Production diversity, hygiene pressure, and efficiency demands – the requirements for food producers are steadily increasing.

The new SAL system from MULTIPOND offers a future-ready solution for companies looking to combine precise weighing processes with maximum hygiene and flexibility.

Whether for conventional meat products or alternative proteins, for mid-sized operations or high-performance facilities – the SAL is modular, scalable, and precisely tailored to evolving production requirements.

What does SAL stand for?

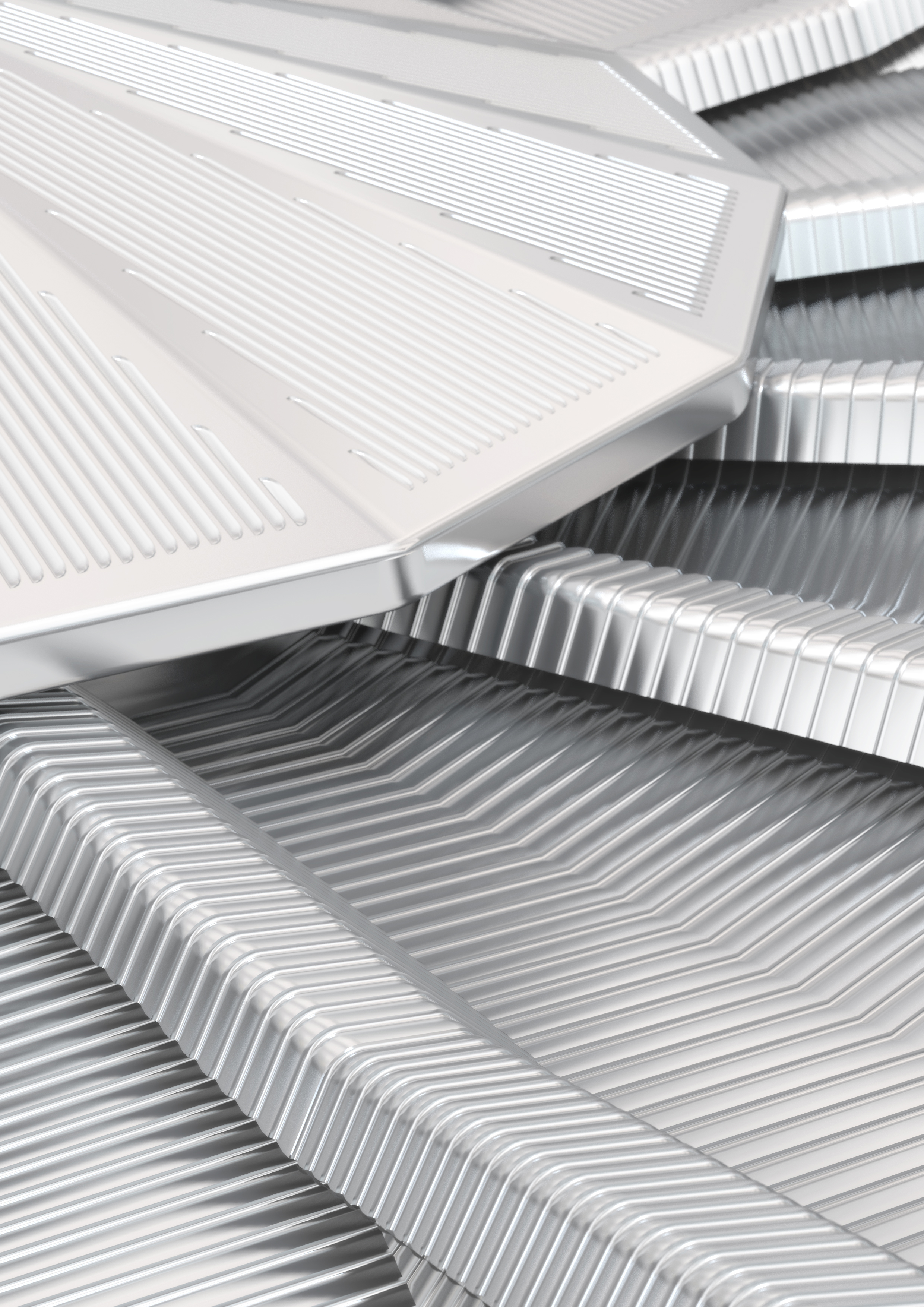

Semi-Automatic Linear System – a combination weighing system that merges automated precision with manual handling, setting new standards in cleaning, product changeovers, and line integration.

