International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Marlen International, Inc.

Marlen DuraKut 2D Dicer with Horizontal Slicing Attachment

Explore product

Marlen Opti 100 Vacuum Stuffer

Explore product

Marlen DuraKut 2D Dicer with Horizontal Slicing Attachment

Explore product

Marlen Opti 100 Vacuum Stuffer

Explore product

Marlen DuraKut 2D Dicer with Horizontal Slicing Attachment

Explore product

Marlen Opti 100 Vacuum Stuffer

Explore productAddress

Marlen International, Inc. 4780 NW 41ST St., Ste. 100

Riverside Missouri 64150

United States

Telephone+1 913-888-3333

Fax+1 913-888-6440

Discover more from us

About us

Recognized as a global manufacturer of highly engineered food processing equipment and systems, Marlen designs and builds innovative solutions for the food processing industry.

Our premium products have long set the standard for quality and performance in vacuum stuffing and pumping, portioning, size reduction, thermal processing, and food handling.

We assure value to our customers through the highest consistency, accuracy, and product integrity. Our teams of expert engineering, design and technical personnel consult, collaborate, and partner with you to create custom solutions for your business.

Marlen has been trusted by the world’s leading food brands for over 70 years. Our world-class Solution Centers strategically located across the globe, allow processors to lean on our highly experienced food processing technologists to develop and test unique solutions for your products. Marlen is a Duravant Company and is backed by SupportPro, a complete lifecycle management program for parts and service.

It’s the Company Behind the Machine that Makes the Difference.

Marlen Overview Video

Our product groups

- Filling equipment (vacuum)

- Cutting machines / slicers for slices, cubes, strips

- Baking, roasting and frying equipment

- Continuous roasting and frying equipment

- Roasting vessels

- Ovens, baking chambers

- Cooking equipment, cooking systems (steamers)

- Other equipment for baking, roasting, frying and deep-frying

- Blast freezers

- Cooking units, cooking chambers

- Cooking units, continuous

- Hot smoking units

- Metering and portioning equipment

- Sausage filling equipment and hoppers

More about us

Special Interests

Our Brands

Afoheat

Unitherm

Carruthers

Downloads

Documents

Keywords

- Carruthers

- Afoheat

- Marlen

- Cooking, Chilling, Searing, Grilling, Kochen, Kühlen, Anbraten, Grillen

- Dicing, Shredding, Filling, Stuffing, Smoking, Würfeln, Raspeln, Füllen, Füllen, Räuchern

Our Products

Marlen DuraKut 2D Dicer with Horizontal Slicing Attachment

Just like our AdvantEdge series, our Marlen DuraKut™ series is designed and built for complete cutting versatility of fresh, vacuum-tumbled, crust-frozen, or cooked products into cubes or strips. And with the latest innovation - a shredding gang knife - there is even more versatility. Besides 2D or 3D slicing/dicing, the DuraKut can shred cooked chicken, beef or pork to give it a hand-pulled look and feel.

Equipped with VFD or servo drives, the DuraKut 2D dicer‘s powerful and precise indexing movements deliver the very best final product appearance. DuraKut’s robust durable design with tool-free disassembly, including removal of the conveyor belt and spiral knife, reduces change-over and sanitation teardown times for different cut sizes. DuraKut frames are built to the latest sanitary standards with open stainless steel channels and no tubular framing. With continuous flow processing and high throughputs, DuraKut models are controlled via a user-friendly HMI with icon-based graphics for the most intuitive interface.

