International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

SPRAY UNIT – THE SOLUTION TO PRODUCT STOPS CAUSED BY ADHESION

SPRAY UNIT – THE SOLUTION TO PRODUCT STOPS CAUSED BY ADHESION

Description

Poultry, turkey ground meat, or plant-based alternatives – many sensitive products tend to adhere to metal surfaces. This leads to inconsistent product infeed, interruptions in process flow, and increased manual effort. The consequences: hygiene risks, reduced efficiency, and compromised product quality.

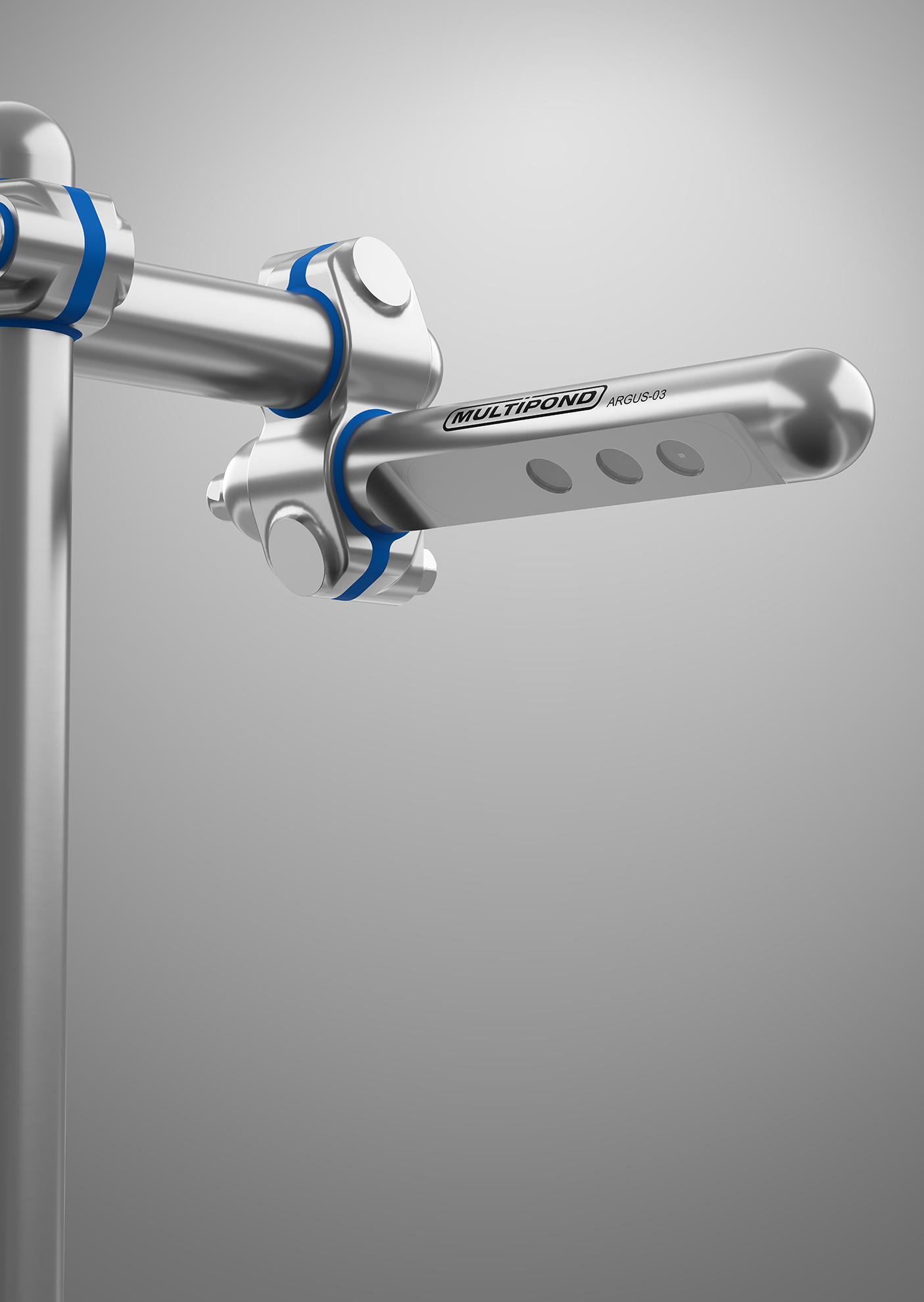

MULTIPOND offers the solution: an innovative spray unit designed to tackle exactly this issue.

The New MULTIPOND Spray Unit Solves the Problem

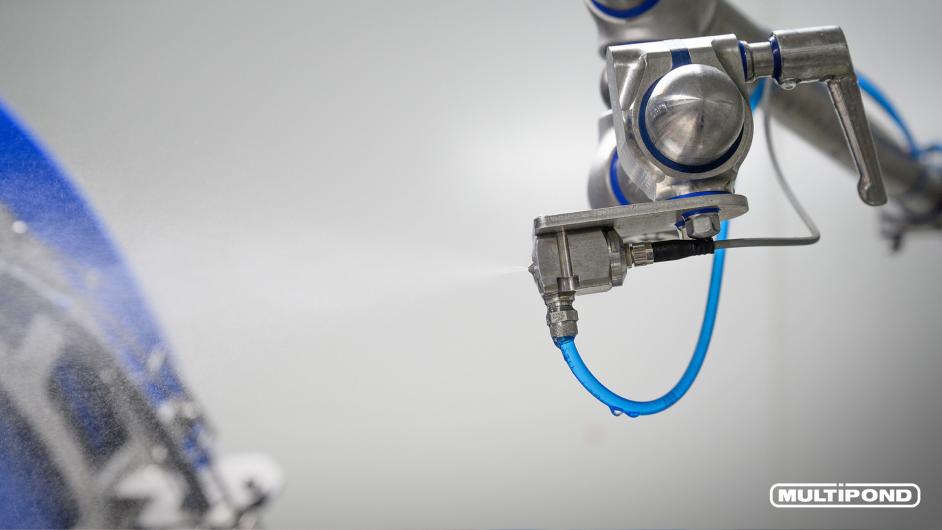

The spray unit uses electronically controlled moisture regulation to minimize static friction. The result: smooth, uninterrupted product flow – without compressed air, without contamination risk, and with low energy consumption.

Key Benefits at a Glance

Compressed-air-free spraying – hygienic, energy-efficient, and virtually maintenance-free

Built for demanding environments – IP69 design enables high-pressure and steam cleaning

Precise moisture control – ensures reliable product flow with minimal water usage

Easy retrofit – no modifications, no downtime

Weight accuracy preserved – precise dosing avoids over-moistening

Technological Features

Electronically controlled spray frequency – ensures pinpoint moisture application

Stable water pressure starting at 3 bar, optimal at 4 bar – for consistent performance

Ultrafine spray mist – tailored to product type and line speed

Hygienic construction – no residue buildup, no microbial hotspots

Retrofit Instead of Replace – The MULTIPOND Principle

The spray unit can be easily integrated into existing production lines – without structural changes. This makes it ideal for retrofit applications, adding a critical function to your line: reliable product feeding, even with sticky products. The investment pays off quickly – through less downtime, reduced waste, and more stable processes.

Your Benefits

Less manual intervention – automatic moistening increases process reliability

Lower water consumption – conserves resources and reduces operating costs

No compressed air needed – significantly cuts energy usage

Experience It Live at IFFA 2025 – Hall 12.0, Booth B10

Our specialists will show you how to protect your line against product jams with minimal effort – hygienically, efficiently, and economically.