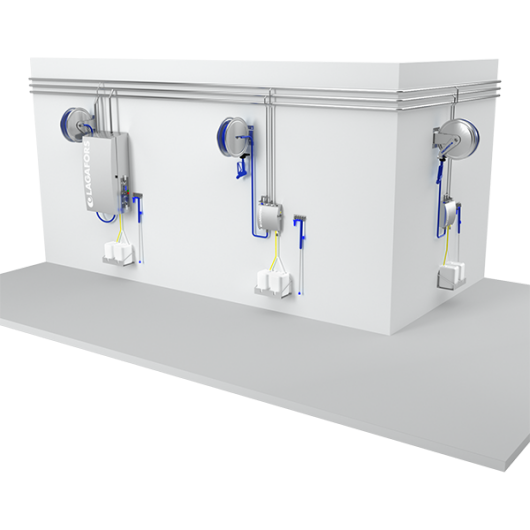

The customer can choose between placing the pump unit with integrated satellite (CB) in the production area or a pump unit (SB/Multi) outside the production area. If possible, we recommend the latter solution. Pipes are then drawn from it to the satellite units. Pipes are drawn from it to the satellite stations. Each satellite station is comprised of a hose reel with hoses for water, chemical solution and disinfectant solution.

The Lagafors DCS is suitable for installations of all sizes, but when using larger systems (>5 satellites), you should also consider installing a Lagafors CCS, Central Cleaning System.