International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Röntgenscanner

Description

Die Röntgenprüfung ist bei Herstellern, die die strengen Verfahrensregeln des Einzelhandels einhalten und für die Produkte ihrer Marke größtmöglichen Schutz wünschen, mittlerweile die bevorzugte Detektionsmethode. Unsere Entwickler arbeiten nach dem Leitsatz von LOMA® Designed to Survive®. Dabei achten sie auf die Einhaltung unserer zentralen Werte:

SICHER – Produktsicherheit für Endverbraucher und Betriebssicherheit im Einsatz

LANGLEBIG – Stabile, robuste, zuverlässige Systeme speziell für die Lebensmittelproduktion

FLEXIBEL – Dank zahlreicher Prüfalgorithmen sowie der speziellen „Adaptive Array“-Technologie (AAT) für unterschiedlichste Prüfanforderungen geeignet

BENUTZERFREUNDLICH – Einfach im Betrieb, produktions- und umweltfreundlich, niedrige Gesamtkosten

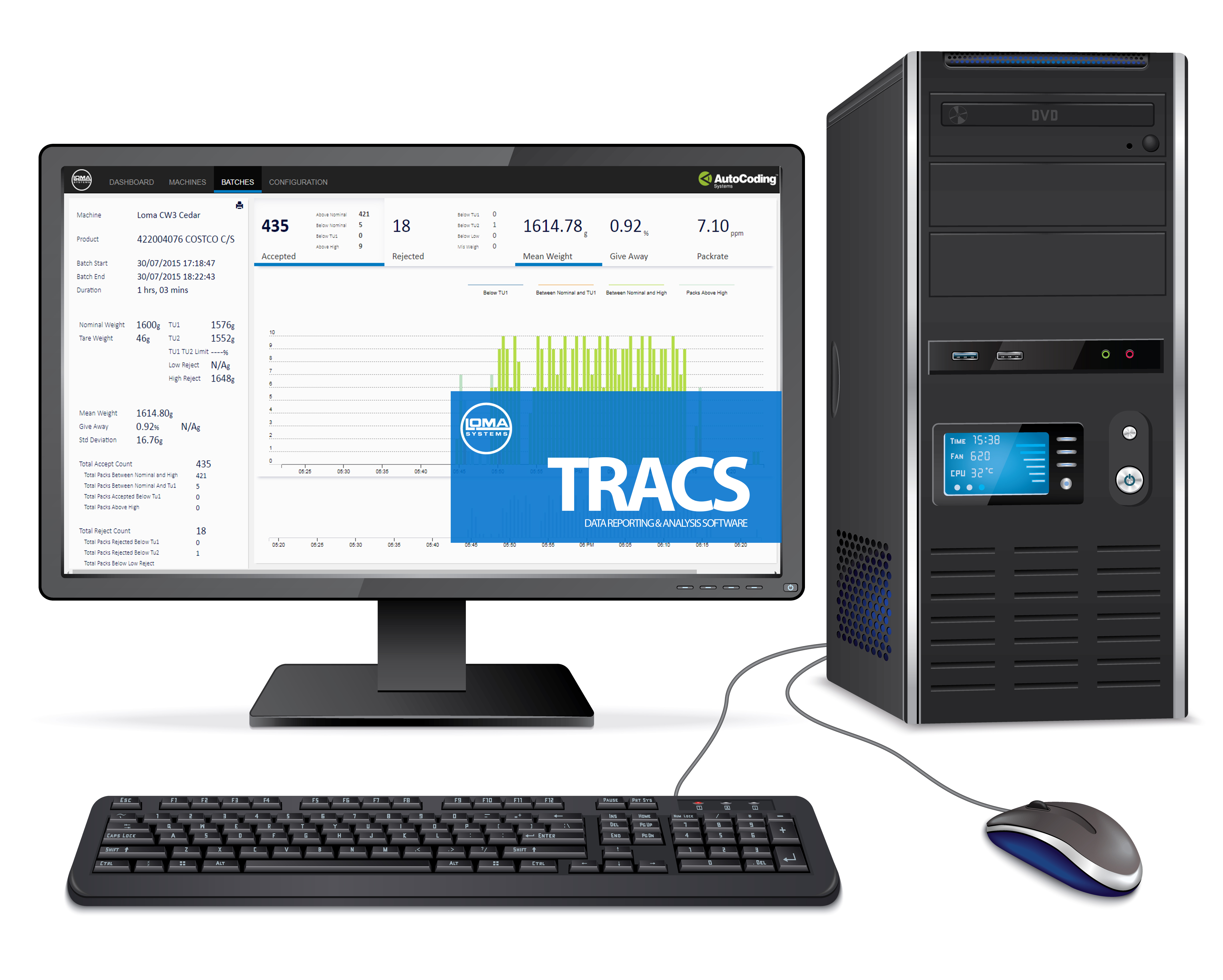

Seit fast 20 Jahren entwickelt LOMA SYSTEMS® Röntgentechnologien für die Untersuchung von Lebens- und Arzneimitteln. Dank zahlreicher Anlagen in aller Welt sowohl für große als auch kleine Herstellerfirmen verfügen wir über sehr viel Erfahrung im Röntgenbereich. Inzwischen ist mit der Serie X5 die fünfte Generation unserer Röntgenscannersysteme auf dem Markt.

Röntgenscannersysteme bieten viele Vorteile:

Erkennung unterschiedlichster Verunreinigungen

- Hervorragende Detektion von Verunreinigungen durch Eisenmetalle, Nichteisenmetalle und Edelstähle

- Zuverlässige Detektion von Glas, Knochen, Keramik/Steinen, dichten Kunststoffen und Produktklumpen sowie von anderen Fremdkörpern anhand der relativen Dichte der Verunreinigungen

Zuverlässige Prüfung von Produkten in Aluschalen oder Metallfolien

- Detektion von Edelstahl und Nichteisenmetallen in Lebensmitteln, die in Metallfolie oder Aluschalen verpackt sind, ohne dass die Verpackung die Detektion beeinträchtigt

Integritätsprüfung der gescannten Produkte

- Röntgenscannersysteme können gleichzeitig die Produktintegrität prüfen, z. B. fehlende Komponenten, überschüssige Produkte (nach Volumen oder Stückzahl) und Kontrollwiegung

- X5C Kompakt Röntgenscanner

- X5 Spacesaver Röntgeninspektionsystem

- X5 Pack Röntgenscanner

- X5 Pipeline Röntgenscanner

- Bulkflow Röntgenscanner Kontrollsystem

- X5 XL800 Röntgeninspektionsystem

- X5 Spacesaver/CW3 Kontrolle & und Scan Kombinationssystem

Address

LOMA SYSTEMS

Summit Avenue

Farnborough, Hampshire

GU14 0NY

Grossbritannien und Nordirland

Telephone+44 1252 893300