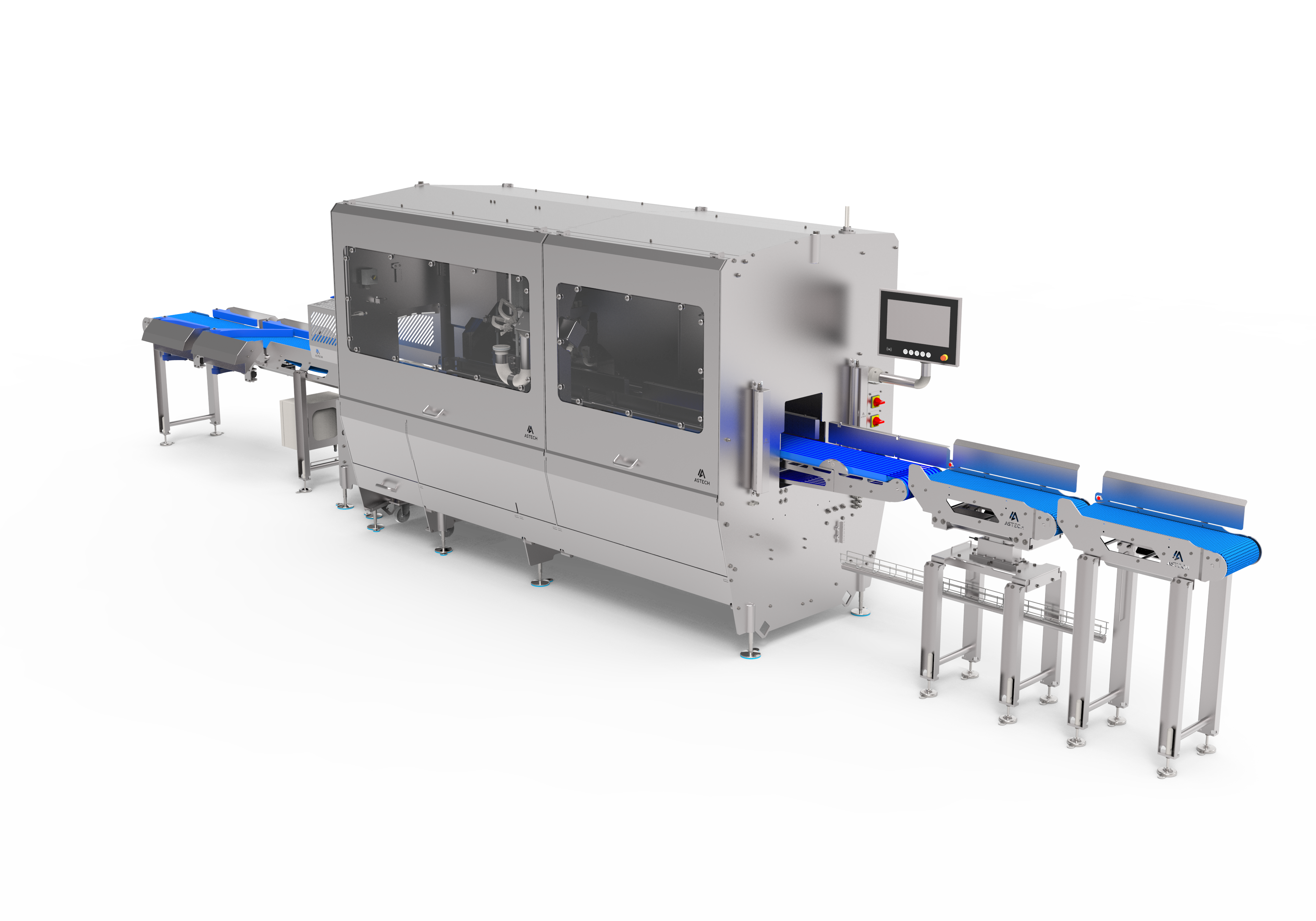

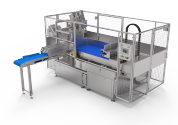

Astech has designed an automatic band saw for cutting both fresh and frozen bone-in or boneless product. It offers a high production rate, precision in the thickness of the cut, and the highest safety level during its use.

