International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

Accuratech ApS

Discover more from us

About us

Join the journey

At Accuratech, we have been specializing in the digitalization of the food and manufacturing industries since 2004. We develop software solutions aimed at enhancing our clients’ bottom lines and serve as a skilled partner in their pursuit of digital and efficient production. Our focus is on creating value, and through our robust strategic partnership with Scanvaegt Systems, we offer both standalone software solutions and comprehensive solutions to the food and manufacturing industries.

We deliver software solutions of the highest quality

ScanPlant NG is our proprietary MES system, comprising various dedicated standard packages tailored individually to your production needs. This ensures you receive a completely customized solution that supports your unique needs and seamlessly integrates with other existing systems and routines.Our solution ranks among the market’s most integrable systems, accommodating both third-party systems and the digitalization processes that future-proof your business.We provide a unique support setup offering 24/7 support, 365 days a year. This ensures maximum uptime for our clients and secures a stable and efficient production.

Solid and Well-Consolidated Group

Accuratech is part of the solid and well-consolidated Scanvaegt Group. We operate in Denmark and on international markets, with notable references in the food and manufacturing industries. Our ambition is to enhance our clients’ competitiveness through innovative and value-creating collaborations.

Our Values

Accuratech is driven by strong values including Partnership, Passion, Responsibility, and Value Creation. We are committed to delivering the best solutions to our clients. Our employees’ extensive process knowledge and expertise afford us a unique understanding of our clients’ needs. Through robust partnerships, we develop, maintain, and future-proof ScanPlant NG, ensuring it delivers unique value now and in the future. We provide comprehensive and effective solutions to the food and manufacturing industries, ensuring our clients are always ahead.

- Partnership. At Accuratech, partnerships and building relationships are integral to our DNA. We understand the challenges our customers and partners face, take ownership, and are committed to fully achieving our clients’ goals. Together, we consistently strive to go the extra mile for our partners and customers.

- Responsibility. At Accuratech, we do not take responsibility lightly. Good conduct, integrity, and social responsibility are expected of all our employees. We trust our partners, customers, and each other, and we are accountable for our solutions.

- Passion. At Accuratech, passion is something we all share. We are focused on solutions and are constantly motivated to find the best outcomes for our customers and partners. We achieve this by owning our projects and showing a deep interest in acquiring new knowledge

- Value-Creating. At Accuratech, our goal is to create value. Everything we do is aimed at adding value for our customers, partners, employees, and the company itself. This involves being cost-aware and prioritizing knowledge sharing across various fields. By ensuring this, we are always prepared, thereby continuously creating value.

Social Responsibility

At Accuratech, we are convinced that everyone has a responsibility to make decisions that promote societal well-being and positive development. We have always prioritized the social aspect by providing financial support to several charitable organizations and actively employing young people with special needs, contributing to their personal and professional development. As a company, we value diversity and inclusion, actively striving to recognize and accommodate each other’s unique needs and differences.

Our product groups

Keywords

- Manufacturing Execution Systems

- Traceability

- Warehouse Management

- Performance Monitoring

- Quality Control & Management

Our Products

Performance Monitoring

For modern food producers, having direct and up-to-date access to key performance indicators (KPIs) such as yield, throughput, downtime, quality, and efficiency is crucial. Presenting this data through visual dashboards or information screens offers a significant advantage. That’s why we’ve designed every ScanPlant NG workstation and production area to collect data for visualization, reporting, and analysis. This functionality spans across different production areas, providing critical insights into factory performance. These dashboards, developed in collaboration with our customers, offer vital insights into factory performance and can be displayed on large screens in production areas, production terminals, or directly on management’s personal mobile devices. This flexibility ensures that everyone—from the shop floor to management—has immediate access to the data needed to optimize operations and drive continuous improvement.

KEY BENEFITS

- Real-Time Production Insights: Access real-time data on production performance.

- Customizable KPIs: Tailor key performance indicators to meet specific business needs.

- Multi-Device Accessibility: View dashboards on large screens, terminals, or mobile devices.

- Enhanced Decision-Making: Improve decision-making with instant data access.

- Supports Continuous Improvement: Drive operational efficiency and ongoing improvements.

KEY FUNCTIONALITY

- Real-Time KPI Tracking: Monitor key performance indicators across production processes in real-time.

- Custom Dashboard Design: Collaboratively design dashboards tailored to your needs.

- Multi-Device Availability: Access dashboards on large screens, terminals, and mobile devices.

- Instant Performance Alerts: Receive immediate alerts and notifications on performance.

- Comprehensive Data Integration: Integrate data from various production systems for complete insights.

