International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

EBSmoke AG

Compact Controller EB1s

Explore product

Compact Controller EB1s

Explore product

Compact Controller EB1s

Explore productAbout us

EBSmoke AG manufactures controllers for meat processing and ionization for meat smoking. We have been building controls and developing innovations since 1985, our technologies are of Swiss quality and are in use thousands of times worldwide.

Our modern EB1 controller has a large, bright display, is easy to operate and compatible with all common brands of equipment. During operation, it is immediately clear which process step is running and how far the recipe has progressed. Programs can be adapted quickly and easily.

IFFA novelty: The EB1s controler is the little sister of the EB1 and is ideal for tumblers, autoclaves, cooking systems, boiling pans, showers, etc. Exclusively at IFFA, we are presenting our latest development for the first time.

Ionsmoke is a worldwide unique smoking process using ionisation in which the smoking time can be halved and 98% of the fine dust in the chamber is used up. This saves energy and smoking material and increases the capacity of the smoking system.

HACCP conformity is ensured by the EBLuft software, which is linked to the controls and records and visualizes all processes in the systems.

- Installation of controls and ionization on systems of all existing brands

- Reduction in energy costs, reduction in treatment time

- Process monitoring and data logging

- Personal identification

- Error forwarding via e-mail and SMS

- 24-month guarantee

- References worldwide

Our product groups

Downloads

Documents

Keywords

- Ionsmoke

- Retrofit

- Ionisierung

- Räuchern

- Steuerungen

Our Products

EBCloud Platform for Controller Management

The EBCloud platform is a market innovation: it allows you to manage and update controllers from the cloud. You have an overview of all installations and can conveniently update software and program steps of controllers via the cloud - without programming knowledge, with just a few clicks on an understandable user interface in the familiar layout.

- Dashboard with overview: All installed controllers are visible on the dashboard. Names of the controllers, in which facility a specific controller is installed, date of entry - all information is available at a glance. You can quickly switch to other facilities and see all their controllers. Choose between the tile or the list view, between the light or the nowadays very popular dark mode.

- Programming in the familiar layout: Having chosen a particular controller, relays & program steps can be customized with an easy to use "click & play" editor. Define the name and type of the relays and configure that individual process step. The editor comes in the familiar matrix design, so it is immediately understandable and easy to use.

- Reduction of effort and complexity: What previously could only be done by traveling to the customer and being present on site can now be handled via a modern cloud platform. This no longer requires in-depth technical know-how, but all settings can be made in the easy-to-use editor even by people without programming skills.

The platform is deployed from a secure and high-performance cloud environment.

Come by our booth and get a live demonstration of the EBCloud.

Compact Controller EB1s

With the EB1s, we introduce a new, compact controller for meat processing—ideal for tumblers, autoclaves, cooking systems, kettles, and showers. It is compatible with all major manufacturers and can be quickly integrated into virtually any system or machine. Ideal for replacing old and broken controllers. Together with the EBLuft Software, the controller logs all your processes which is great for HACCP compatibility.

Compact Design, Intuitive Operation

The EB1s is slightly smaller than an A5 sheet and features a bright, well-organized touchscreen that remains easy to operate—even when wearing gloves. Its self-explanatory user interface ensures quick onboarding and intuitive daily use, even for personnel with varying skill levels.

Technical & Functional Highlights

✔ Fully and freely programmable to match specific systems and recipes

✔ HACCP compatibility through network data logging

✔ 8 relays, 4 optocouplers, 8 sensor inputs for versatile control options

✔ Developed and manufactured in Switzerland for top quality

✔ Robust and adaptable for a wide range of applications

EB1 Controller

EB1 controller - latest generation control system

- The EB1 can be retrofitted to all system brands

- Especially for Ionsmoke: Live smoke density display

- Network connection for data acquisition

- Retrofitting within 1.5 days

Modern & simple design

A large, bright and easy to read screen with four buttons below, that's it.

Simple and intuitive operation

The control is as simple as your own cell phone. It is immediately understandable and applicable.

Complete process technology

Set programs, smoke quantity, times, core temperature, etc by yourself. 99 programs with 99 steps each. Or we help with the recipe creation.

In 1.5 days we change the controller on your existing system - no matter which brand, no matter which age. Retrofittable for cold, warm and hot smoke systems, universal systems, smoke and cooking systems, air conditioning and climate control smoke systems, ripening systems, cooking chambers and pasteurizers.

