International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

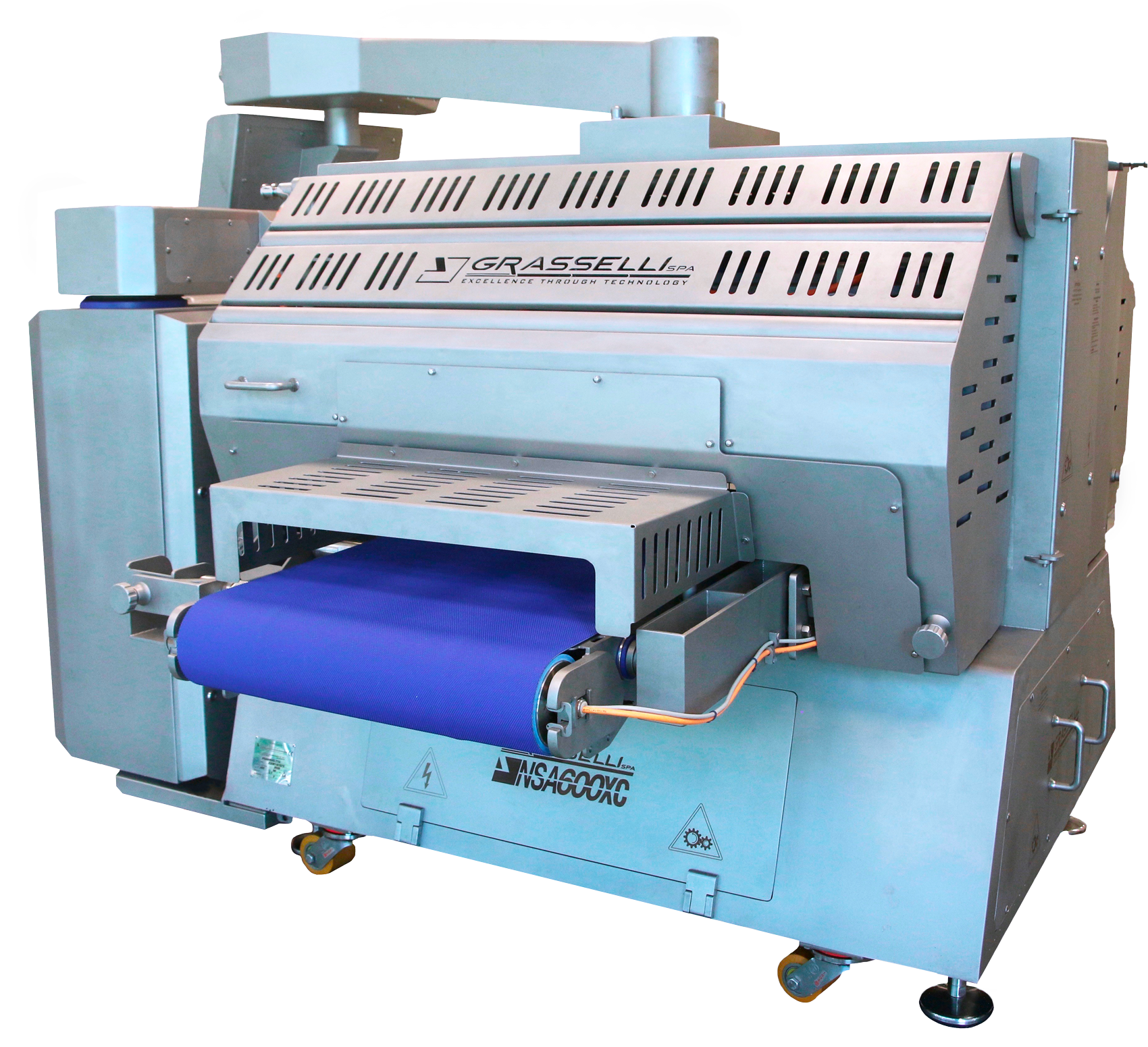

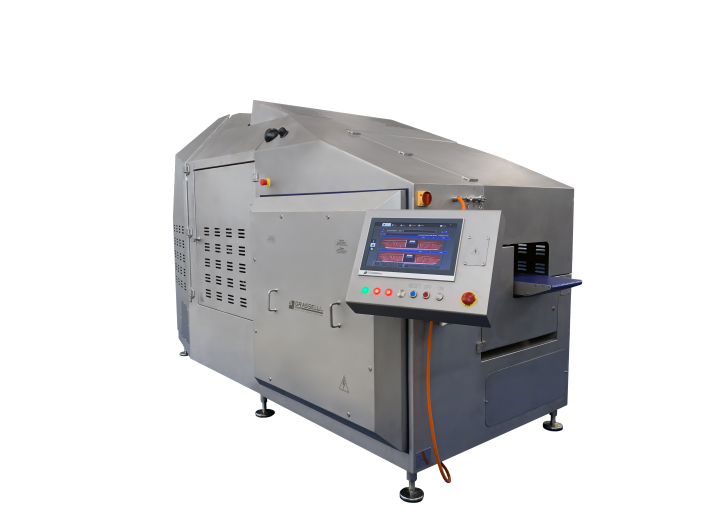

PCS - Schneidmaschine für knochenfreies Frischfleisch, ideal für das Schneiden von einzelnen Scheiben mit festem Gewicht.

PCS - Schneidmaschine für knochenfreies Frischfleisch, ideal für das Schneiden von einzelnen Scheiben mit festem Gewicht.

Description

Designed to deliver perfect slices either on weight or on thickness, according to the recipe settings

1. High yield portion slicing, both on weight and on thickness

PCS is able to slice fresh, positive temperature products or crust frozen ones (up to a 2 mm crust ). Thanks to the additional capability to divide the product in different sections with customized slicing parameters, the result is optimized in a very flexible way even when dealing withirregularly shaped products.

2. Extreme precision in delivering the target result

Through its 3D scanner system, PCS checks and analyses all the product dimensions, adjusting the slicing process to deliver the desired target.

3. Waste optimization

Thanks to the smart software, PCS can process the incoming product, calculating the weight of the final slice and automatically redistributing the exceeding weight onto the other slices according to the recipe settings in order to minimize waste.

4. The first step to a Fully Automatic Slicing Line for Trays on weight and/or thickness

In Line with our ATF - Automatic Tray Filling machine - PCS allows for high yield slicing of weight/thickness-controlled portions ready to be automatically positioned into trays.