International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

PATENTED STEPPED PROFILE FOR HANDLING STICKY PRODUCTS

PATENTED STEPPED PROFILE FOR HANDLING STICKY PRODUCTS

Description

- PATENTED SURFACE PROFILE ON PRODUCT CONTACT PARTS

- MINIMIZED PRODUCT ADHESION

- CONTROLLED FEEDING OF EXTREMELY STICKY PRODUCT

- GENTLE ON PRODUCT

- EASY TO CLEAN

- CAN BE RETROFITTED

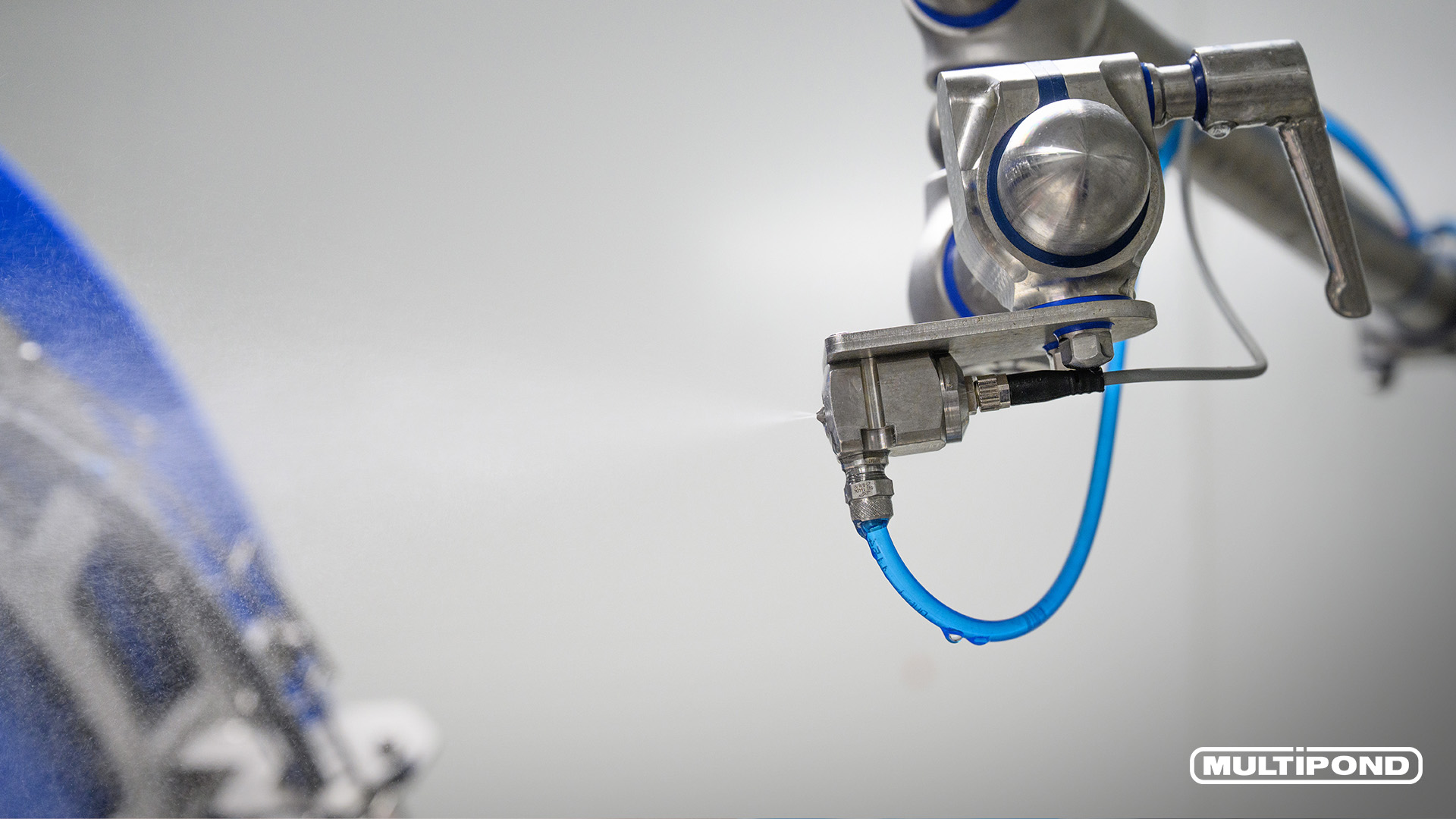

The automated handling of sticky products like fresh or marinated meat, poultry and fish is extremely challenging, which normally results in these products still being manually or semi-automatically weighed. MULTIPOND’s patented innovation offers an automation solution that is gentle on products and easy to clean.

