International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

SAIREM

Address

SAIREM 82 Rue Elysee Reclus

69150 Decines Charpieu

France

Discover more from us

About us

Your partner in Microwave & Radio Frequency professional solutions, SAIREM brings 45 years of expertise in MW and RF technology, delivering tailored solutions for the food industry’s most demanding challenges.

With a strong presence in over 70 countries through an extensive network of agents, SAIREM provides cutting-edge equipment for tempering, pasteurization, drying, extraction, decontamination, and more.

Our high-performance systems guarantee efficiency, precision, and food safety across various applications, treating products such as herbs and spices, vegetables, fruits, meats, fish, seafood, essential oils, seeds, and even insects.

Our team of microwave and RF experts leverages advanced modeling and simulation tools to optimize processes, ensuring maximum efficiency, uniformity, and energy savings. SAIREM can develop customized machines tailored to your exact needs, adapting our equipment to your specific products and quality requirements.

SAIREM provides the expertise, technology, and support to ensure seamless integration, enhanced productivity, and reduced operational costs.

MW and RF for speed and safety

SAIREM’s microwave (MW) and radio frequency (RF) systems optimize the tempering, cooking, drying, heating, and pasteurization of a wide range of products, including meat and ready-to-eat meals.

The use of microwaves is a thermal process that rapidly heats from the inside out, enables precise temperature control. This results in consistent processing, preserving the taste, texture, and color of the food while maintaining its nutritional value.

The speed of the process, combined with accurate temperature settings, ensures high quality and efficiency and minimizes bacterial growth, enhancing food safety.

Another key advantage is that SAIREM’s equipment is 100% electric and energy-efficient, reducing energy consumption while producing zero greenhouse gas emissions at the production site. This makes it a sustainable and eco-friendly solution for the food industry.

Tempering

Whether for meat, seafood, vegetables, butter, or fruits, SAIREM’s microwave tempering technology preserves product quality while reducing processing time and minimizing drip loss.

SAIREM’s microwave tempering systems offer a significant leap forward in food processing efficiency, delivering faster, more precise, and energy-efficient solutions compared to conventional methods.

With SAIREM’s solutions manufacturers can optimize their production lines for flexibility, consistency, and reduced operational costs and space, all while maintaining the highest standards for food quality.

Drying

For insects drying, especially for insect protein sources like mealworms, microwaves provide similar benefits, ensuring quick and uniform drying and moisture removal that preserves organoleptic properties and natural shape of the insects.

For herbs and spices drying, microwaves work 2-15 times faster than traditional hot-air methods, while preserving appearance, active ingredients, and flavor, with reduced energy consumption.

Other applications, such as drying cheese chips, show the flexibility and modularity of microwave technology, enhancing product quality with energy-efficient, fast, and homogenous processes across different industries.

Compared to conventional methods, SAIREM’s solutions offer significant benefits, including uniform volumetric heating for consistent results, selective drying that quickly evaporates moisture while preventing overheating or degradation.

Pasteurization

As the global Ready-to-Eat (RTE) market continues to expand, SAIREM’s microwave and radio frequency (RF) technologies provide advanced pasteurization solutions, ensuring food safety, extended shelf life, and superior product quality.

Traditional steam and water-based heating methods can be time-consuming and may degrade food quality. In contrast, SAIREM’s 100% electric technology delivers uniform heating, higher energy efficiency, and significantly faster processing times. This process preserves the taste, color, texture, and nutritional properties of food while eliminating the need for preservatives.

Additionally, the precise temperature control and rapid heat transfer limit bacterial growth, ensuring a safer, fresher, and more consistent final product. Our microwave solution ensures no damage to packaging during the process—no holes, no valves, and no damaged plastic film, for example.

Our food solutions in few words...

From drying and pasteurization to tempering, decontamination, disinfestation, quick cooking, heating, and extraction, SAIREM’s microwave and radio frequency solutions cover a wide range of food processing needs.

Whether using our standard equipment or developing custom-built machines tailored to specific requirements, we ensure efficiency, precision, and sustainability. With decades of expertise and a commitment to innovation, SAIREM is your trusted partner for high-performance, energy-efficient, and food-safe processing solutions.

