International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

General Planning

General Planning

Description

INTERNATIONAL GENERAL PLANNING

FALKENSTEIN is an internationally active architecture and engineering firm that has been providing general planning services for complex construction projects for over 40 years.

With over 50 employees at its locations in Aulendorf/Germany and Blumenau/Brazil, Falkenstein can look back on several hundred successfully completed projects worldwide as a high-performance general planning office.

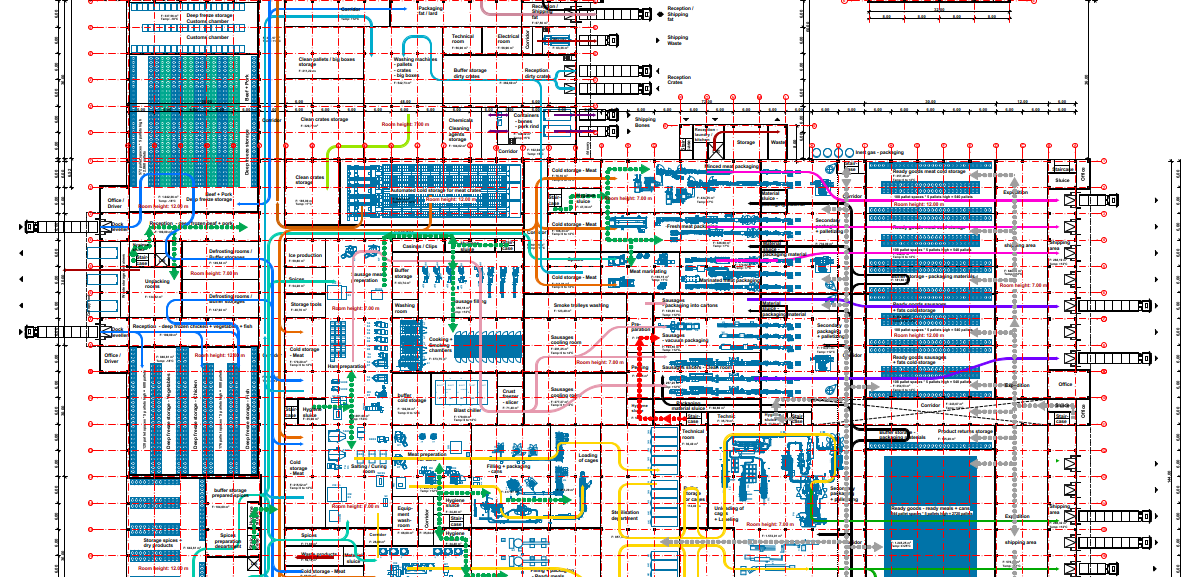

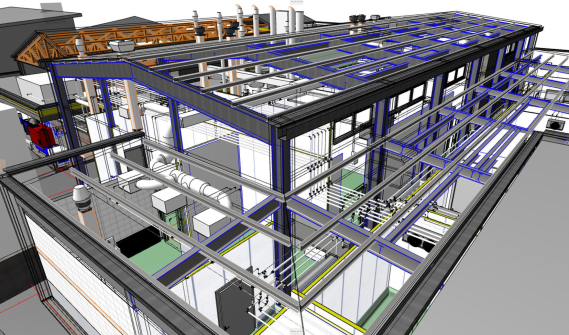

The requirements for the buildings to be constructed are demanding and, in addition to the architectural, fit-out and open space planning, also include the project planning of the technical equipment and technology. Project teams made up of architects, engineers and technologists are formed for each requirement, which develop coordinated and comprehensive planning documents under the coordination of a project manager.

A construction project is accompanied through all service phases - starting with advice on the optimal choice of site, formulation of the project objectives, planning of architecture, statics, heating, ventilation, plumbing, cooling and electrical systems, preparation of tenders, construction supervision by experienced site managers to ensure quality, right through to the turnkey handover of the project.