International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

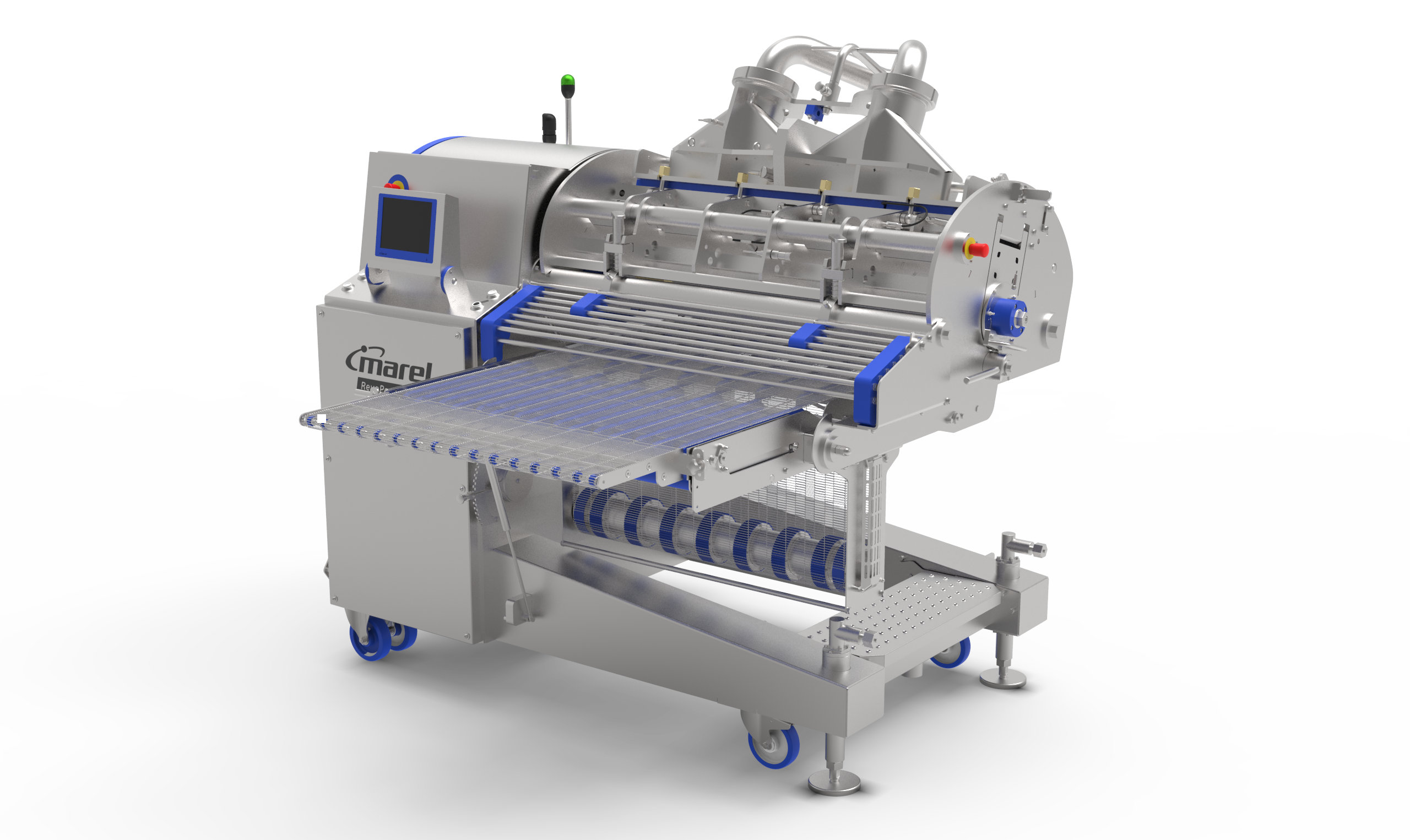

FALCON evolution + preformer

Description

The TREIF FALCON evolution provides processors with the flexibility to cut bone-in and boneless red meat, poultry, pork and cheese at high speeds and high throughput for yield-optimized portioning.