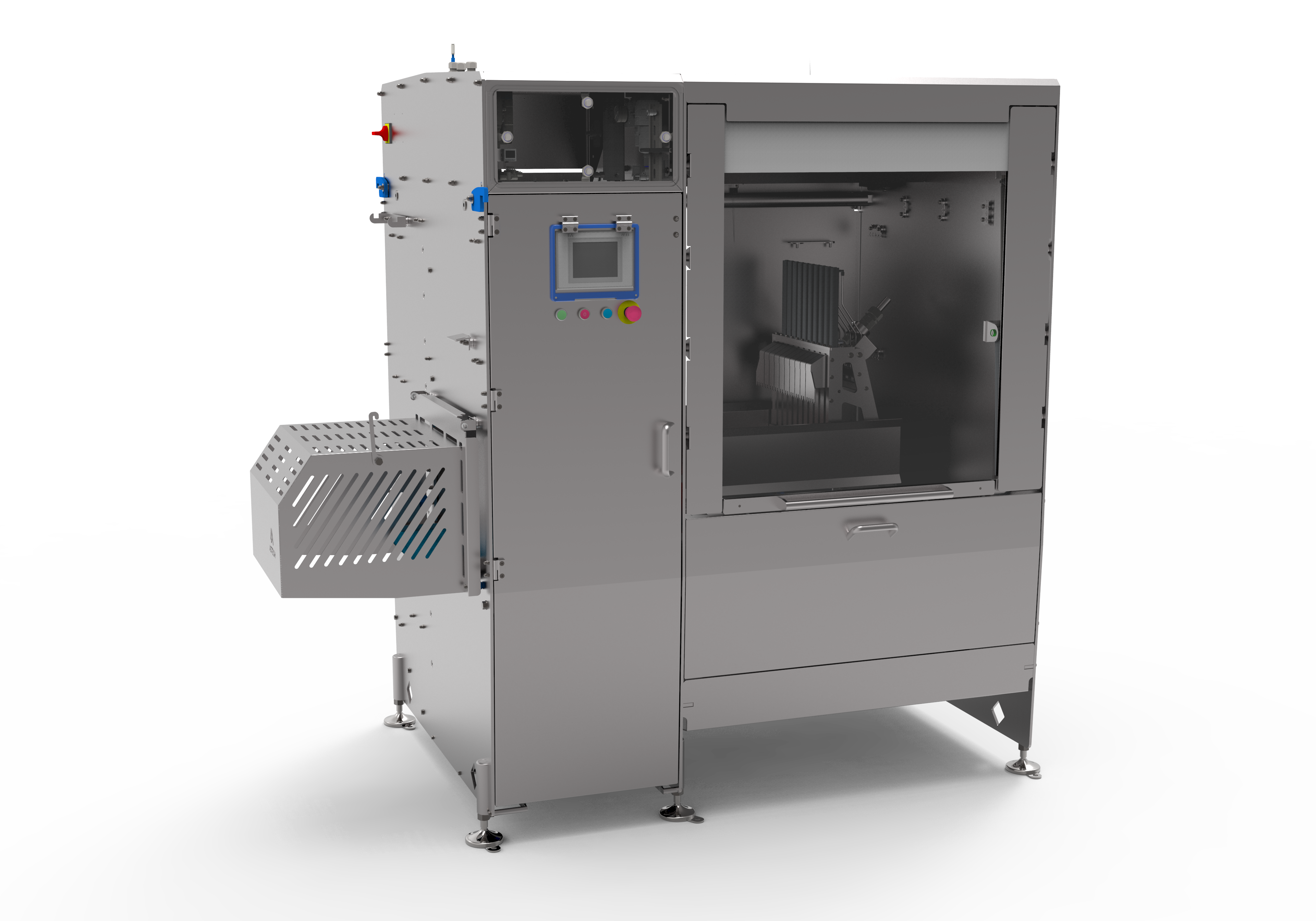

THe model 3.0 brings a complete closed and hygienic design that ensures your operator's safety.

FRESH BONE-IN PRODUCT CUTTING

Now, the SRA cuts fresh bone-in product (not frozen) bone or with fishbone. The limitation of the temperature of the product to be cut is reduced, so the range of the product to be processed increases

THE MACHINE IS MAINLY USED FOR, BUT NOT EXCLUDED TO

POULTRY (turkey, chicken)BEEF (loin, cutlets, ribs,…) LAMB (leg, rack, skirt, shank,…) FISH (tuna, blue shark, hake, salmon,…) PORK (knuckle, ham, loin, ribs, CHOPS…)

SRA ADVANTAGES

QUALITY OF THE CUT. Constant cutting speed ensuring high quality cuts.

HIGH PRODUCTION. A single operator can operate 2 machines simultaneously.

