International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

ZSK Food Extruder in Hybrid Design for Production of Plant-Based Meat Alternatives

ZSK Food Extruder in Hybrid Design for Production of Plant-Based Meat Alternatives

Description

Coperion’s versatile extrusion technology allows for the production of products with meat-like structure resulting in flavor and texture profiles similar to chicken, pork, beef, and even fish. ZSK food extruders from Coperion ensure maximum throughput and best quality due to high screw speed. The closely intermeshing screws with their tight self-wiping profile eliminate stagnant zones over the whole length of the process section for an optimal mixing behavior. Moreover, the production parameters can be reliably scaled up to other machine sizes. Therefore, the results achieved on a laboratory extruder can be reliably replicated on a production scale.

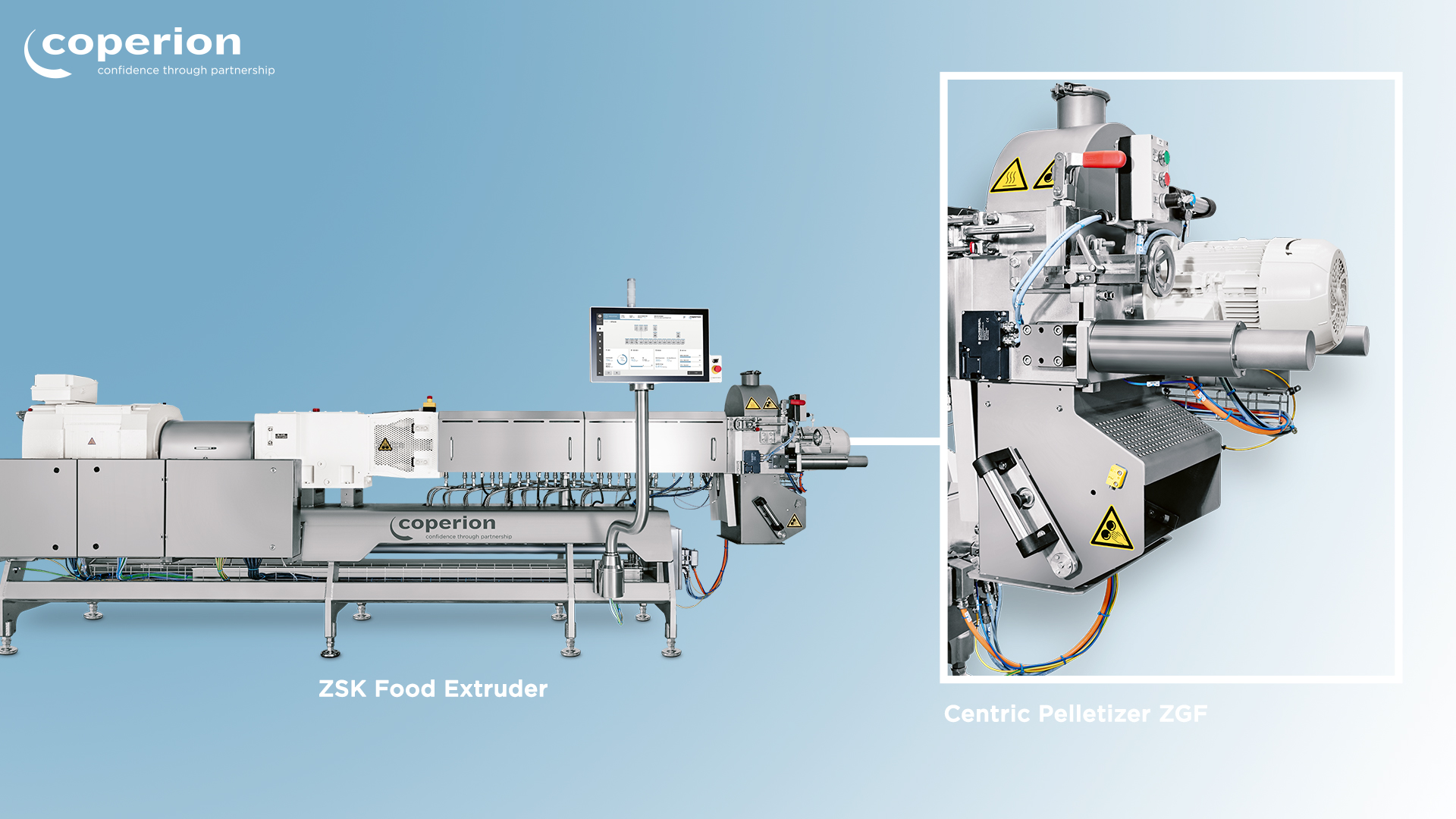

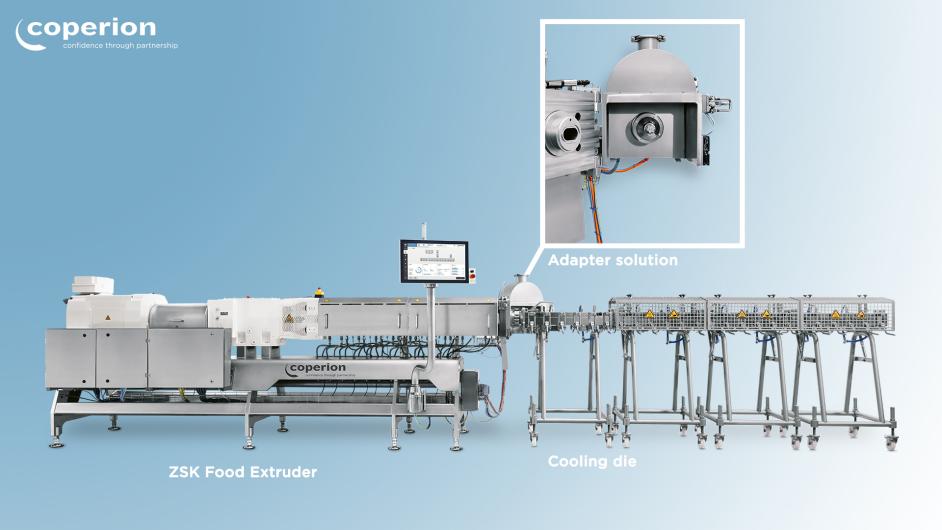

To provide manufacturers of plant-based products with maximum flexibility Coperion offers a food extruder in hybrid design which was recognized with the 3rd place at the Stuttgart Innovation Prize in 2021. This system allows for an easy switch between the production of Texturized Vegetable Proteins (TVP) and High Moisture Meat Analogues (HMMA) and vice versa. While dry textures, such as soy granules, are directly cut by a centric food pelletizer ZGF, products with a higher water content have to pass through a cooling die. There, the mass is forced into a laminar flow while cooling down which eventually creates meat-like structures. This hybrid design is optimal for companies which need to cover a broad variety of products.

Benefits at a glance:

- Maximum throughput and best quality due to high screw speed

- Optimal mixing behavior

- Closely intermeshing screws with their tight self-wiping profile eliminate stagnant zones over the whole length of the process section

- Hygienic product design: open frame, stainless steel

- High operational reliability and durability

- Suitable for the production of alternative meats, cereals, snacks, pet food and treats and more

Production Process of Meat Alternatives (HMMA & TVP)

In this video, you will get an insight into the manufacturing process of High Moisture Meat Analogues (HMMA) and direct expanded products.

HMMA: We show the extrusion of HMMA in Coperion’s test lab. Passing Coperion’s ZSK Food Extruder, HMMA is discharged using a specialized cooling die which produces a product strand exhibiting a texture closely resembling that of genuine meat.

Direct Expanded Products, such as Texturized Vegetable Proteins (TVP): Coperion's ZSK food extruder and ZGF centric pelletizer are characterized by their simple start-up process. Adjusting just a few process parameters such as water content, screw speed and temperature, can change the product properties to the desired profile. Product samples can be taken very easily directly at the ZGF pelletizer.