Our product groups

Downloads

Keywords

- drying

- pasteurization

- decontamination

- extraction

- ready to meals

- pasteurisation

- tempering

- defrosting

- microwave

- radio-frequency

Our Products

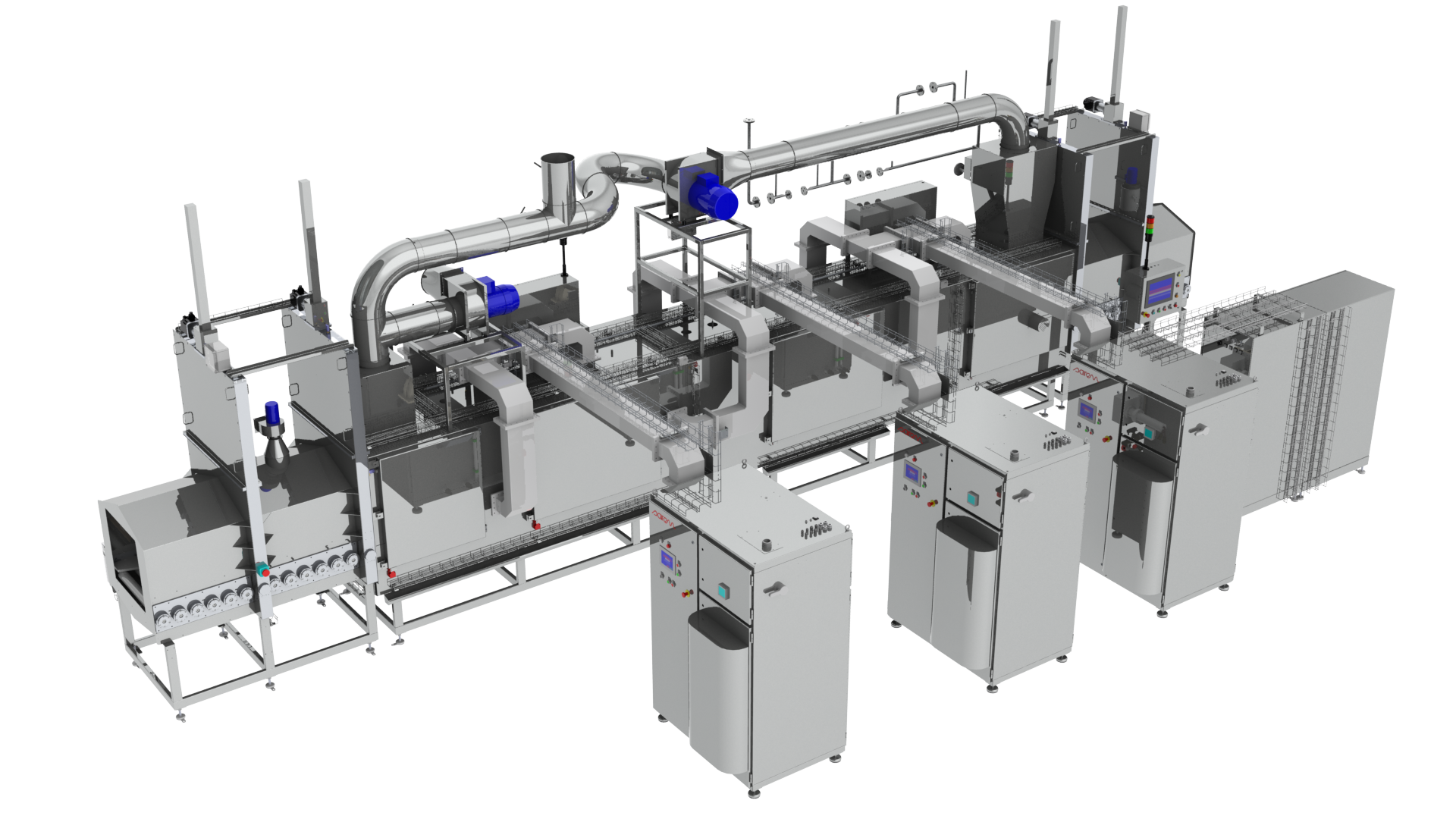

Microwave Tempering Tunnels

Microwave and RF tunnels are perfectly adapted to thaw meat and fish products. These technologies work with all kinds of meat: beef, pork, poultry… They are effective on raw or processed products (like sausages for example) without oxidation or alteration of the

product’s organoleptic properties.

- The temperature homogeneity of +/- 2 °C throughout the food block allows for better post processing of your products.

- MW and RF tempering processes allow you to heat significant quantities of products, in the form of pieces or blocks of meat and fish, with or without packaging.

- This tempering process is extremely fast: you will be able to process several tens of tons of meat products in one day versus several days with traditional processes.

- Thanks to the speed and performance of the MW and RF tempering process, bacterial development is significantly reduced. Your meat products are tempered in a totally safe way.

- Unlike classical tempering processes such as tempering chambers, microwave and RF processes significantly reduce drip loss. It’s a very profitable way to defrost your meat products.

Speed : while classical defrosting and tempering methods take hours or days to temper or defrost your food products, MW and RF technologies take from 3 to 20 minutes. In addition, there is no need to waste time unpacking your products. They can easily be tempered or defrosted in their original packaging (plastic film, cardboard, plastic box, etc).

Savings : the speed and uniformity of MW and RF processes minimize product drip losses and

degradation. By completely eliminating weight losses caused by conventional defrosting methods (which can represent up to 8% of the ingredients to be transformed) you immediately improve your raw material yield. The payback can be as short as 6 to 12 months. In addition to saving money, you also save space thanks to the small footprint of our tempering equipment. Our machines replace large tempering or defrosting rooms and eliminate the need for space to house the pallets waiting to temper slowly in the traditional way.