With ScanPlant NG dashboards, you can empower your team with real-time insights and data-driven decision-making, enhancing operational efficiency and supporting continuous improvement across your production processes.

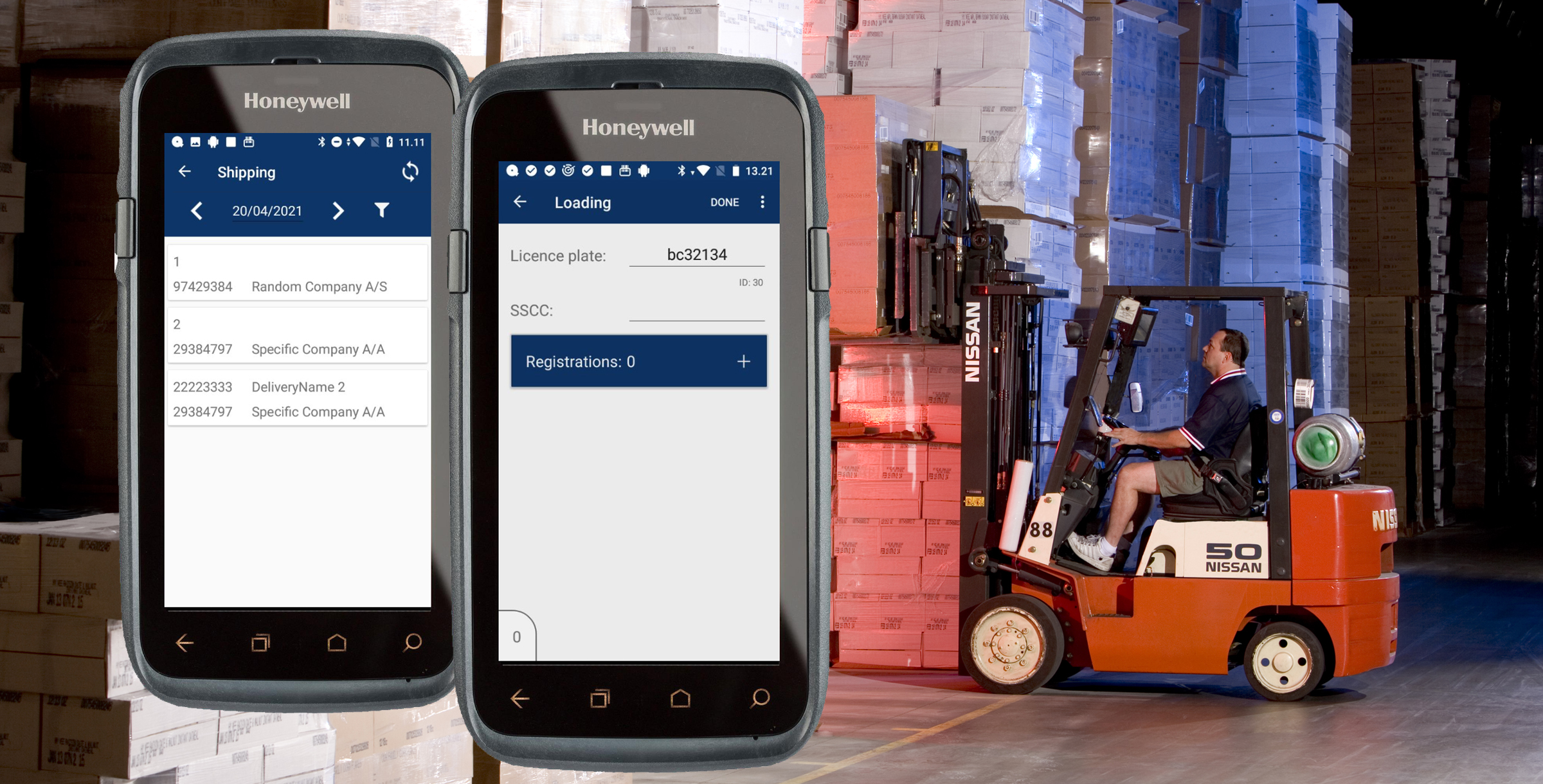

Outbound Logistics

In the food industry, the order picking and shipping process is one of the most critical stages, acting as the final step before products reach supermarkets and consumers. Delivering the right product, in the right quantity, and on time is essential in today’s competitive business environment. The ScanPlant NG Mobility Module supports order management, inventory control, movement tracking, palletizing, order picking, and shipping processes. This module comes with pre-configured solutions that reflect best practices, offering high configurability and flexibility to meet your specific needs.

