International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

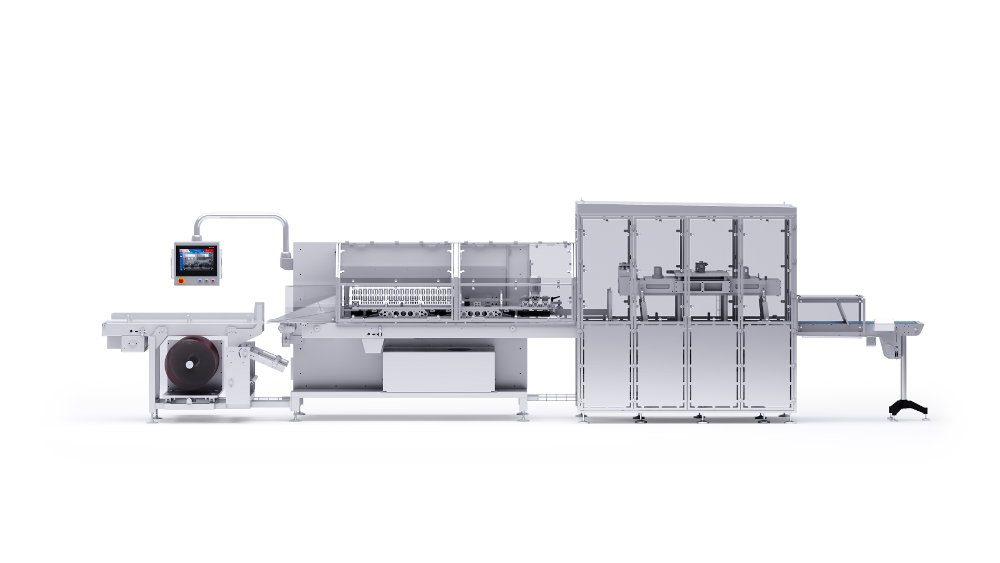

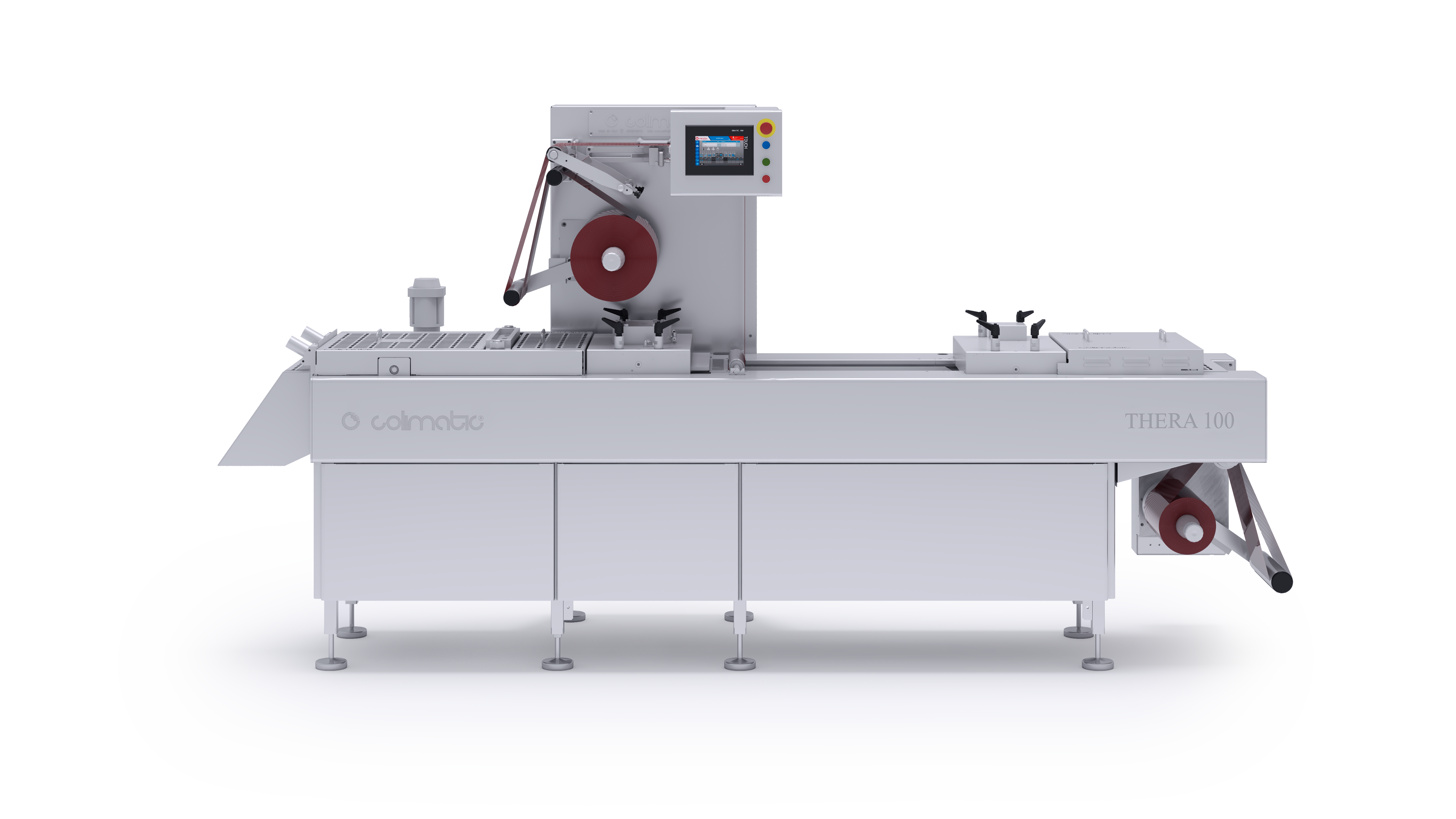

Thermoforming line FFS THERA650

Thermoforming line FFS THERA650

Description

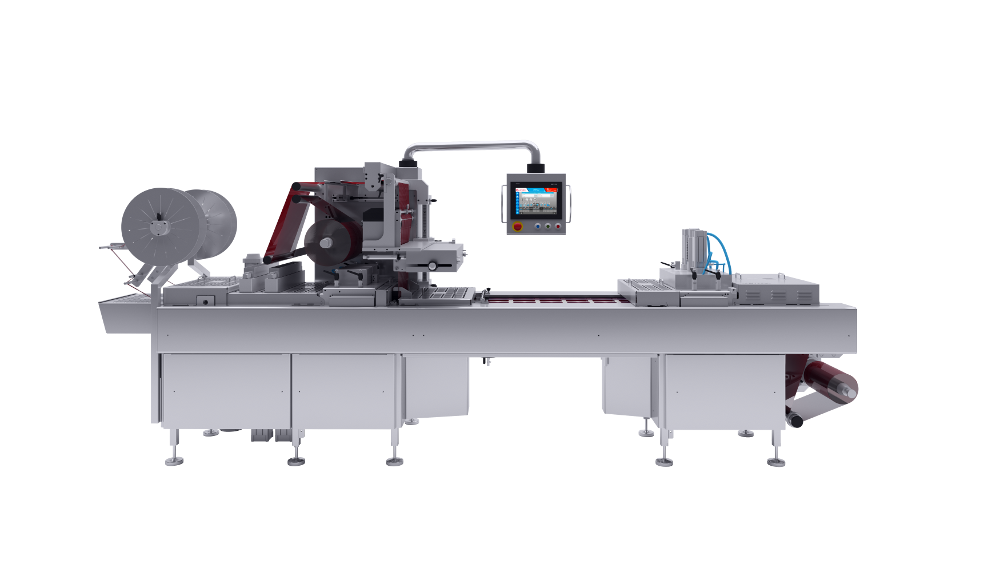

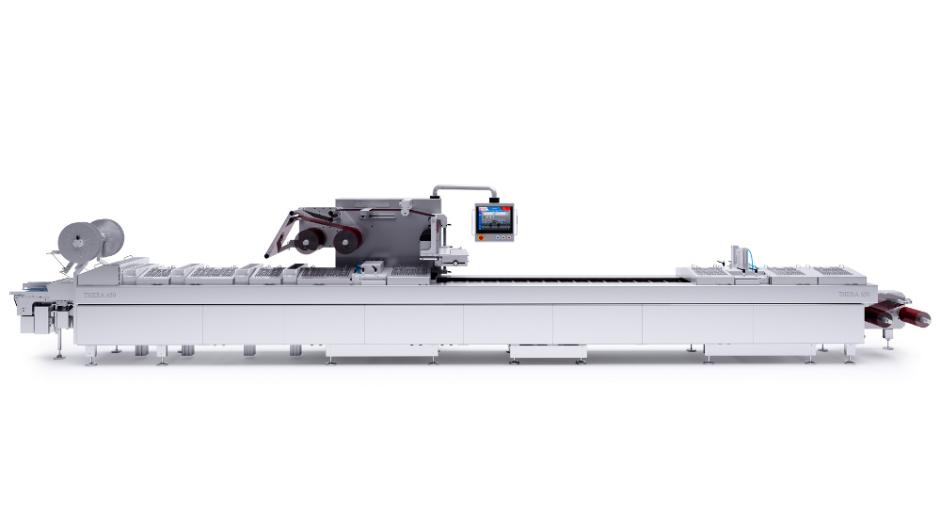

The distinctive trait of our THERA 650, is its modular frame. This makes it suitable to any kind of production need, die configuration and speeds: making this machine also a versatile option.

Our THERA 650 is equipped with the best Colimatic technology: thanks to its high outputs, it is the perfect solution for high productions and big-sized products.

HYGIENE Sloped surfaces for complete washdown and frame in stainless steel AISI 304 suitable for use in the Clean room or in corrosive environments

BUILT TO LAST Durability, integrity and consistent performance

EASY access for maintenance and service

TOP PERFORMANCE The highest packaging output level, for this machinery range

TAILOR-MADE : No limits to customization with modular frame adaptable according to production requirements

COMPATIBILITY & synchronizations with a wide variety of devices & accessories

USER FRIENDLY with latest next-generation HMI & intuitive options

COST SAVINGS up to 30% on waste from packaging materials

SOLID Stainless steel frame & components

Standard components (FESTO, BUSCH, SIEMENS) for better management of the spare parts

QUICK die configuration change, thanks to the hinged opening chamber for easy access to the molds

MULTIPLE INDEXEX ability, through facilitated system for the replacement of the chambers or with high technology Double Index patented function (Variable Format), with installement of two chambers.

SKIN & SHRINK technology available

INDUSTRY 4.0 Through LISA® (a patented software for the integrated management of production in the "Industry 4.0" environment) Colimatic can intervene remotely to minimize unexpected machine downtime. This is enabled through real-time control of spare parts, management of maintenance and continuous monitoring of the machines vital parts. Integration to the customers IT system for work orders acquisition and processing all the data and specifications that contribute to the quality of the final product. Thanks to the LISA® software package all process data can be stored and made available. The retrievable data includes information relating to performance (OEE) but also all the process parameters linked to the production batch for total traceability of the packs produced. Customer Care guarantees the fulfillment of any request for spare parts within 24 hours.