Safety : thanks to the rapidity of MW and RF tempering and defrosting processes, bacterial growth is limited. Defrosting food products with a traditional method can take hours or even days, increasing the health risk. On demand, and for optimal food safety, our tunnels allow you to separate incoming and outgoing product flows to avoid cross contamination. In addition, microwave and RF technologies are safe and SAIREM’s systems are fitted with sensors to prevent microwave/RF leakage

Quality : unlike some traditional methods, MW and RF tempering and defrosting preserves all the organoleptic properties of your food products: color, weight, taste, vitamins, nutriments… Moreover, the temperature homogeneity of +/- 1 °C throughout the food block allows for better post processing of your products.

Microwave Tempering Ovens

Microwave and RF ovens are perfectly adapted to thaw meat and fish products. These technologies work with all kinds of meat: beef, pork, poultry… They are effective on raw or processed products (like sausages for example) without oxidation or alteration of the

product’s organoleptic properties.

- The temperature homogeneity of +/- 2 °C throughout the food block allows for better post processing of your products.

- MW and RF tempering processes allow you to heat significant quantities of products, in the form of pieces or blocks of meat and fish, with or without packaging.

- This tempering process is extremely fast: you will be able to process several tens of tons of meat products in one day versus several days with traditional processes.

- Thanks to the speed and performance of the MW and RF tempering process, bacterial development is significantly reduced. Your meat products are tempered in a totally safe way.

- Unlike classical tempering processes such as tempering chambers, microwave and RF processes significantly reduce drip loss. It’s a very profitable way to defrost your meat products.

Speed : while classical defrosting and tempering methods take hours or days to temper or defrost your food products, MW and RF technologies take from 3 to 20 minutes. In addition, there is no need to waste time unpacking your products. They can easily be tempered or defrosted in their original packaging (plastic film, cardboard, plastic box, etc).

Savings : the speed and uniformity of MW and RF processes minimize product drip losses and

degradation. By completely eliminating weight losses caused by conventional defrosting methods (which can represent up to 8% of the ingredients to be transformed) you immediately improve your raw material yield. The payback can be as short as 6 to 12 months. In addition to saving money, you also save space thanks to the small footprint of our tempering equipment. Our machines replace large tempering or defrosting rooms and eliminate the need for space to house the pallets waiting to temper slowly in the traditional way.

Safety : thanks to the rapidity of MW and RF tempering and defrosting processes, bacterial growth is limited. Defrosting food products with a traditional method can take hours or even days, increasing the health risk. On demand, and for optimal food safety, our tunnels allow you to separate incoming and outgoing product flows to avoid cross contamination. In addition, microwave and RF technologies are safe and SAIREM’s systems are fitted with sensors to prevent microwave/RF leakage

Quality : unlike some traditional methods, MW and RF tempering and defrosting preserves all the organoleptic properties of your food products: color, weight, taste, vitamins, nutriments… Moreover, the temperature homogeneity of +/- 1 °C throughout the food block allows for better post processing of your products.

Microwave Drying Tunnels

Our equipment associates microwave or radio frequency with hot air, steam or vacuum, for excellent results in various applications such as drying herbs and plants, fruits, vegetables, cereals, insects or other food products ...

Homogeneous drying : with MW or RF drying, the process will occur at the same rate inside the product and on the surface, avoiding burnings.

Selective heating : with this process, you can dry a specific part of your product, without to damaging the final product properties or quality. Our machines are designed so that drying temperatures can be perfectly controlled.The selective drying to the core of the product is quick and homogeneous while preserving the food’s properties, as the MW and RF heat faster the water to be evaporated than the product itself.

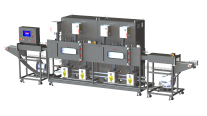

Ready-meals Microwave Pasteurisation Tunnels

Pasteurization of packaged product with microwave and radio frequency technologies is emerging as a quick, efficient and safe process.

Rapidity : MW and RF technologies are perfectly suited to achieve uniform heating are quick way to reduce microbial load at the core and the surface of the packed food product simultaneously. Unlike traditional processes, the required pasteurization level is achieved

much faster, in matter of minutes.

Quality : this process greatly reduces the risk of product degradation. Indeed, the organoleptic properties are preserved but also its freshness, even for heat-sensitive packaged food products. MW and RF are capable to garantee a fresh taste and a safe food with a shelf-life

extension.

Savings : unlike conventional pasteurization and sterilization systems, microwave and RF solutions allow significant savings in time, space and energy. They are a quick and economical heating process that transmit the energy directly to product and avoid losses into the surrounding atmosphere. All kind of packaged food products can be pasteurized and sanitized by MW and RF ready-meals, tortillas, ...