- VFD-driven belts via drum motor (stainless steel motor and gear drive)

- Optional product discharge belt conveys finished product directly to dump buggy or takeaway conveyor

- Optional shredding gang knife available

- Proprietary spiral knife design reduces fines and product movement during and after slicing along with tool free removal and installation

- 12.5" (317.5 mm) wide belt features tensionless belt take-up mechanism for easy belt installation and tool-free removal

- Handles product up to 5" (127 mm) in height at any length, without the need for pre-cutting. Dice or

strip any cut size from .1181" (3 mm) up to 4" (101 mm). - Positive belt motion with center drive tensionless belt prevents belt cracking due to over-tensioning

- Continuous flow processing design allows for smooth integration into any processing line. No need for

batching. - Controlled via a user-friendly HMI with icon-based graphics for the most intuitive interface for

multilingual workforces - Open design and fewer parts reduce teardown, sanitation, and reassembly time

- Gang knife cartridge can be easily mounted and removed with tool-free disassembly

- Hinged covers and door panels with no external hinges

- EWON Wi-Fi capable (standard on servo)

- CE compliant

- Optional horizontal slicing attachment for 3D cuts

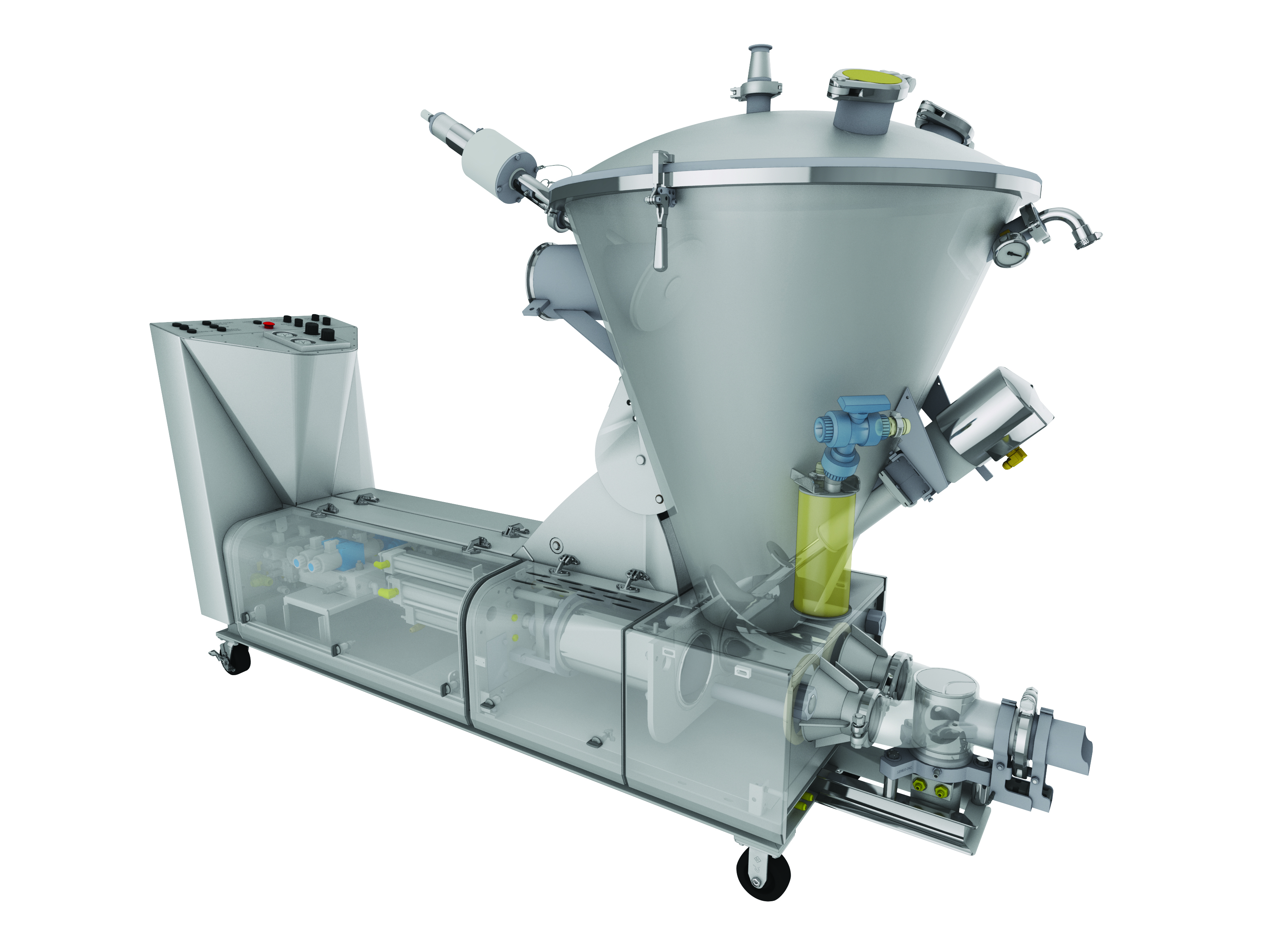

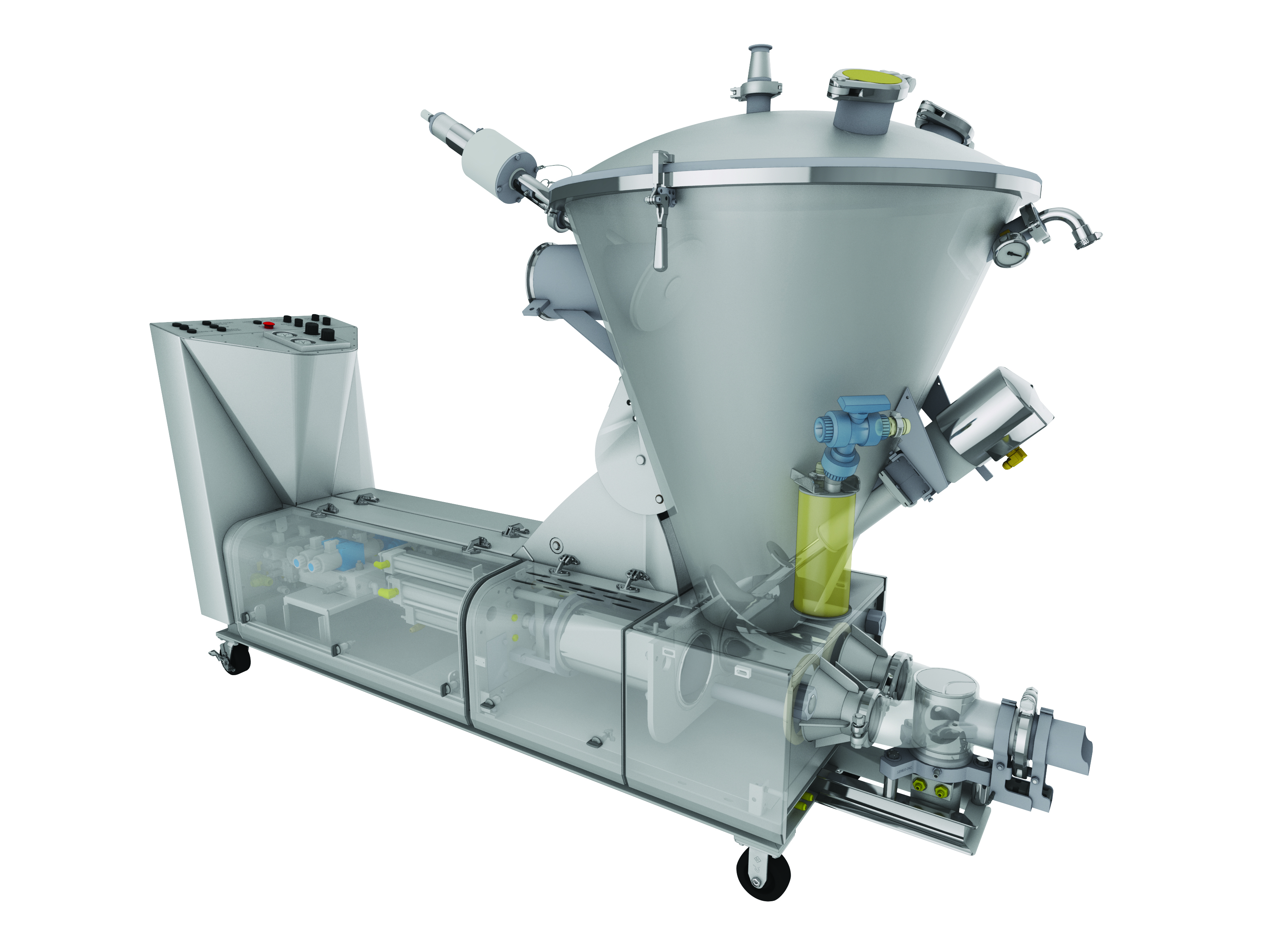

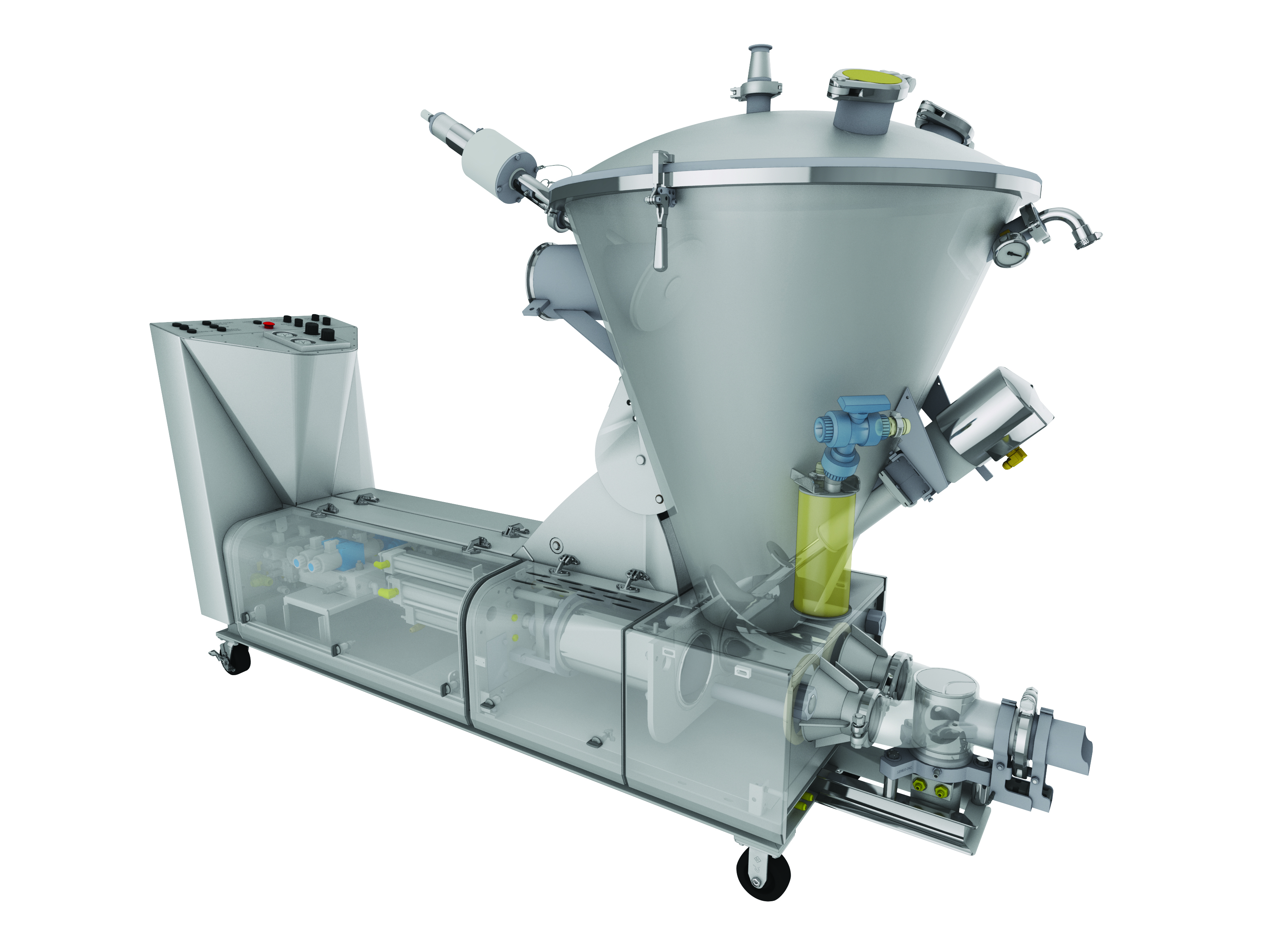

Marlen Opti 100 Vacuum Stuffer

Marlen's OPTI 100 vacuum stuffer features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements. Maximum capacity 10,000 lbs per hour, 250 psi pumping pressure. Ideal for smaller application design. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