KEY BENEFITS

- Assign Packages and Pallets: Efficiently allocate packages and pallets to orders and shipments.

- Real-Time Order Visibility: Access order, order line, and shipment details instantly.

- Streamline Shipments: Create and manage shipments with ease.

- Enhanced Palletizing Control: Improve accuracy in the palletizing process by monitoring product and order details.

- Accurate Billing Data: Increase the validity of billing data with no redundancies.

KEY FEATURES – PALLETIZING

- Automatic Palletizing: Automatically palletize based on weight or quantity per order, inventory, or packing line. As boxes are created via a scale, grading system, or other methods, they are automatically assigned to a pallet.

- Manual Palletizing: Conduct manual palletizing using handheld scanners to scan each box label on the pallet, facilitating either inventory management or order picking.

- Comprehensive Pallet Labels: Generate pallet labels with general pallet information and detailed item data as pallets are completed, orders are fulfilled, or pallets are manually closed.

- Customizable Labels: Labels can include customer or warehouse information, such as storage locations.

- Real-Time Floor Management: Manage operations in real-time using handheld devices or wall-mounted industrial terminals.

KEY FEATURES – SHIPPING

Shipping involves assigning units to customer orders and deliveries before the physical shipment occurs. Products or orders can be tracked to trucks or containers, ensuring traceability to cover the whole back-end logistics process.

- Transport Information: Access detailed transport data, including truck or container specifics.

- Shipping Documents: Generate and manage essential shipping documentation.

- Real-Time Shipping Management: Oversee shipping operations in real-time with handheld devices or wall-mounted industrial terminals.

- Multi-Order Shipments: Handle shipments that include multiple orders efficiently

By integrating the ScanPlant NG Mobility Module into your operations, you can enhance the efficiency, accuracy, and traceability of your order picking and shipping processes, ensuring customer satisfaction and operational excellence.

