International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

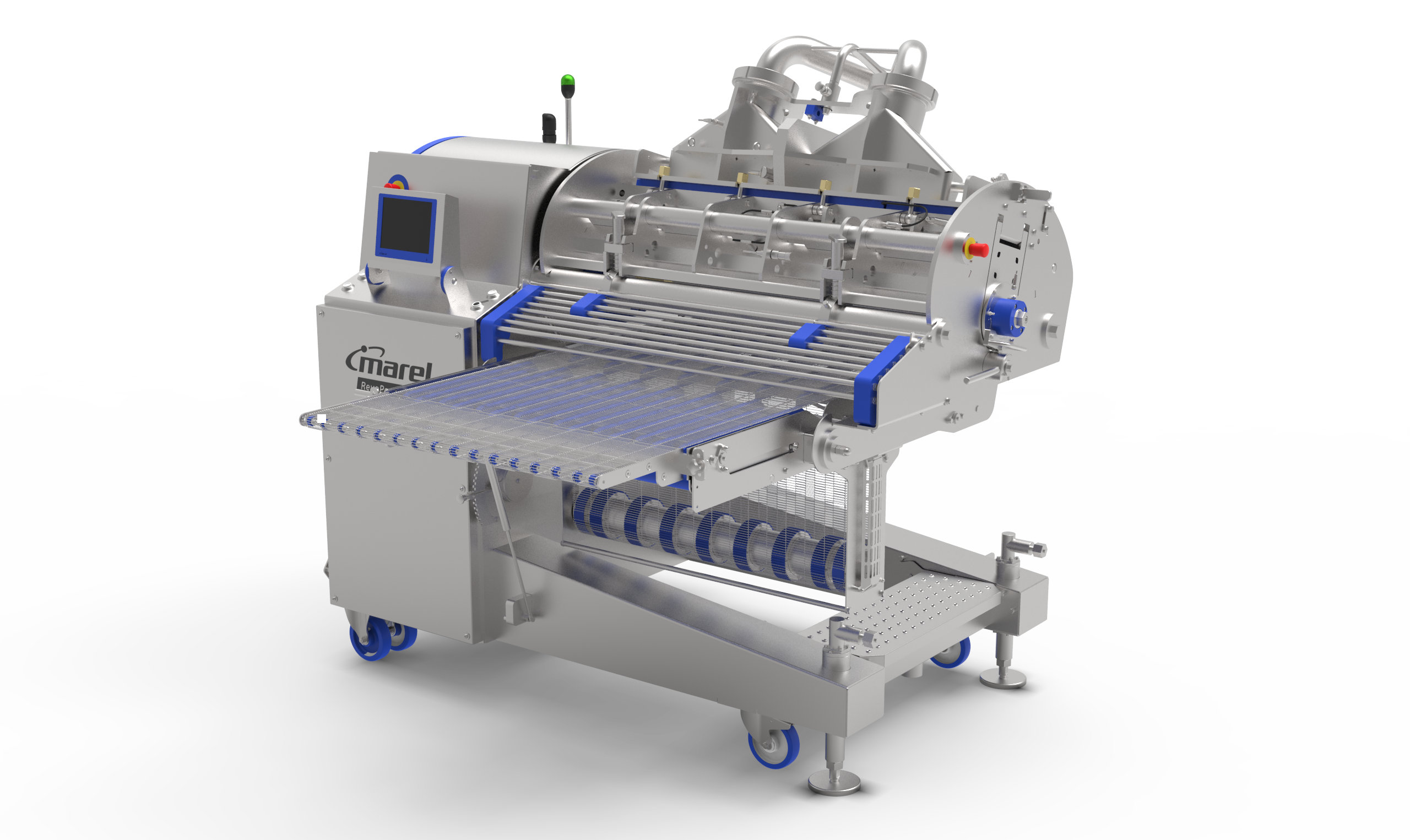

DeboFlex – Primal Cut, Fore-end and Hind-leg

DeboFlex – Primal Cut, Fore-end and Hind-leg

Description

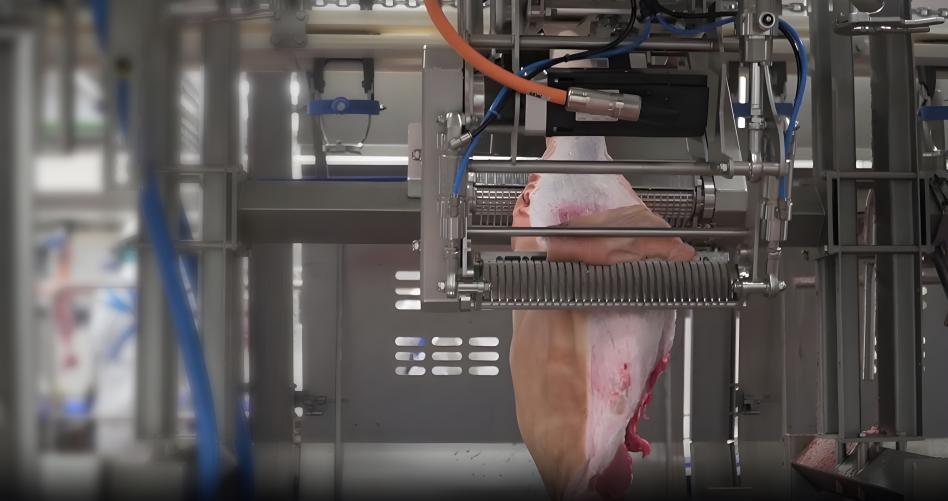

The DeboFlex is a modular and flexible platform that revolutionizes pork cutting and deboning through the innovative technique of vertically hanging primals. Designed to enhance the efficiency, sustainability and profitability of your processing line, the DeboFlex expands the range of pork products you can produce, resulting in a more agile business.

The revolutionary platform seamlessly harmonizes automation with ergonomically designed workstations, creating a safe and comfortable environment for your operators. By automating and simplifying critical aspects of the processing workflow, the DeboFlex enhances yield, throughput, and product quality while decreasing your dependence on labor.

Benefits of hanging pork cutting and deboning include:

- Increased operator "knife in meat" time

- Wider product variety

- Optimized raw material

- Improved shelf life

- Deskilled tasks and no heavy lifting

DeboFlex streamlines operations, automating tasks for quicker and more precise results, ensuring a consistently high-quality product. Along the DeboFlex platform, product-to-product contact is virtually eliminated, significantly reducing cross contamination through hand to product contact.