- Simplicity; no digital controls

- All the basics of a twin piston Marlen pump at a fraction of the cost

- Small footprint and easily portable. Low profile design accommodates space constraints and heavy-duty casters provide smooth unit mobility

- 10,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- Marlen’s unique high-differential vacuum ensures maximum removal of entrapped air resulting in denser product, more accurate portion control, and longer shelf life

- Patented, hydraulically-driven front valve delivers positive shifting for continuous, even product flow, and more accurate portion weight control

- Twin-piston pumping system designed to gently deliver products to downstream processes. The zero-slip design maintains product integrity for products ranging from the highly abrasive to whole muscle. The system is gentle on your products and reduces wear on the unit, extending its life.

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- Designed for easy operation & control

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

Marlen Spiral Oven Solutions

Marlen advances Spiral Oven solutions by incorporating the latest in sanitary design, optional servo motor technology, intuitive controls with icon-based operator interfaces, and safety features. Our patented forward-reversing airflow and heating delivery methods are at the core of the oven’s design, delivering optimum product quality and consistency, while maximizing productivity per square foot. Optimal heat transfer facilitates ability to cook, dry, steam, bake, proof, equilibrate, brown, pasteurize, roast, or combination cook. Our advanced cooking systems are an innovatively compact size, minimizing energy utility requirements, and boosting overall efficiency compared to other spiral cooking systems with massive footprint and utility requirements.

The oven’s control system automatically adjusts to operator recipes with precision results on product color, texture, and moisture, so you can yield those juicy, crispy, tender, cooked-to-perfection results.

ADVANTAGES OF MARLEN SPIRAL OVENS

- Superheated vapor cooking environment creates 263 kcal/m³ more energy

- versus convection cooking, reducing cook times and improving yields.

- Integrated heat source with up to 22 air exchanges in cooking chamber per minute allows for fast startup and improved responsiveness during on-the-fly recipe changes.

- Impingement zone adjacent to heat source blows 500° F (260° C) air at speeds of up to 2,000 ft/min (610 m/min) upon product to maximize rapid color development for finishing.

- Configurable airflow components for multi-directional heating featuring Up, Down, Horizontal, and Oscillating for inside/outside belt temperature balance.

- Reduced profile internal supports and belting optimize airflow control and velocity enabling balanced air temperatures across the belt.

- Multiple probes located near the product, resulting in precise oven conditions and optimal finished product.

- Optimal heat transfer facilitates ability to cook, dry, steam, bake, proof, equilibrate, brown, pasteurize, roast, or combination cook.

- PID controlled temperature range from 203° F (95° C) to 450° F (232° C) with air temperatures as high as 500° F (260° C) in the impingement zone and up to 500° F (260° C) in the heat exchanger.

- Optional servo motors rotate at 1,000 times per second to maintain accurate, smooth belt speeds. Servos also support extreme tolerances under weights of full product loads.

- Voice of customer lead development of an intuitive icon-based touchscreen for

recipe selection, maintenance, and sanitation including multi-language options. - Ewon for remote monitoring, login for maintenance, and data logging capabilities for the ever-evolving IIoT and Industry 4.0.

- Safety design features meet CE compliance and include UL Panel Certification.

- Sanitary and compact design reduces surface area for cleaning. Large doors enable full access for inspection without any additional height needed for hood lifting.

- Optional no-leak patented sealed electrical boxes withstand 1,350 PSI direct spray to edge of silicon seal.