Food technology controls built for years of use. Store recipes individually and control programs by core temperature or F-value. With data logging and management, configure controls from the comfort of your computer. The control is optimized for a wide variety of equipment. We have controls for tumblers and autoclaves and much more. Read for yourself.

In case of power interruption the current data is stored. After switching on the voltage again, the device continues to work in the interrupted program. Further monitoring criteria are: Operating temperature, humidity and core temperature sensors. In the background, we continuously check the program contents by means of cross sum checks. In this way, we always guarantee the same products. Whether hot smoke plants, cooking plants, baking plants, intensive cooling plants, climatic smoke plants or climatic storage rooms. The control system can be installed anywhere. Either directly in a new plant or when retrofitting.

- As a control for new systems

- As a retrofit kit for existing smoke houses

- Hot smoke and cooking plants

- Baking plants

- Intensive cooling plants

- Air-conditioning smoke systems

- Air-conditioned storage rooms

Test installation for 3 months on site possible according to separate offer. Besides the installation we configure the control system with you. We optimize existing programs and can avoid unnecessary weight loss with new functions. In addition, we save energy for your operation. We always put the quality of the product first. Our control system is in use worldwide on almost all plants available on the market. Switzerland, Germany, Austria, Hungary, Slovenia, Russia, Sweden, Finland, Netherlands, Belgium, France, Spain, Croatia, China, Taiwan, USA, Canada, Alaska, Japan and Australia. The control system is extremely easy to operate thanks to dialog guidance.

