International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Description

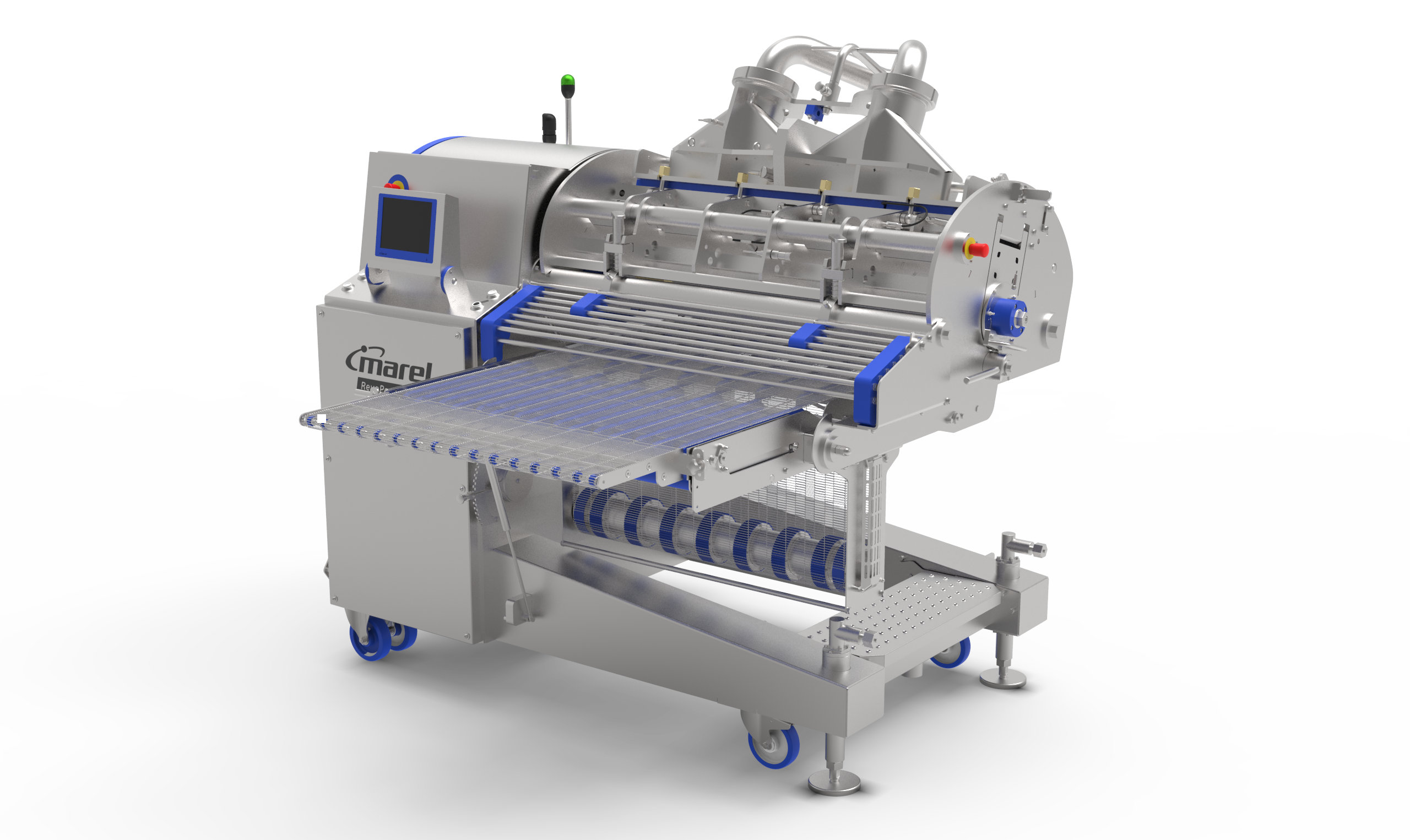

Leaf lard removal (flare fat removal) is one of the “toughest” processes in the slaughtering of pigs. The process is physically demanding to do manually and complicated to do with hand-tools. With Marel's new M-Line Leaf Lard Remover (MLR), it is now possible to do the job precisely, efficiently and without damaging the carcass surface.

The M-Line Leaf Lard Remover (MLR) eliminates the steps of manual processing and the need for any pre-cutting. There is no need for manual scarfing or scraping of the lard tip end, neither a need to protect the diaphragm from being damaged. Even kidney offal may remain inside the carcass while leaf lard pulling, if the customer’s process requires so.