- Equipped with hygienic cable management system and IP69K rated stainless steel 8-port block with push lock plugs and I/O indicators for the harshest environments.

- Fully integrated CIP system uses a combination of high-volume rinse, recirculated wash, belt/brush contact, and chemical application to clean the oven. Time and temperature settings are controlled via the HMI.

- Scalable modular concept with plug-and-play utilities, and configurable belt options based on your products like number of belt tiers, usable width, and length.

- Multiple zones achieved with optional modular descending design and/or in combination with Afoheat™ Surface Treatment solutions.

- Independent inline modular spirals provide unique time and temperature flexibility.

Afoheat Searing, Roasting and Grilling Solutions

Afoheat™ burner technology is first in class for premium flame searing, infrared roasting, and custom grill marking solutions for value-added meat, poultry, and plant-based foods. Accelerate natural color and enhance flavor profile with high temperature gas infrared, flame, or authentic grill marks. Our surface treatment equipment incorporates the latest in sanitary design, adjustability, optional smart controls system with icon-based operator interfaces, and safety features. Marlen’s Afoheat burner system is at the core of the design, delivering unmatched reliability and safety, while maximizing product quality and consistency. Marlen’s expanding portfolio of surface treatment options are innovatively easy to maintain, minimize energy utility requirements, reduce fire risk, and boost overall efficiency compared to others on the market.

The burner control system automatically adjusts to operator recipes with precision results on product color, texture, and temperature, so you can precisely achieve your desired results. This all translates to reduced training time, shorter start-up and cleaning times, and increased production. Marlen key advancements contribute to a lower Total Cost of Ownership – Better Process…Better Food®.

Flame Searing

- Top and bottom of product surface receives direct flame contact

- Product appearance features artisan color; imparts “char” flavor

- Ideal for BBQ style and grilled veggies

- Burns the surface of meat and vegetables with longer dwell time

- Optimal distance to product surface 1" - 4" (25 mm - 100 mm)

Infrared Roasting

- Top of product surface receives intense radiant infrared heat

- Product appearance features uniform color; imparts “roasted” flavor

- Ideal for deli meats, sous vide, and novelty products

- Blisters the surface of meat and vegetables with longer dwell times

- Optimal distance to product surface 2" - 3" (50 mm - 75 mm)

- Adjustable product flip used for top and bottom surface treatment

Grill Marking

- Control of grill marker temperature from 392° F (200° C) to

1,292° F (700° C) - Stainless steel rings are heat resistant to 2,192° F (1,200° C), and designed for prolonged life

- Customizable branding patterns and pitches include floating rings, hash, diamond, or solid roller marks

- Optional pre-drying burners available for wet product

- Options for dual-sided grill marking

- Available as a stand-alone solution or fully integrated machine with additional burners

Marlen V750 Extruder

Marlen’s Opti-Xtrude Extruder is designed for the extrusion of viscous, shear-sensitive corn masa or potato starch. Our Opti-Xtrude model, with its zero-slip, low-shear operation is capable of extruding a variety of products with improved product appearance and a higher product quality. Our extruder creates the optimum product density with maximum oil absorption for high product quality, taste and yield. From potato rings and twists to corn chips and snacks, Marlen extruders are known as the leader for continuous pumping.

Features:

- Designed specifically for continuous extrusion of shear-sensitive materials

- Typical Applications: Corn chips, taco shells, tortilla chips, corn tortillas, masa curls, corn snacks, potato snacks and more

- Vacuum pump piston design provides even product appearance with fewer fines and spatters

- Creates the optimum product density with maximum oil absorption for higher product quality, taste and yield

- Increased capacity. Equipped with 6-in pumping cylinders and 6-in outlets connected to an 8-in outlet which allows for even product flow at a uniform rate.

- The product is subjected to very little shear which maximizes yield by minimizing waste

- Designed to be fitted with an elbow and corn chip die assembly for a consistent product appearance

- Zero-slip design and low-shear operation eliminates product degradation

- Minimizes waste. Less fines in the cooking oil decreases filtering and extends cooking oil life