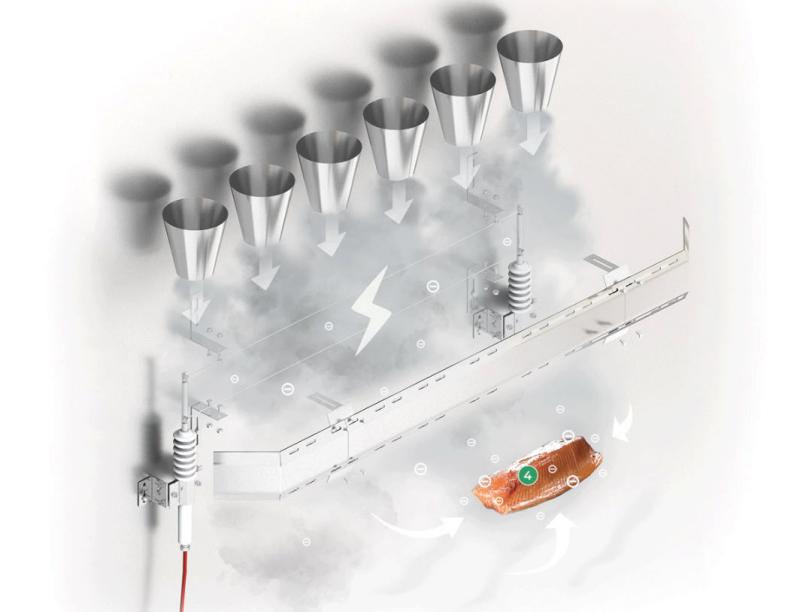

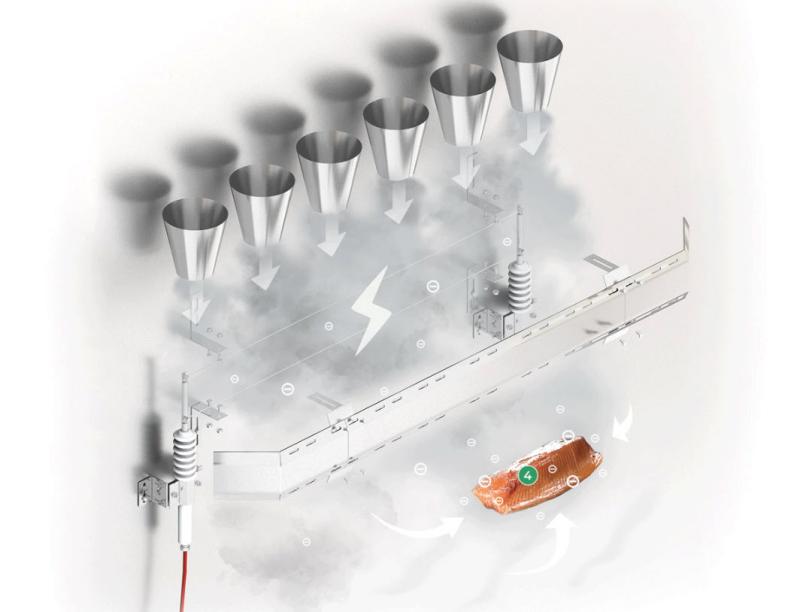

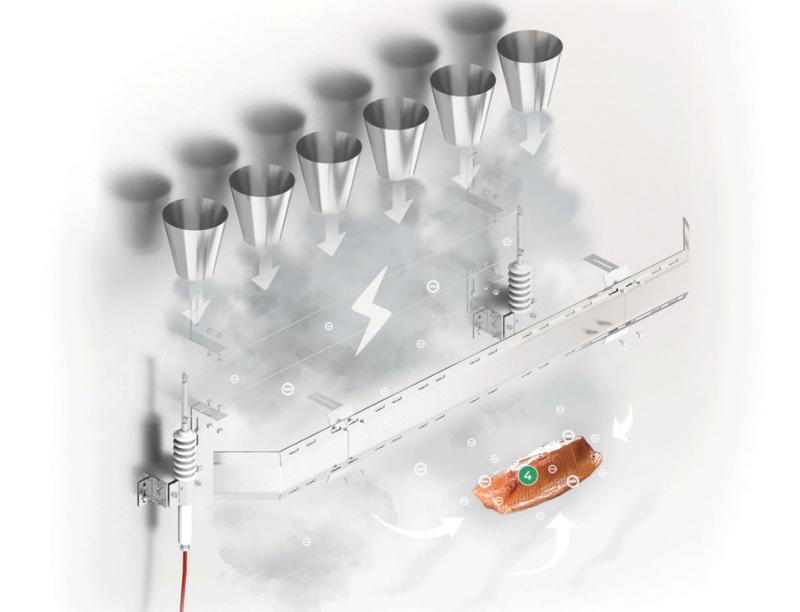

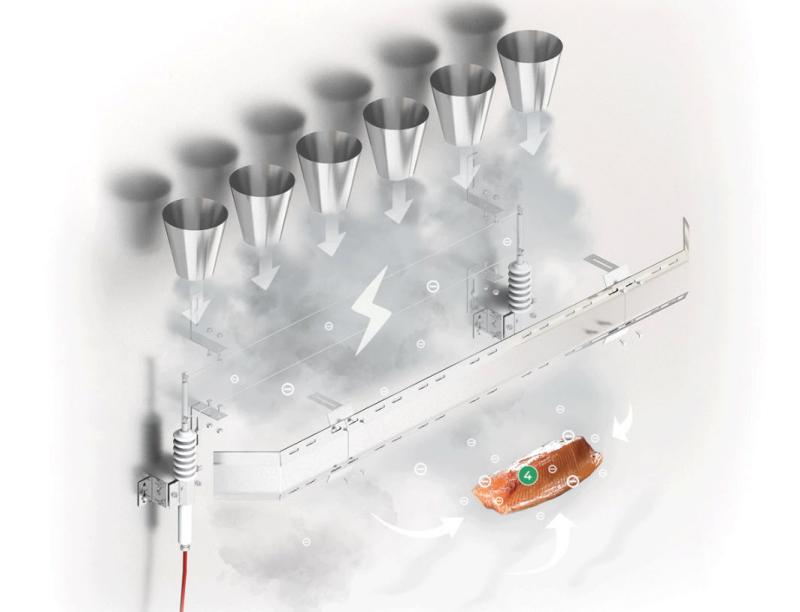

Ionsmoke - smoking with ionization

Ionsmoke - smoking without fine dust emmissions, fast and energy efficient

- Time - up to 70% faster smoking-steps

- Yield - up to 4% more yield

- Emissions - reducing 98% of fine dust emissions

- Energy - faster process times and less energy

- Quality - keeping track of smoke density for consitend quality

- Retrofit - existing smoke houses can be retrofitted

We want to preserve the tradition of smoking – and do justice to environmental and climate protection. This is why we have further developed the millennia-old process.

Adding Ionsmoke in your smoking chamber saves you energy, time and eliminates fine dust at the same time. This results in more yield. Ionsmoke controls the smoke density so that products always have the same quality.

Ionisation can save up to 70% on your smoking-time.

Ionsmoke works with high voltage electrodes that ionize the smoke particles in the air. The electrostatic forces then pull these towards the product, like magnetic forces. With this physical process we accelerate the smoking process significantly.

