International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Description

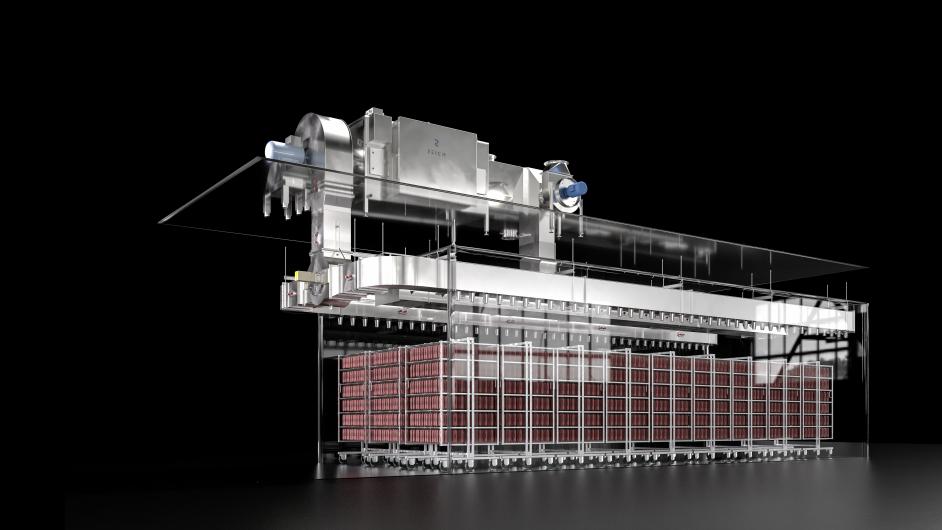

Climatic maturing units place the highest demands on the professional expertise of engineers and technologists. Manufacturing raw sausage, raw ham and other cured and air-dried products, demands exact, individual coordination of the performance parameters and geometry of the system to the requirements of the products and facilities. Precise results, intelligent and resource saving processes and optimal product handling are the main objectives.

The core of every AIRMASTER® ClimaStar maturing system is the central air handling unit. There, the air fed back from the treatment room is conditioned, meaning it is cooled, dehumidified, humidified and heated as necessary.

Fresh air is drawn in from the outside depending on the treatment process, or circulation mode is used to work regardless of the weather conditions. Systems from REICH are equipped with large air coolers for quick and efficient dehumidification.

The conditioned air is fed into the treatment room through a central fan via injection ducts. A programmable air exchange flap system ensures that the airflow can move over each row of trolleys in sequence to ensure uniform results.

The intelligent climate controls on AIRMASTER® maturing systems ensure precise, homogeneous and energy-efficient drying and maturing. The continuously adjustable air circulation system is controlled via the product’s water release, preventing formation of a dry edge on valuable goods, for instance.

In combination with the REICH ECOMIZER, a modern fresh air enthalpy system, product drying

can be optimised via the amount of suctioned fresh air. A sensor continuously measures the climatic data for the outside air and transmits this information to the controller. If the outside air conditions are appropriate, the cooling is used only to control the temperature of the circulating air and not for drying.

Because of this, the REICH ECOMIZER offers high potential energy savings. AIRMASTER® ClimaStar systems are available for any desired number of trolleys.

AIRMASTER® KKRI ClimaStar: Pre-Maturing, Drying, Cold Smoking

KKRI series climatic pre-maturing systems are designed for all pre-maturing, drying and cold smoking processes for raw sausage and raw ham, as well as semi-dry products. Other applications include air drying and cold smoking of specialised meats, such as biltong and beef jerky, as well as fish or vegetarian products. The standard range for temperature and moisture is between +16 °C to +28 °C and 65 % to 95 % relative humidity. For product groups like summer sausages and thin caliber raw sausages, higher temperature ranges up to +45 °C can also be achieved. The air flows over the products from the bottom to the top.

AIRMASTER® KRAI ClimaStar: Pre-Maturing, Drying

KRAI series climatic pre-maturing systems are designed for all maturing, drying and postmaturing processes for raw sausage and raw ham, as well as semi-dry products. Other applications include air drying of specialised meat products like biltong and beef jerky as well as fish or vegetarian products. The standard range for temperature and moisture is between +16 °C to +28 °C and 65 % to 95 % relative humidity. For product groups like thin caliber raw sausages, higher temperature ranges up to +45 °C can also be achieved. The air flows over the products from the bottom to the top.

AIRMASTER® KNRI ClimaStar: Post-Maturing, Drying, Storing

KNRI series climatic post-maturing systems are designed for the post-maturing, drying and storage of raw sausage and raw ham, as well as semi-dry products. The standard range for temperature and moisture are between +10 °C to +18 °C and 65 % to 90 % relative humidity. The air flows over the products from the top to the bottom. The combination with the opposite direction of airflow over the products in the pre-maturing system (KKRI or KRAI) creates a perfectly uniform final product. KNRI systems are configurable for trolley heights of up to 6 meters.

Advantages of the AIRMASTER® CLIMASTAR

- Exact treatment that is gentle on products thanks to precise climate control

- Energy-efficient, thanks to intelligent processes and fresh air enthalpy system REICH ECOMIZER

- Independent of weather conditions thanks to circulating air conditioning

- Uniform results thanks to programmable air exchange flap system

- Continuous speed control for fans

- High airflow for fast processes

- Complete unit and air duct system made of stainless steel 1.4301 (AISI 304)

- Fully-automated CIP cleaning

- KKRI can be combined with all REICH smoke generator systems