International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Advanced Plate Freezing Solutions

Advanced Plate Freezing Solutions

Description

Are you looking for a smart and time-saving solution to your plate freezing needs?

Finmatec offer tailor-made plate freezing handling and automation solutions. With over 30 years of experience within the Food and Pet Food Industries in Europe, Asia and North America and with an install base of more than 50 deliveries, Finmatec have gained a strong position on the market.

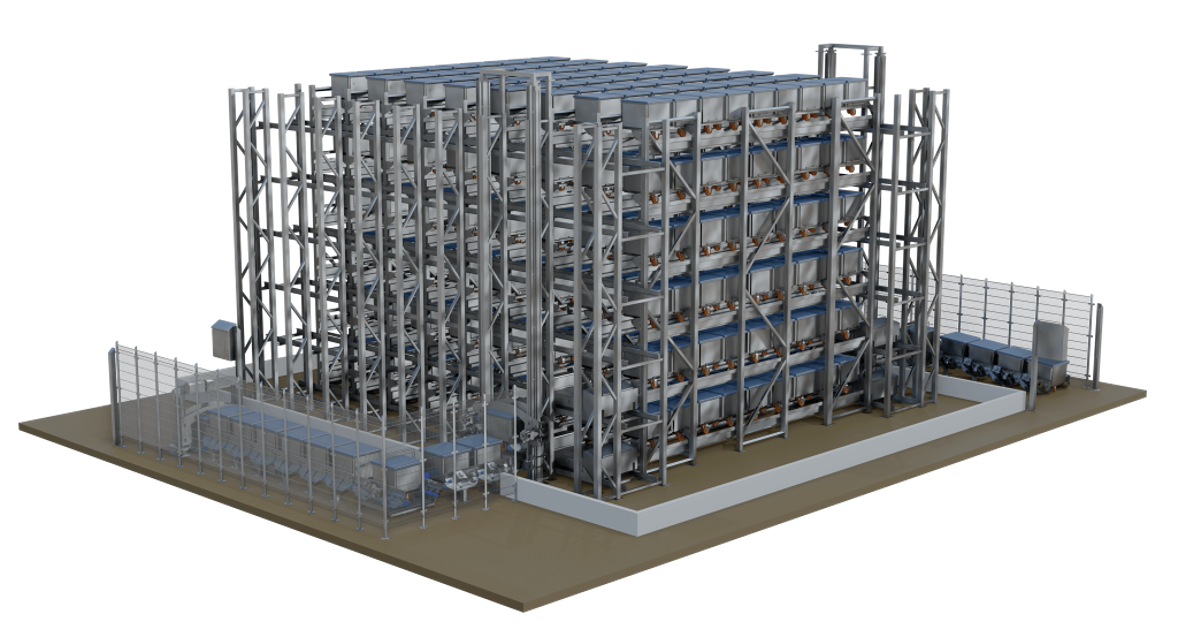

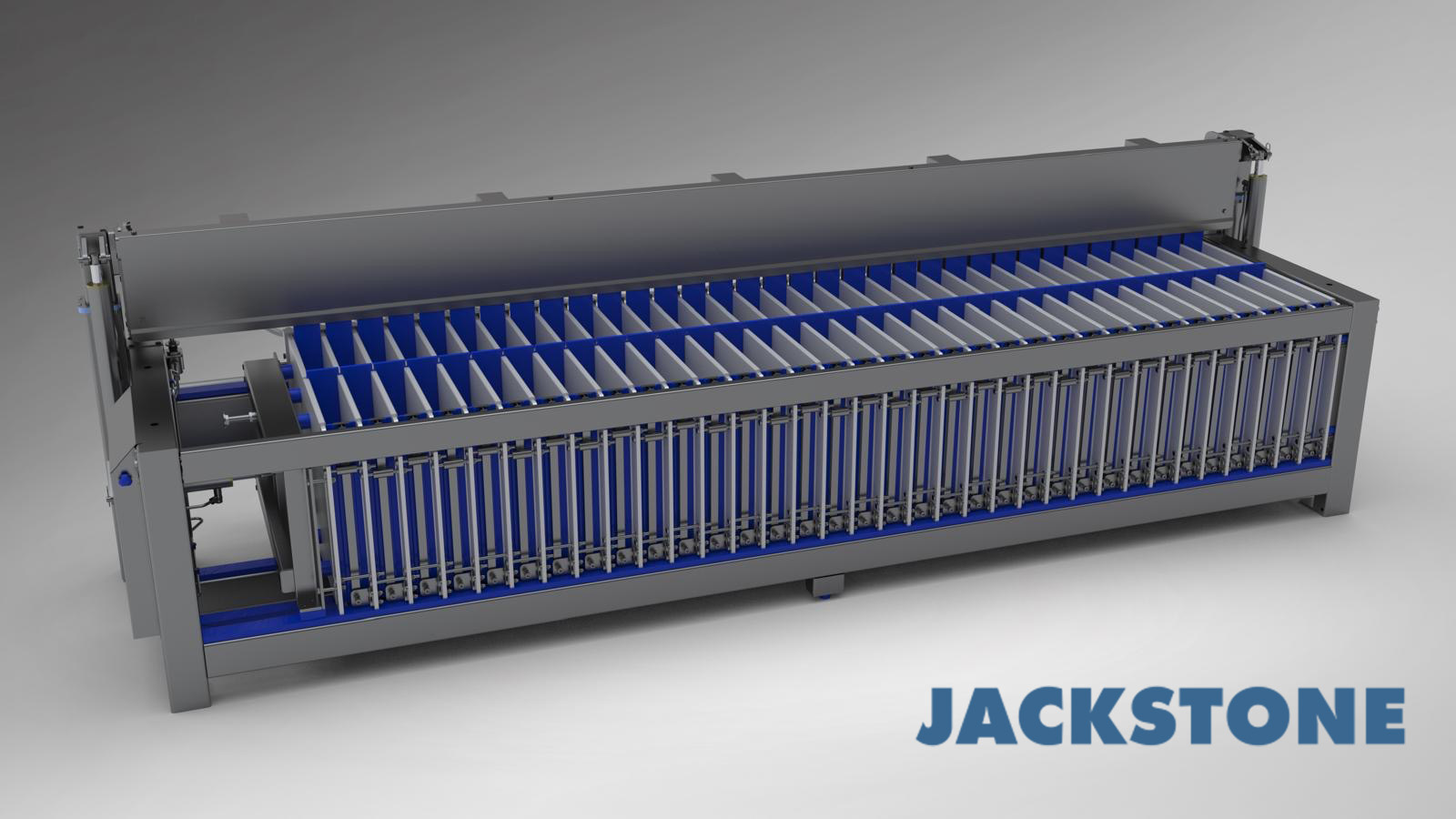

To increase productivity when block freezing raw materials like beef and pork meat, sucuk, halal meat, chicken, MDM/MSM, by-products, fish, vegetables, juice etc., the demand of reliable handling and automation solutions around vertical plate freezers is required.

Finmatec Advanced Plate Freezing Solutions offers high productivity, maximum product safety, low level of spillage, high cleanability and high ergonomy for the staff.