Key Highlights at a Glance

Up to 60 cycles per minute – even with demanding products

Tool-free container change – for fast product changeovers

Low-drop transfer unit – minimizes mechanical stress and material loss

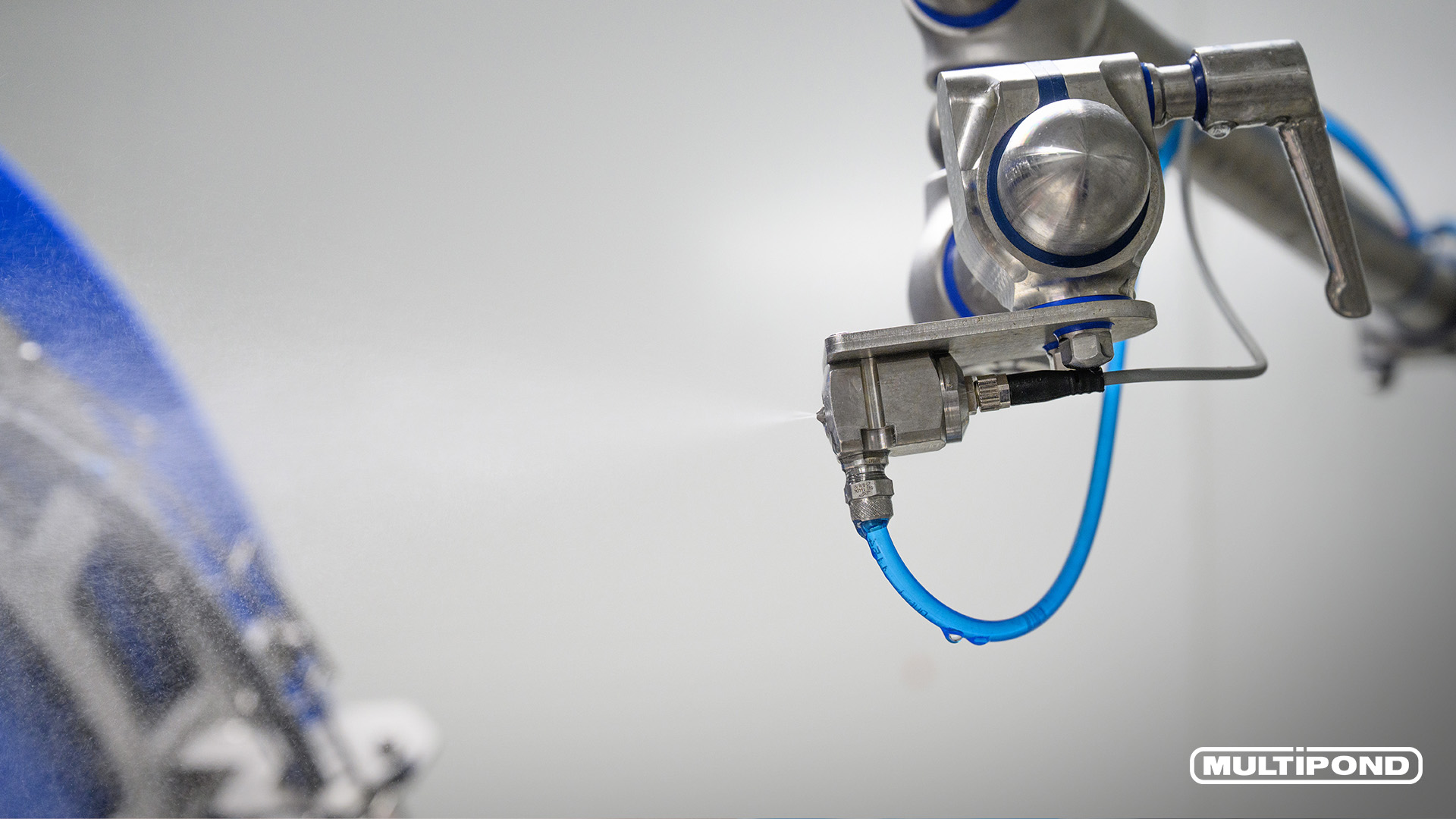

IP69 hygienic design – suitable for high-pressure/steam wet cleaning

EHEDG & USDA compliant – meets international hygiene standards

Digital interfaces – seamless integration with line control systems

Practical Advantages

Production managers drastically reduce changeover times and keep processes stable

Quality managers benefit from reliable accuracy and hygiene monitoring

Purchasing departments invest in durable technology with fast return on investment

Startups and SMEs gain a scalable solution for growth phases

Large-scale producers flexibly cover production peaks with confidence

Application Versatility & Integration

Thanks to its modular design, the SAL can be integrated into a wide range of production lines – from traditional butcher lines to vegan protein production. It is also ideal as a backup system during maintenance of automated lines or for partial automation of existing processes.

Automation Meets User-Friendliness

Automatic calibration ensures consistent measuring accuracy even during frequent product changes. At the same time, the flexible container system allows tool-free exchange – quick, intuitive, and safe.

Sustainability & Efficiency

Less cleaning effort, less downtime, less waste – the SAL saves time, resources, and operating costs. Well-engineered in Germany.

Experience it live at IFFA 2025 – Hall 12.0, Booth B10

Our experts will show you how the SAL enables an efficient, hygienic, and scalable weighing solution.