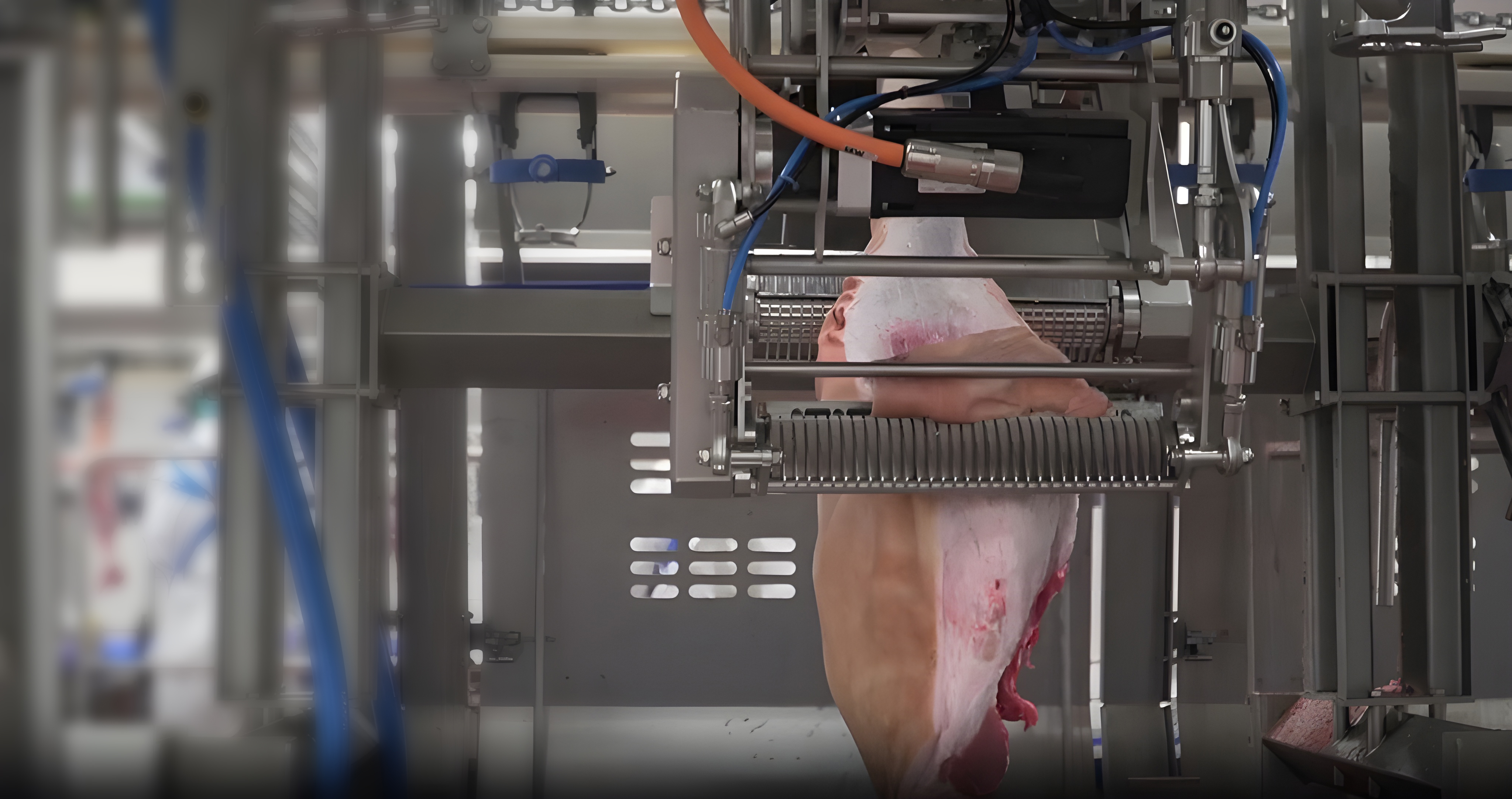

The system bases the pulling process through accurate 3D scanning of the inner belly of each half carcass.

Two independent robots work together on each carcass, respectively pulling the left and right sides of the leaf lard off the carcass.

The M-Line Leaf Lard Remover is a hanging version of the robot installation. The hanging version simplifies hygiene and increases floor space, which can instead be used for Dolavs or logistics conveyors.

The M-Line Leaf Lard Remover has a capacity of 650 carcasses per hour.