We have reduced the smoking time of bacon from two hours to twenty minutes with the use of Ionsmoke.

Better yields with Ionsmoke.

Usually we experience a weight loss when smoking products with natural smoke. A product may have already reached the inspected weight loss before the color is right. That results in lower product margins. With Ionsmoke the weight loss can be controlled and kept as low as possible. In addition, with less processing time the product appears to becomes more natural.

One of our customers filled his sausage casings with 155g sausage meat so that he can guarantee a weight of 140g. With Ionsmoke the customer now fills his sausage casings with 152g to get the same final weight.

Energy Savings

Ionsmoke needs typically only 2W. The heating capacity of a small system starts at 30,000W. The amount of time a product is kept in a smoking step directly correlates with the electrical bill.

Ionsmoke not only saves energy, but also reduces the burden on the Smoke-Generator resulting in longevity.

No Fine Dust Particles

The initial idea came from Ernst Goldener. He wanted to filter the smoke before it was released into the environment, in order to relieve his neighbours. Instead of ionizing the smoke in the chimney, he tried to do it directly in the chamber. After some initial successes, EBSmoke with Bruno Eigenmann entered the picture. With great knowledge about the treatment and smoking of food they created Ionsmoke.

The result: Economical smoking, with measurable 98% less particulate emissions while passing the products lab test better than conventional smoking.

Retrofittable

The modules fit on any vertically ventilated smoke system and are seamlessly connected to the specially developed control system. Smoking conventionally remains possible, if desired. Ionsmoke can be retrofitted on any system.

We help you customize your recipes for Ionsmoke. The module is water- and steam-proof and is extremely durable and resistant to every usual cleaning of a smoke house.

Measuring and Controlling Smoke Density

With Ionsmoke we now are able to measure the exact smoke density. Smart algorithms connect the dots over time and will adjust the smoke density accordingly to ensure a high-quality product.

Looking back on over 20 years of development our Data-Acquisition fullfills all needs for continuing food security and tracing. It includes the smoke-density colorcoded directly into the smoke-step.

EBLuft Data recording and monitoring software

EBLuft is the data acquisition and process tracking software. It monitors and records all process runs in the chamber in real time and stores the data for a later review. During the treatment of the products, the diagram with the various values is drawn on the screen in real time. This way you are prepared for all HACCP-related questions in your production facility. EBLuft data acquisition software offers the following functionalities and advantages:

- Transparency and evaluability: Select the desired controller in the EBLuft program and immediately you have all past runs at hand. If the quality of products has changed, you can track what the reason for this might be.

- Tracking of most important values: Directly on the diagrams you can show and hide the curves of important values such as times, process steps, humidity, core temperature, chamber temperature, pH values F-value, C-value, relays and more.

- Management of your programs: Access to all programs on all controllers, programs can be changed or created completely from scratch within EBLuft.

- Ionsmoke evaluation: EBLuft has an Ionsmoke algorithm which compares the current smoke density with existing curves. So you can run the same quality over the whole year and detect problems immediately.

- Error forwarding via SMS and e-mail: Get notified immediately in case of errors.

- Remote support: The installation of EBLuft software allows remote access by the EBSmoke team. This greatly simplifies program optimization and problem solving wherever your facility is located.

Even with a lot of data already recorded, the EBLuft data acquisition software still performs lightning fast. Backup copies of the databases can be played locally or on a network drive at daily intervals.

Come by our booth and let us show you EBLuft and the interaction with the controller.

Our Events

Ionsmoke Livedemo: Smoking with ionisation

Live on site we use our demonstration unit to show you how ionization works in meat smoking:

- Build of the Ionsmoke modules

- Electrostatic charging of the smoke

- Effects on meat products

- Economic factors

Ionsmoke Livedemo: Smoking with ionisation

Live on site we use our demonstration unit to show you how ionization works in meat smoking:

- Build of the Ionsmoke modules

- Electrostatic charging of the smoke

- Effects on meat products

- Economic factors

Ionsmoke Livedemo: Smoking with ionisation

Live on site we use our demonstration unit to show you how ionization works in meat smoking:

- Build of the Ionsmoke modules

- Electrostatic charging of the smoke

- Effects on meat products

- Economic factors

Ionsmoke Livedemo: Smoking with ionisation

Live on site we use our demonstration unit to show you how ionization works in meat smoking:

- Build of the Ionsmoke modules

- Electrostatic charging of the smoke

- Effects on meat products

- Economic factors