International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

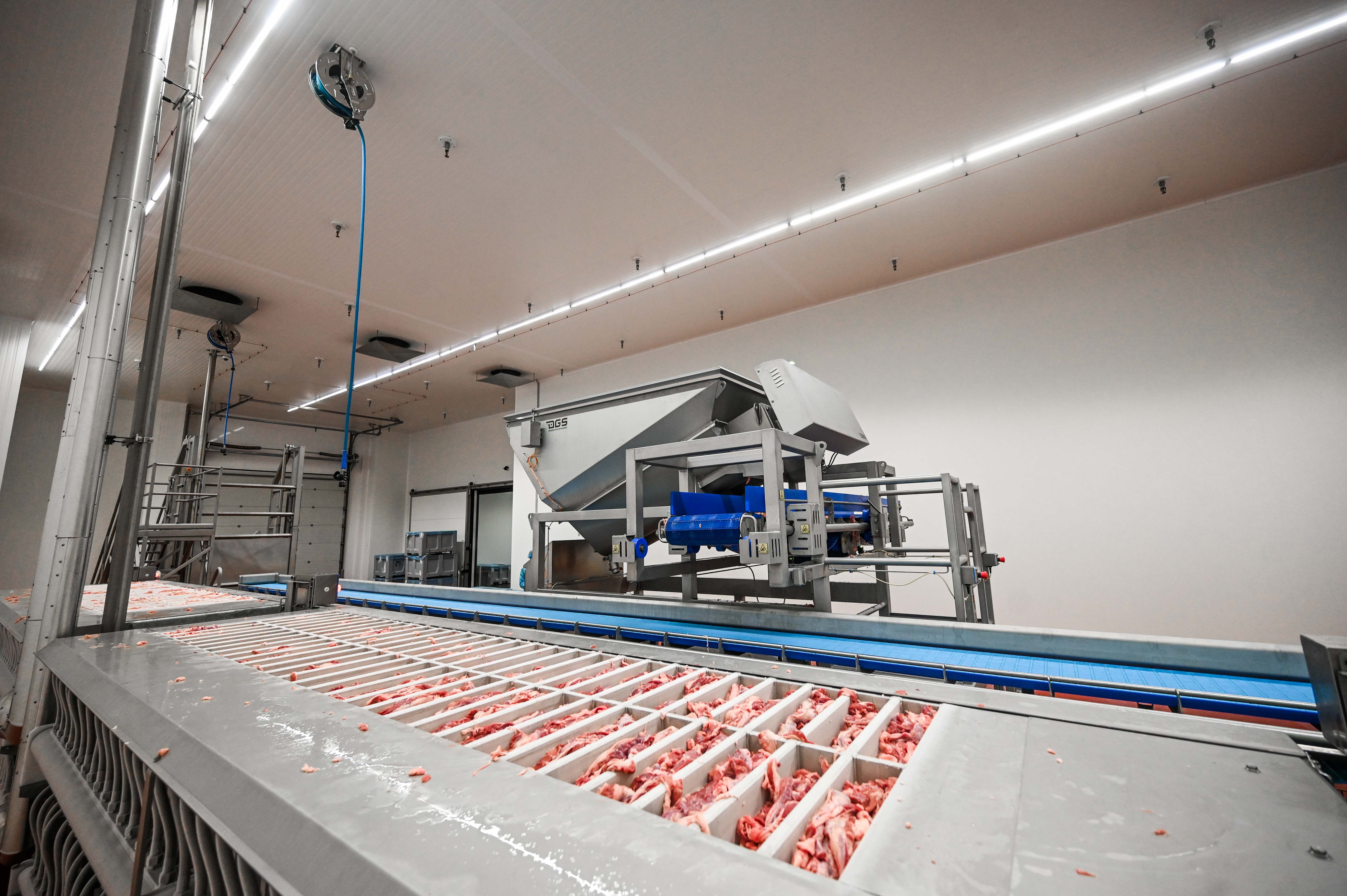

Pork Cold Rooms

Description

DGS offers efficient solutions for setting up cold rooms in pork slaughterhouses, integrating our transport systems into existing infrastructure. From manual rail systems to fully automated cold stores, we provide tailored solutions that optimize storage, cooling, and transport of carcasses, organs, and by-products, ensuring low initial contamination rates and maintaining meat quality. We also offer rapid chilling solutions to minimize dehydration losses immediately after slaughter.

Key Features:

- Minimized Contact with Carcasses: Reduces the risk of contamination by minimizing direct contact.

- Improved Ergonomics: Designed for worker comfort and safety, reducing manual labor.

- Seamless Integration: Easily integrates with other systems in the slaughterhouse for streamlined processes.

