Trade fair innovationVolta SuperDrive™

The unique SuperDrive™ system is installed in thousands of industries and facilities worldwide. In fact, it is the only homogenous positive drivebelt with an installation track record of over 10 years of continuous use. SuperDrive™ is considered state of the art for hygiene, quick sanitation and savings in the cost of ownership.

Material Features

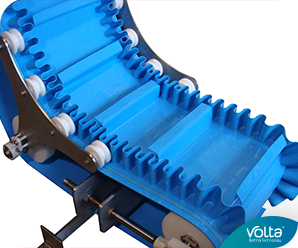

- Smooth, homogenous surface without crevices prevents bacteria and biofilm buildup

- No ply or edge fraying, compared with fabric belts; no hinges, moving parts and pins, compared with modular belts

- Simple, more hygienic conveyor construction; no heavy friction pulleys

- Reduced product waste

- Works with HACCP systems and standard hygiene/sanitation regimens (CIP)

- USDA/FDA cleared /3A Dairy/EC approved

Mechanical Benefits

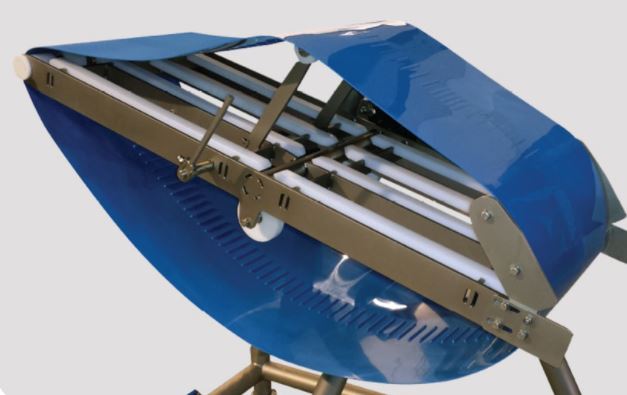

Volta Belting’s SuperDrive™ system presents a homogeneous Thermoplastic Elastomer (TPE) positive drive conveyor belt with two parallel rows of extruded teeth on the underside of the belting material. The teeth engage in a toothed drive sprocket that drives the belt with little or no pretensioning to prevent off-tracking.

- Minimal pretension reduces elongation

- Reduces noise level to a minimum

- Lightweight belting cuts back on motor and energy usage

- Easy to install

- Strong base for heat-welded fabrications

- Long operating life

SuperDrive™ conveyor belting reduces sanitation time (less changeover time between shifts and more production time), reduces maintenance, reduces water and chemical expenditures and reduces electricity consumption. It lowers bacteria counts for a cleaner, healthier product with improved product shelf life.

Available in varying belt thicknesses and hardnesses: food-grade blue and beige (Shore 55D, 53D), a Metal Detectable (MD) version (Shore 53D) and a special Low Temperature (LT) version for deep freeze applications (Shore 95A, 46D).