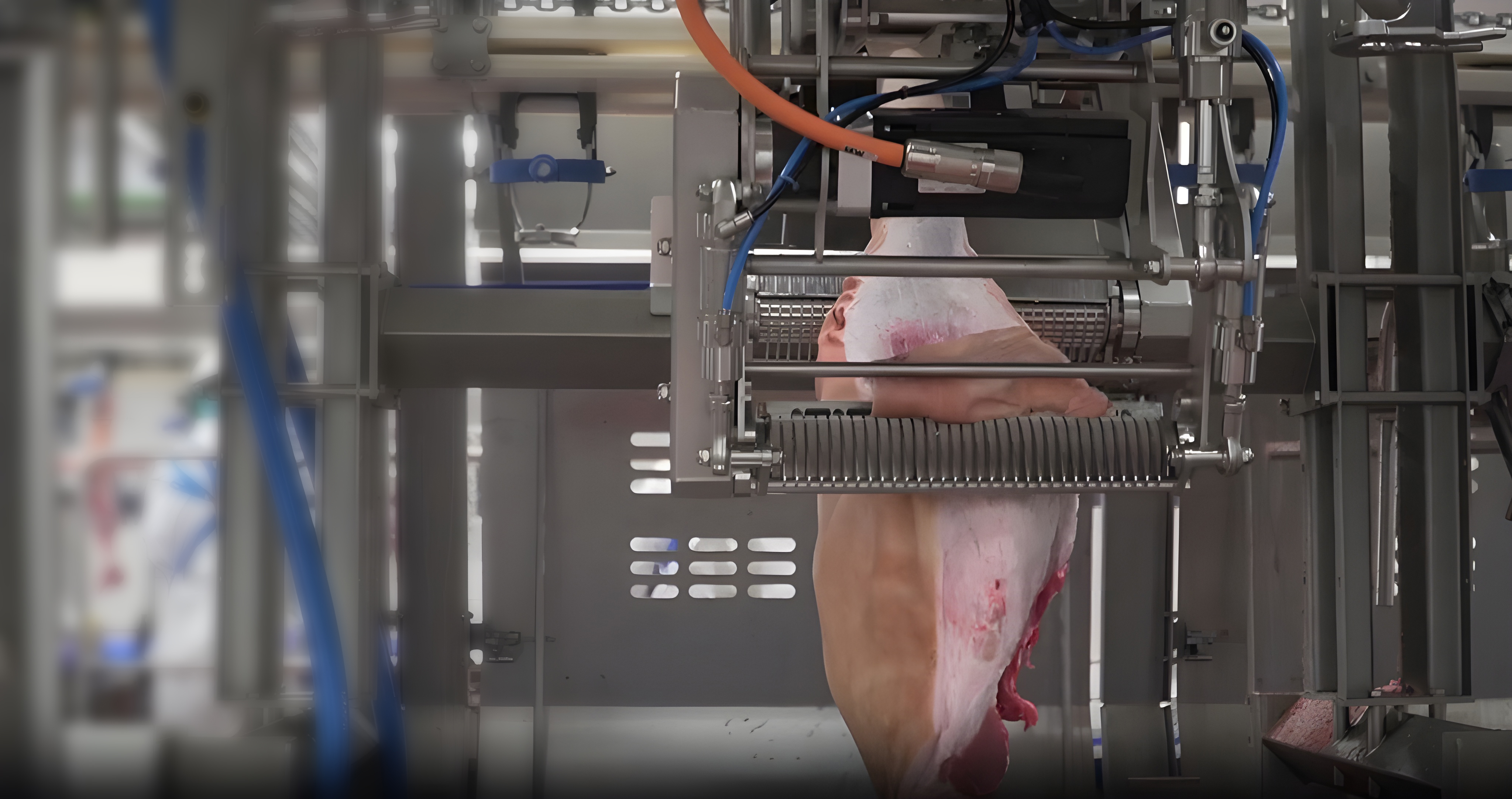

Raw material is accurately scanned for size, shape, and weight by cameras from four sides and an inbuilt scale. Cuts are automatically calibrated to meet the required weight or thickness. A gripper and down-holder stabilize raw material and ensure blades are guided along product contours for incredible cutting accuracy.

Adding the TREIF FALCON preformer to the evolution makes end-product appearance consistent, helping to improve the market value and brand position. The preformer brings raw material into a natural shape before cutting, producing high-quality end-products of uniform thickness. Optimizing yield from the first to the last cut.

The TREIF FALCON evolution or evolution preformer seamlessly integrates into processing lines reducing reliance on manual labor through increased automation.