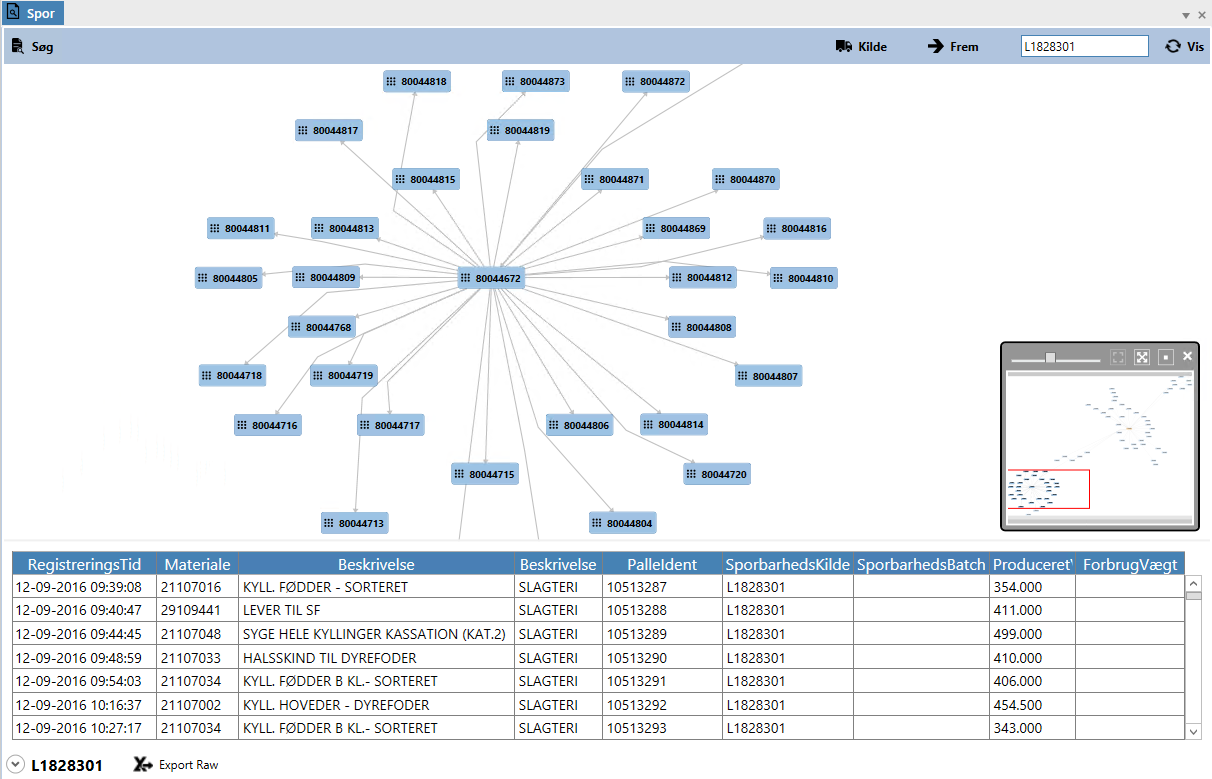

Quality Control, Food Safety and Traceabílity

As regulatory requirements and customer expectations for quality assurance become increasingly stringent, the process of ensuring compliance can be time-consuming. Often, the collection of quality control data is manual, with process data stored in paper files. Quality Process System (QPS) is a flexible data recording and monitoring module that integrates seamlessly into the modular ScanPlant NG design, enabling a more automated and cost-effective QC process. The QPS module can operate as a standalone system or be integrated into larger setups, such as trimming or deboning lines, as well as larger factory solutions.

Inspections can be directly linked to various production parameters, ensuring full traceability.

QPS can support the implementation of a comprehensive quality management system.

KEY BENEFITS- Efficient Data Collection: Streamline data collection compared to traditional paper-based systems.

- Integrated Production Data: QC data can be directly connected to production information such as lot or batch records.

- Unified Traceability System: Maintain a single, integrated traceability system, including QC data processing.

- Faster Access to Critical Data: Quickly retrieve essential data during a recall process or upon request from customers or regulatory authorities.

- Design Tool for QC Operations: Create and customize specific QC operations with ease.

- Define Inspections and Plans: Set up QC inspections and inspection schedules tailored to your needs.

- Industrial and Mobile Compatibility: Operate the system on industrial terminals and mobile devices.

- QC Scoring System: Calculate QC scores and trigger specific actions based on the output.

- Audit Trail: Maintain an audit trail with user ID and password for final approval of corrective actions and QC inspection results

By incorporating QPS into your operations, you can enhance compliance, improve traceability, and streamline quality assurance processes, ensuring you meet both regulatory and customer demands with greater efficiency

