International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

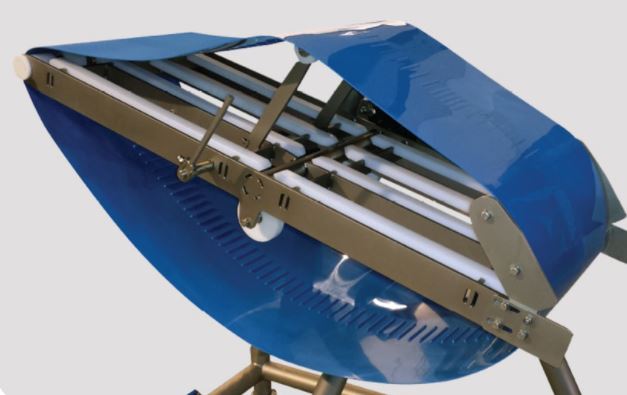

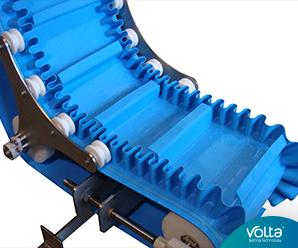

Volta Food Grade Conveyor Belts

Volta Food Grade Conveyor Belts

Description

Volta Belting’s food-grade conveyor belting is manufactured from homogeneous Thermoplastic Elastomer (TPE) to give an excellent contact surface for raw, cooked and frozen foodstuffs. Available with textured nonstick or high-grip surfaces. The belts can be installed on-site to save valuable production time and reduce contamination of the surrounding environment to a minimum.

Advantages:

- No modules, links, hinges or crevices that harbor bacteria and deposit fragments into the food

- No seams or plies that fray and delaminate; no detachment of flights and guides common plied belts

- Easily cleaned in place in very short time

- Reduced cleaning costs (labor, water, chemicals, wastewater treatment) and downtime

- Reduced loss of food

- Consistent hygiene level over time

- Lower bacteria counts, cleaner product, less investment in conforming to standards, longer product shelf life; suited to HACCP

- Easy to weld or make repairs on site

Applications in the meat industry that benefit from Volta Belting’s homogeneous materials include primary processing of meat (cutting and deboning lines, waste conveyors and offal sorting), frozen food processing, minced meat lines and small goods production.

SuperDrive™ belts are recommended for applications that involve larger lines and heavy loads, including where accumulation or side loading is employed.