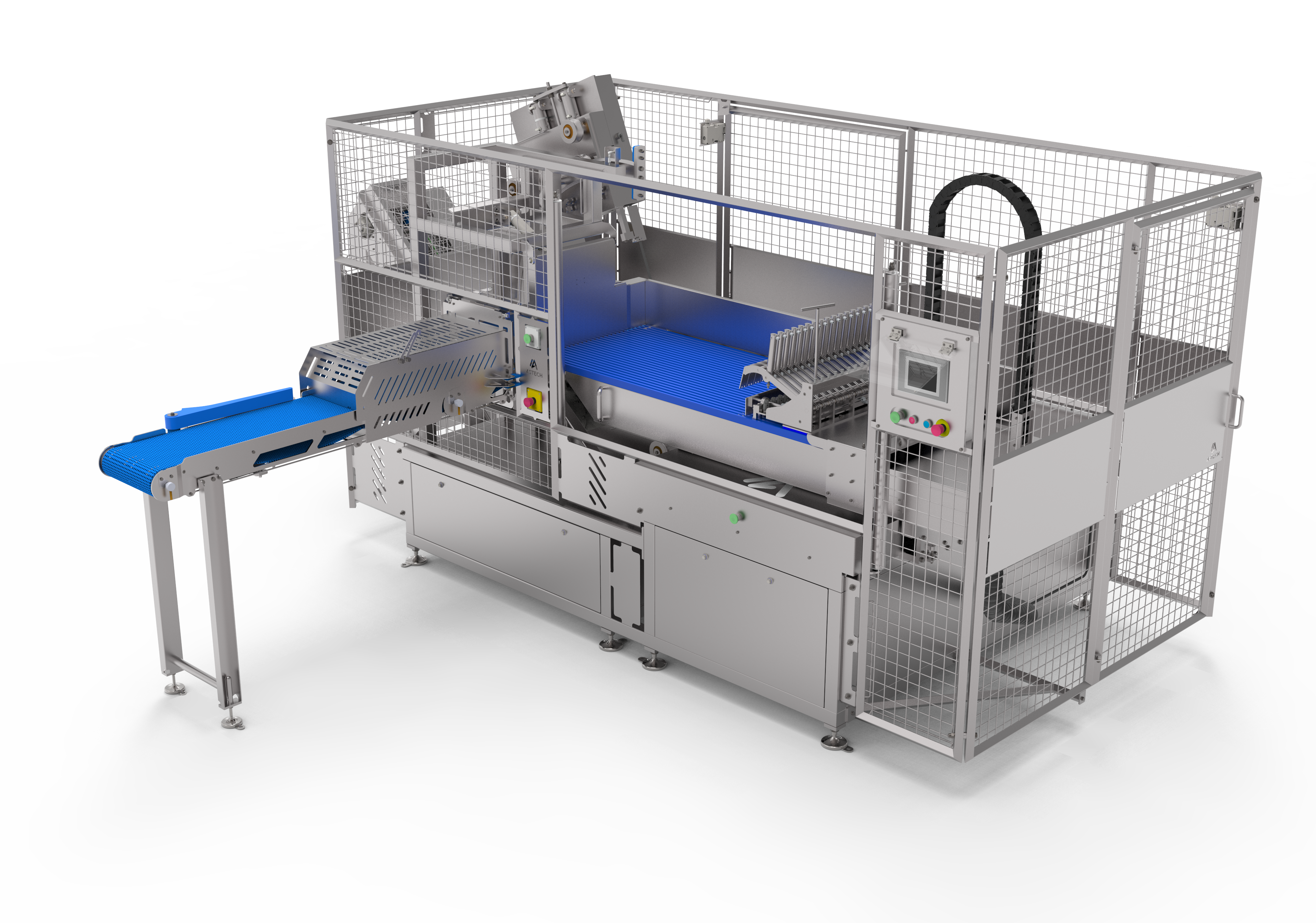

OPERATIONAL VERSATILITY. The integrated programme offers a wide range of options for cutting configurations. Furthermore, by changing the grippers, different products can be cut.

SAFETY. The whole machine is surrounded by a fence to prevent access to the interior, leaving free the loading area protected by a safety light curtain that stops the cycle whenever it is broken.

HYGIENE. The entire machine, its mounting hardware and the safety fence are made from stainless steel and plastics that are suitable for use in the food industry.

ROBUSTNESS. The machine’s chassis is made from high-thickness tubes and sheets, welded together and then machined as a whole for exact adjustment and precise movements.

PRECISION. All of the cutting movements are performed by servomotors, and all of the calculations are made by computer.