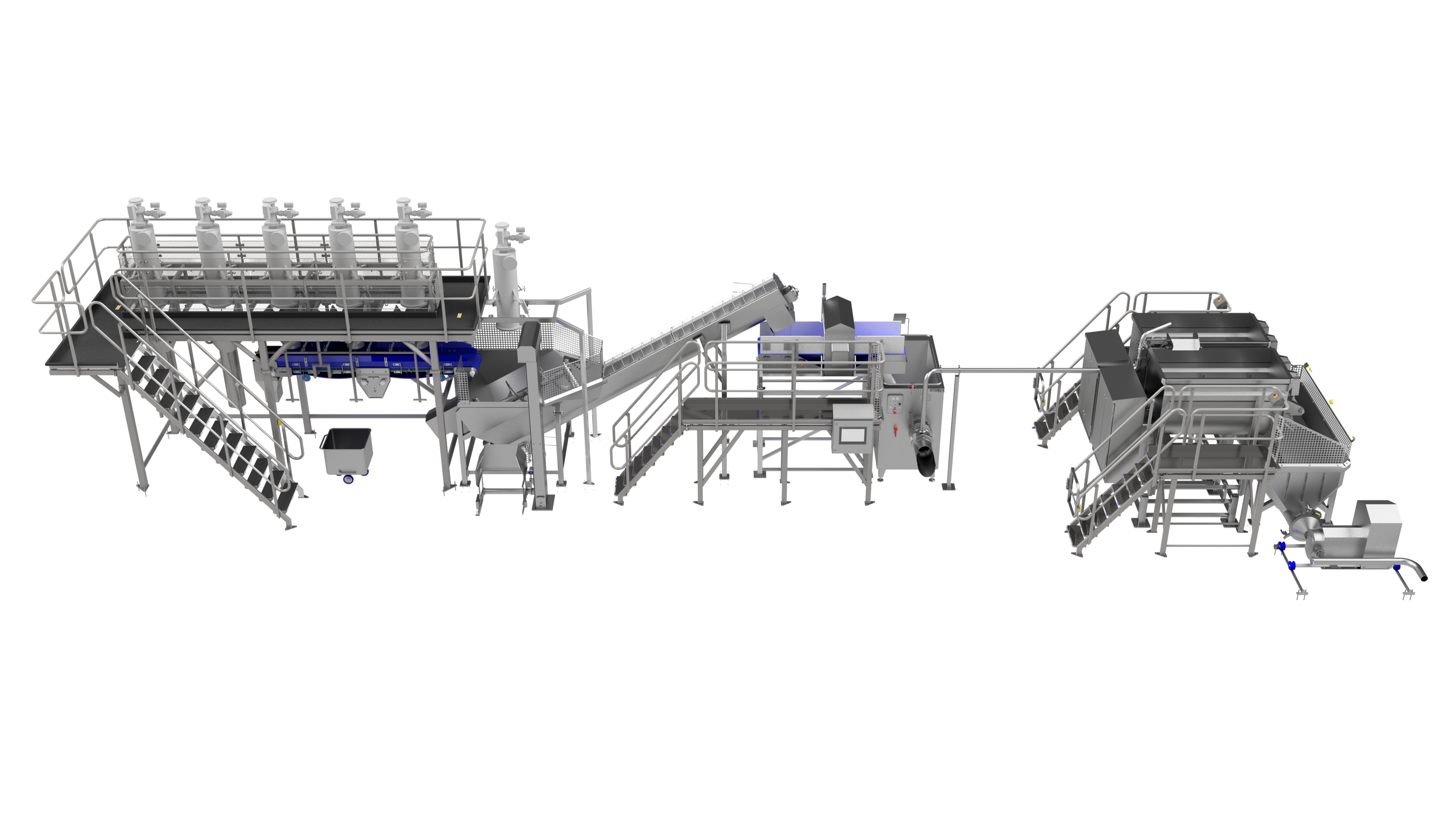

The portfolio of Finmatec Plate Freezing Solutions, ranges from basic semi-automatic handling of blocks to fully automatic palletizing systems including automatic weight registration, wrapping and conveying systems.

Additional features, such as integrated metal detection, block cutting, vacum packing, integration of PLC with customer ERP/ordering system, ensure compliance with the highest hygiene and efficiency standards. By implementing an optimized tailor-made Finmatec Plate Freezing Solution, businesses can reduce manual handling, and enhance operational flow, leading to cost savings and improved productivity.

Finmatec´s know-how and expertize to integrate - either existing or new - meat/bone separation equipment for especially mechanical deboned meat (MDM/MSM) production lines, is wellknown worldwide! We wish you warmly welcome to challenge us with your needs!

See a video here: https://www.youtube.com/watch?v=ras34Fxdnds