International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

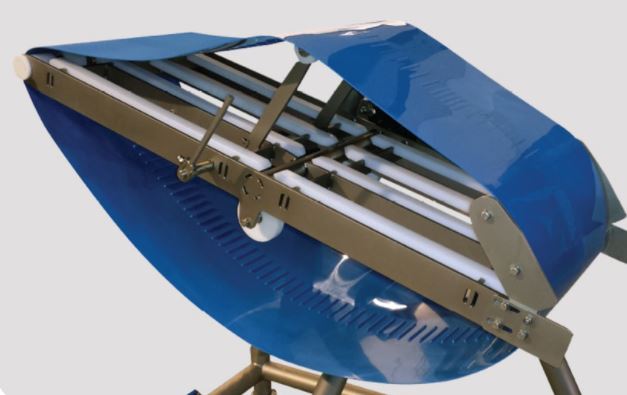

Chemical & Hydrolysis Resistant Belts

Chemical & Hydrolysis Resistant Belts

Description

Our new DR family belts have excellent hydrolysis resistant properties.

Specially recommended for applications where there are harsh cleaning and disinfecting protocols in place.

Hydrolysis resistance:

A. Increased resistance to a variety of oils, chemicals and humidity, extends belt life in many applications

B. Improved protection against sanitizing chemicals

C. Better resistance to fungal growth and less chance of pathogenic or allergenic residue

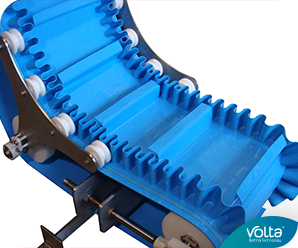

Top surface:

A. The semi-matt surface gives improved release properties

B. Scuff and scratch resistant

C. Recommended for visual applications where glare is not acceptable

Bottom surface:

A. In addition to the classic smooth bottom surface, the SuperDriveTM is also available with the new, hygienic,

fine embossed surface (coded FEDR)

B. Reduced friction which provides an increase in load capacity of 30% on steel slide beds and of 25% on UHMW wear strips

C. Less strain on the conveyor wear parts, including bearings and motors

D. Extends both belt and conveyor lifespan

E. Reduced adhesion to conveyor bed and wear strips

F. Smoother engagement with suitable stainless steel and PU molded drum motors

G. Improves performance for push applications

H. Reduces the suction effect caused by residual liquid, such as water after cleaning

I. Lowers amp draw during start up reducing strain on the belt and motor

Additional reductions in the cost of ownership.

Available with all Volta fabrications.

All our DR belts are FDA/EU approved.

Contribute to the implementation of the HACCP system.