- Reduced Contamination Risk: Automated transport ensures higher hygiene levels.

- Durability & Easy Maintenance: Robust, long-lasting systems with easy cleaning and maintenance.

Solutions for Pork Cold Rooms:

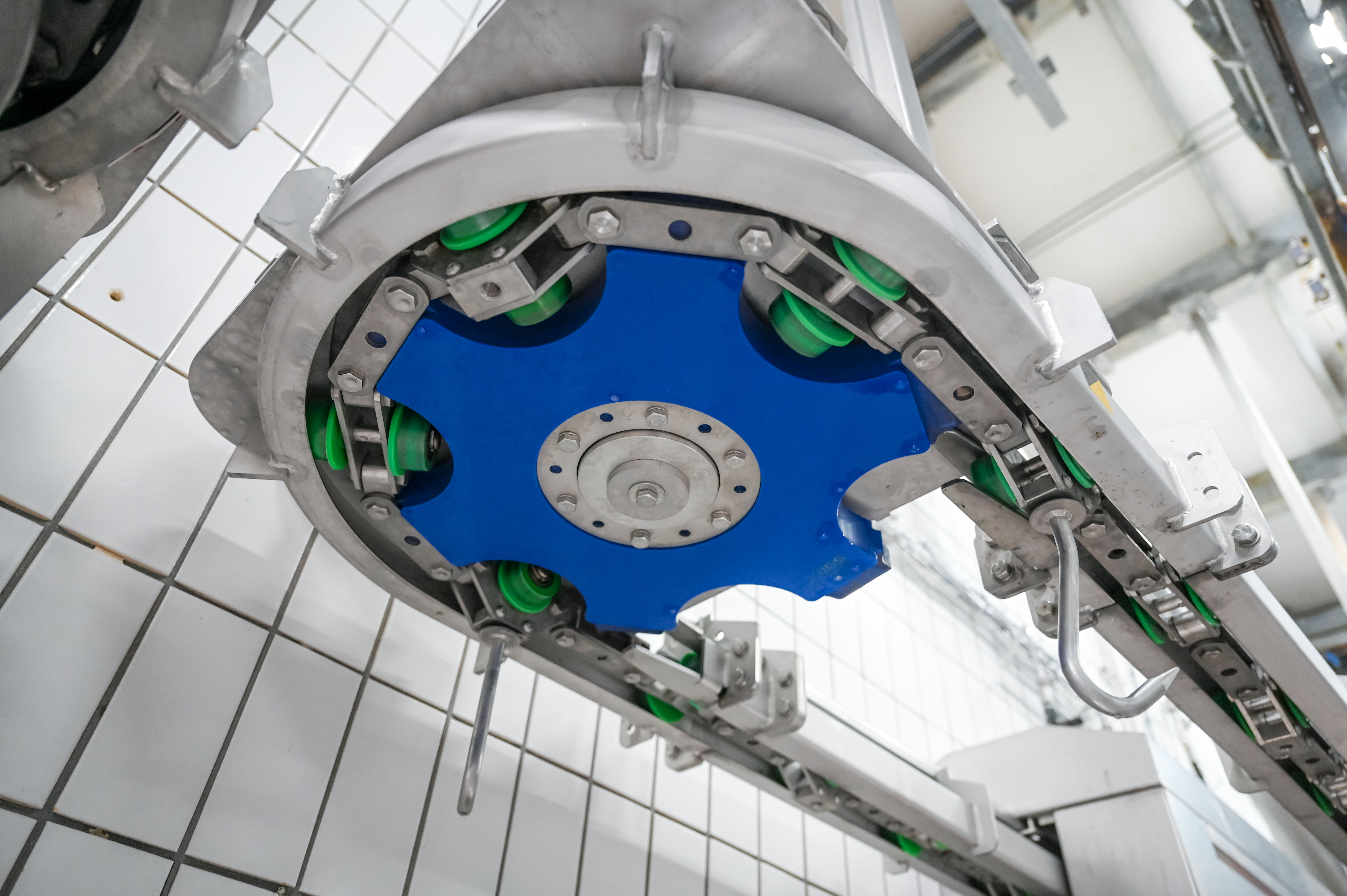

- Automated Transport Systems: We offer manual, semi-automatic, and fully automated overhead conveyor systems to transport carcasses efficiently through cooling units.

- Rapid Cooling Solutions: From spray chillers to quick chillers, we offer systems that speed up the cooling process, reducing moisture loss and improving yield.

Automation Benefits: Automating overhead conveyors reduces labor intensity, increases efficiency, and ensures consistent performance, improving overall productivity and meat quality.

DGS is dedicated to optimizing your cold storage and transport processes with innovative solutions. For more information, visit our website.