International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

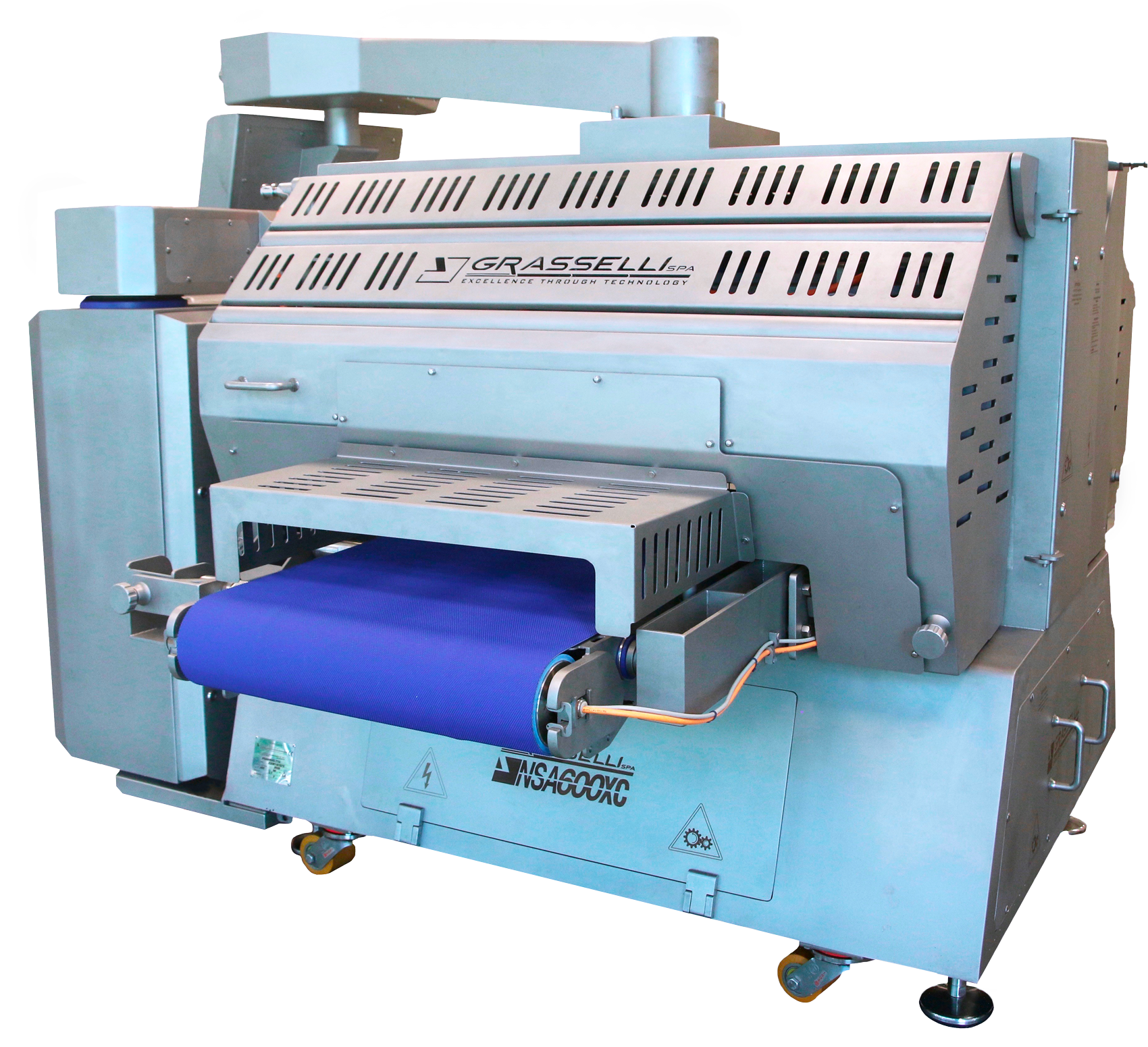

KSL CBU 3B - Horizontal poultry slicer for cutting and separating perfectly even slices of boneless meat, thanks to the Grasselli multi-blade cutting system.

KSL CBU 3B - Horizontal poultry slicer for cutting and separating perfectly even slices of boneless meat, thanks to the Grasselli multi-blade cutting system.

Description

The KSL CBU 3B cuts products with unparalleled precision, automatically separates the slices into three groups and deviates them on three different outfeed belts. Maximum efficiency and extreme flexibility.

1.Chicken breast unit for optimized processing

KSL CBU 3B is able to cut fresh or cooked, positive temperature products in perfectly parallel slices thanks to the Grasselli multi-blade cutting system, while allowing to separate the slices on three different outfeed conveyor belts according to the desired quantities.

2. Flexible solution

The product can either be cut in two or three slices keeping all of the product on the lower outfeed conveyor belt, or in several slices placing the desired number of slices on the lower conveyor belt, the desired number of slices on the middle outfeed conveyor belt while removing the last out-of-spec slice and placing it on the upper outfeed conveyor belt. Many different configurations are available depending on the next processing step.

3. Perfect in-line solution

In combination with the high productivity slicers NSA and NSA XC, a completely automated line can be obtained for the production of high quality strips or dices with a high throughput.

4. Optimized downstream process

The additional AL3 conveyor belt enables the slices to be placed on the lower outfeed conveyor belt and on the middle conveyor belt at the same level and in the same direction as the product feed in line.

5. A variety of options for the highest performance

With a working width of 350 mm, KSL CBU 3B can be equipped with conveyor belts with differentiated grip to better suit the product infeed process.

2. Double insulated protection circuit

No low voltage electricity passing through the operator’s body.

3. User-Friendly System

Thanks to the display, the operator can verify the correct functioning of the system or check for alarms when the machine is operating or is in stand-by mode.

4. Durable and carelessness-proof

The connection wires are fitted with magnetic plugs to avoid cable breakage.

5. Safe, whatever the working conditions

No issues of system functionality connected to humidity and wet working environments.

6. Patent-protected know how

Grasselli stands uniquely positioned as the only company with a thirty-five-year-old experience in providing unparalleled patented safety systems to allow for accident-free skinning and derinding.