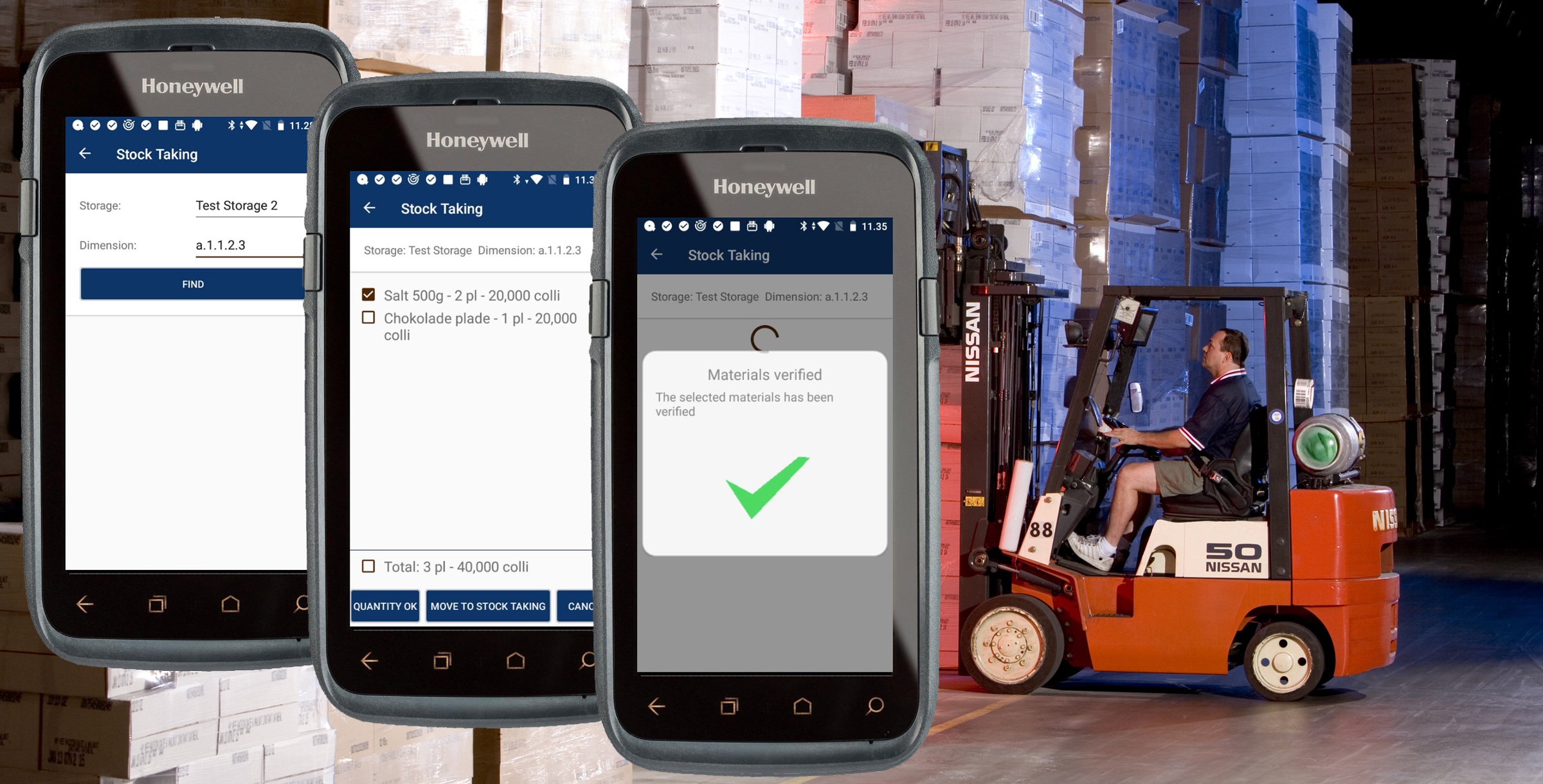

Warehouse Management

For many food producers, inventory management remains an area with room for improvement. Warehouses often contain a mix of fresh and frozen products, representing significant capital investments, which can lead to substantial losses if not properly managed. ScanPlant NG Inventory Control provides functionality to manage inventory down to the level of individual retail packages and up to the pallet level. ScanPlant NG Inventory Control allows for live-time management of products, assigning specific products to specific orders, “on-the-fly” stock-taking, manual or intelligent inventory allocation, and picking operations. The module supports all common types of inventory, including raw materials, work-in-progress, finished goods, and buffer stocks.

KEY BENEFITS

- ScanPlant NG Inventory allows you to easily manage and monitor all your inventories in one system.

- “On-the-Fly” Stock Take functionality enables more frequent stock counts, leading to more accurate inventory management.

- Real-time inventory management and monitoring with handheld devices, wall-mounted terminals, or PC screens.

- An alert system allows you to “push” information about products nearing expiration, preventing write-offs and losses due to product expiration.

- Intelligent inventory allocation and order picking ensure better and improved stock rotation, minimizing inventory losses (due to aging).

KEY FEATURES

- Packages, boxes, and pallets can be automatically or manually assigned to inventory.

- Inventory locations within storage units for racking systems (manual or automatic allocation).

- Full support for fully automated RFID-controlled buffer storage.

- Stock counts can be performed “on the fly,” and inventories adjusted based on results.

- Receive reminders for items in stock that are nearing their expiration date.

- A range of standard reports provides detailed information on what has been moved to and from storage, the status of the inventory, and the age of products in stock.

With ScanPlant NG Inventory Control, you can enhance the accuracy and efficiency of your warehouse operations, reducing losses and ensuring your products are always in the best condition for your customers.

Packing, Weighing and Labelling

In the food industry, the packaging process is one of the most common and critical stages, as it is the final point to “checkweigh” the product before it reaches its final destination—the customer. Additionally, this process is crucial for establishing the necessary traceability information and printing the customer-specific details required. ScanPlant NG Packing is a highly configurable and flexible module designed to manage packaging and labeling operations in real-time. By default, the module supports unique numbering of items and packages, ensuring full traceability.

KEY BENEFITS

- Comprehensive Management: Handle all types of product and package operations within a single system.

- Accurate Product Information: Record essential information about packaged products in compliance with customer requirements.

- Monitor and Report Efficiency: Track and report giveaway and throughput from batch to operator level, depending on the specific configuration.

- Reliable Traceability: Ensure quick and dependable response times for traceability in the event of a recall.

- Seamless Integration: Integrate with other ScanPlant NG modules, including Order Manager, Handheld Mobility for order picking and shipping, Quality Control, and Inventory Management.

KEY FEATURES

- Centralized Management: Centrally manage and collect data from all packaging stations.

- Wide Range of Equipment Support: Compatible with a variety of scales and terminals, from simple standalone scales requiring minimal operator input to advanced industrial terminals and automated solutions where operators can manage orders, pallets, and input various product parameters.

- Custom Label Printing: Print labels with specific packaging details such as production lot, production date, best before date, and more.

By implementing ScanPlant NG Packing, you can streamline your packaging process, enhance traceability, and ensure that all customer-specific requirements are met with precision and efficiency.