International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

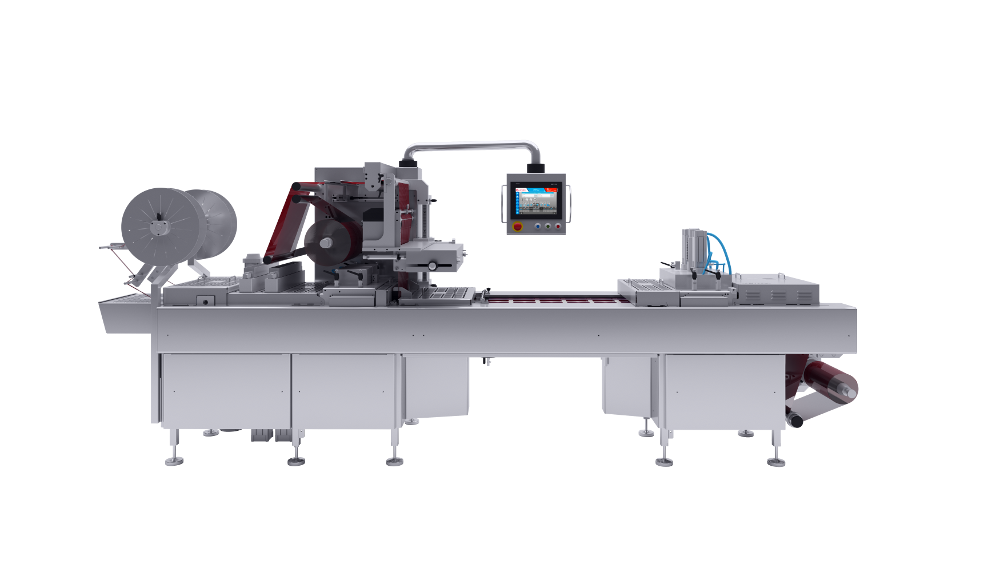

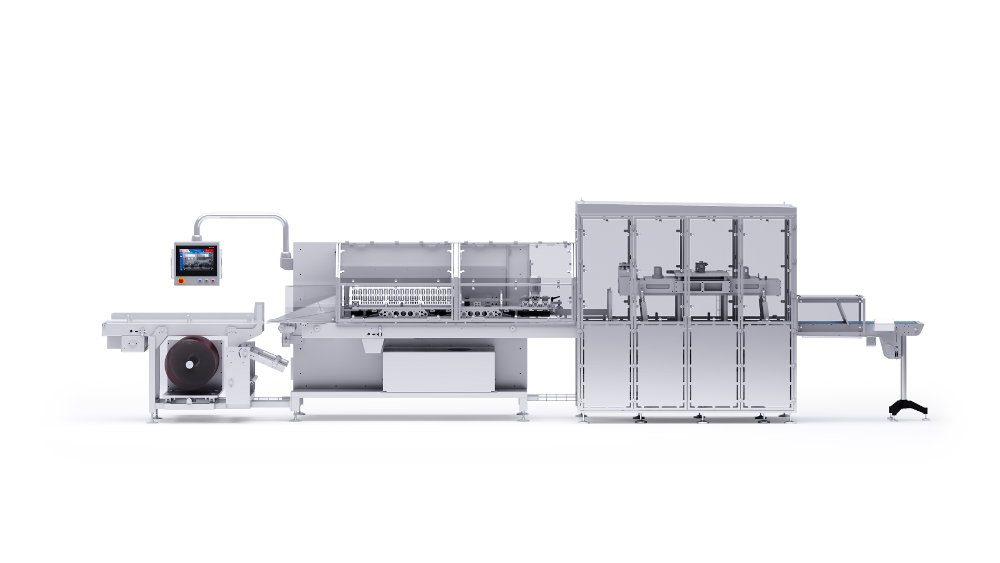

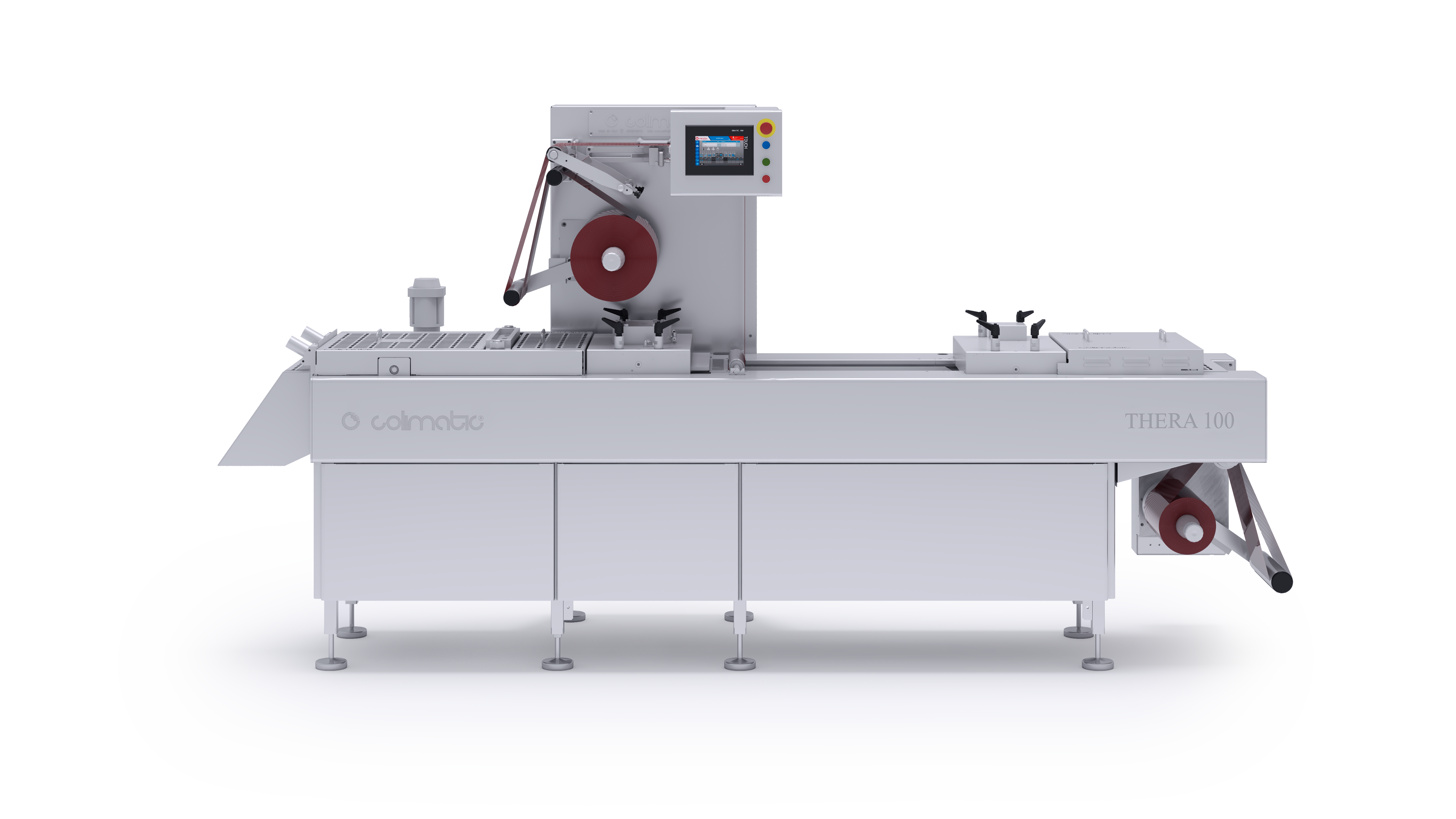

Traysealer mod. TDF1650 TDF1900

Traysealer mod. TDF1650 TDF1900

Description

This brand new and revolutionary series has machine frame completely realized in stainless steel with meatl sheets obtained by laser cutting and electrically welded holding components. The high packaging flexibiliy is guaranteed by the Brushless servomotor management which optimize the functioning cycle according to the product exigences.

Frame made entirely of stainless steel AISI 304L with parts realised from laser cut and welded carriers.

Machine movements management through Brushless servomotors in order to allow an interconnection between the various elements in motion by means of electronic cam.

Independent regulation and interconnection of the various machine components via cams.

Energy recovery system generated by the machine motor during braking to drive other motors installed in the system (KERS - Kinetic Energy Recovery System)

Possibility of use plastic, aluminum, cardboard polythene, plastic film cover, aluminum or PE-coated cardboard precut trays.

New graphical interface for management and control of all components of the system

Inlet conveyors driven by servo motor, for positioning and spacing of the trays according to the scheme of pushers.

Pushers driven by servomotors for the grip of the trays and their positioning in the sealing mold

Towing rollers films with the servo motor, for adjusting the performance according to the type and thickness of the material.

Quick format change, thanks to the ease of disassembly pushers and dies, and the use of trolleys bolster heated.

High level of hygiene, with realization of inclined planes and dismantling system of the tapes.

Ability to integrate with automatic loading systems product devices in end of line (labeling machines, checkweighers, boxing, aligners), systems for automatic printing of variable data

Easy management of packaging line via touch-screen and dedicated program for monitoring and parameter variation machine.

Possibility of MAP packaging and Skin.