PATENTED INNOVATION

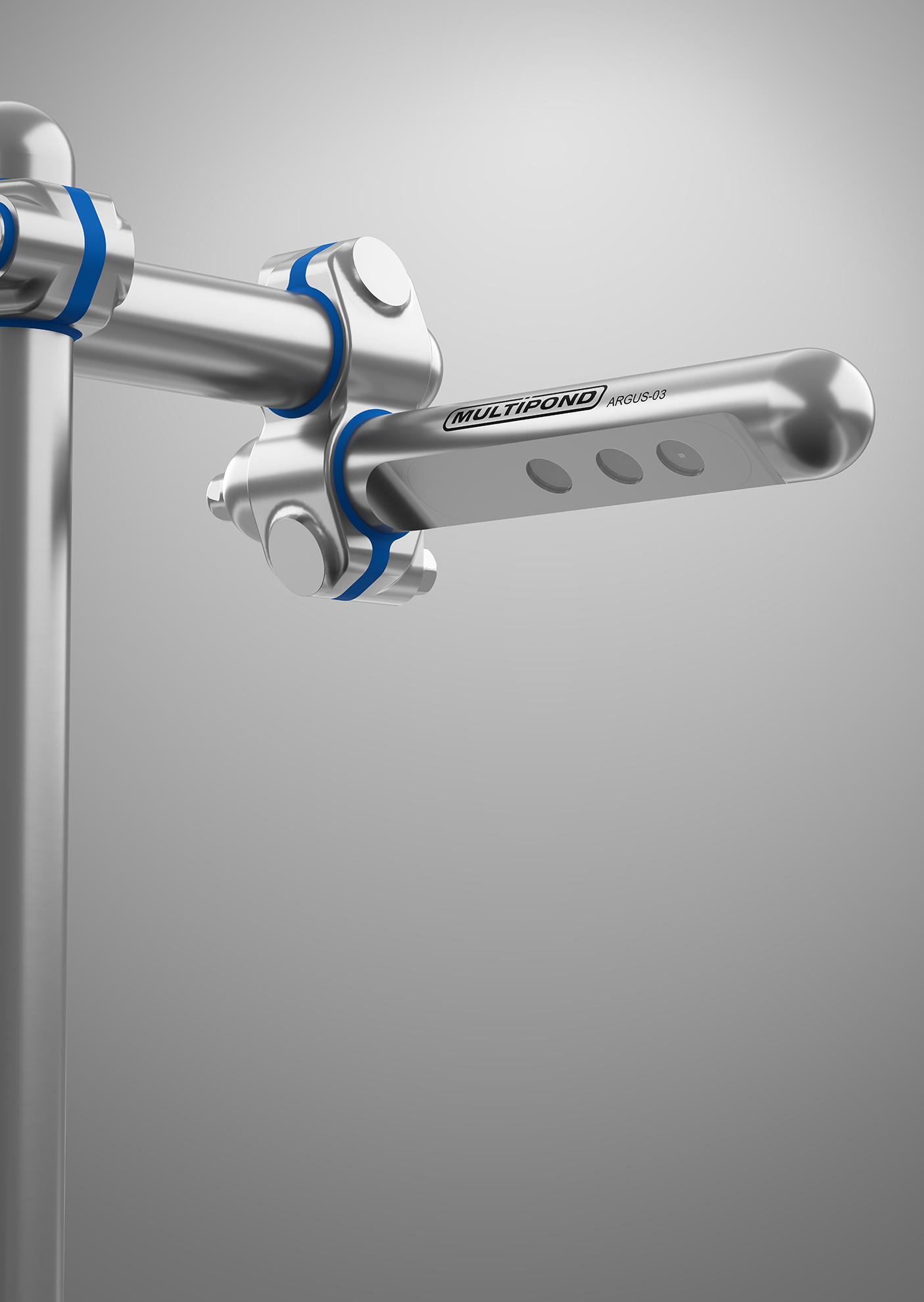

Based on a special surface profile on feed trays and the central distribution cone, the product feeding characteristics of the weigher are considerably improved and / or controlled feeding is now possible even with difficult product. The stepped profile minimizes the contact surface between the product and the cone and / or the feed tray surface, which leads to lower product adhesion. Consequently, this “simple” yet extremely effective solution does not require additional equipment to control the feeding of such products, like a screw conveyor and such. The product is not exposed to any additional mechanical processes, just the usual vibration from the feed trays. The major advantage of this surface technology has already been successfully proven in production for weighing poultry, meat, fish, surimi and various convenience food components.

EASY TO CLEAN AND MAINTENANCE

Due to the fact that there is no need for any additional equipment, the solution is equally suitable for the strict hygiene requirements in the food industry. Both, the distribution cone as well as the feed trays, follow the design and accessibility of a standard MULTIPOND multihead weigher and are only equipped with a patented surface structure. All product contact parts can still be removed quickly and easily for cleaning, product change and maintenance.