International search engine for Technology for Meat and Alternative Proteins

Status: Exhibitors of IFFA 2025

FRESH MEAT CUTTER FOR SLICING, DICING & SHREDDING

FRESH MEAT CUTTER FOR SLICING, DICING & SHREDDING

Description

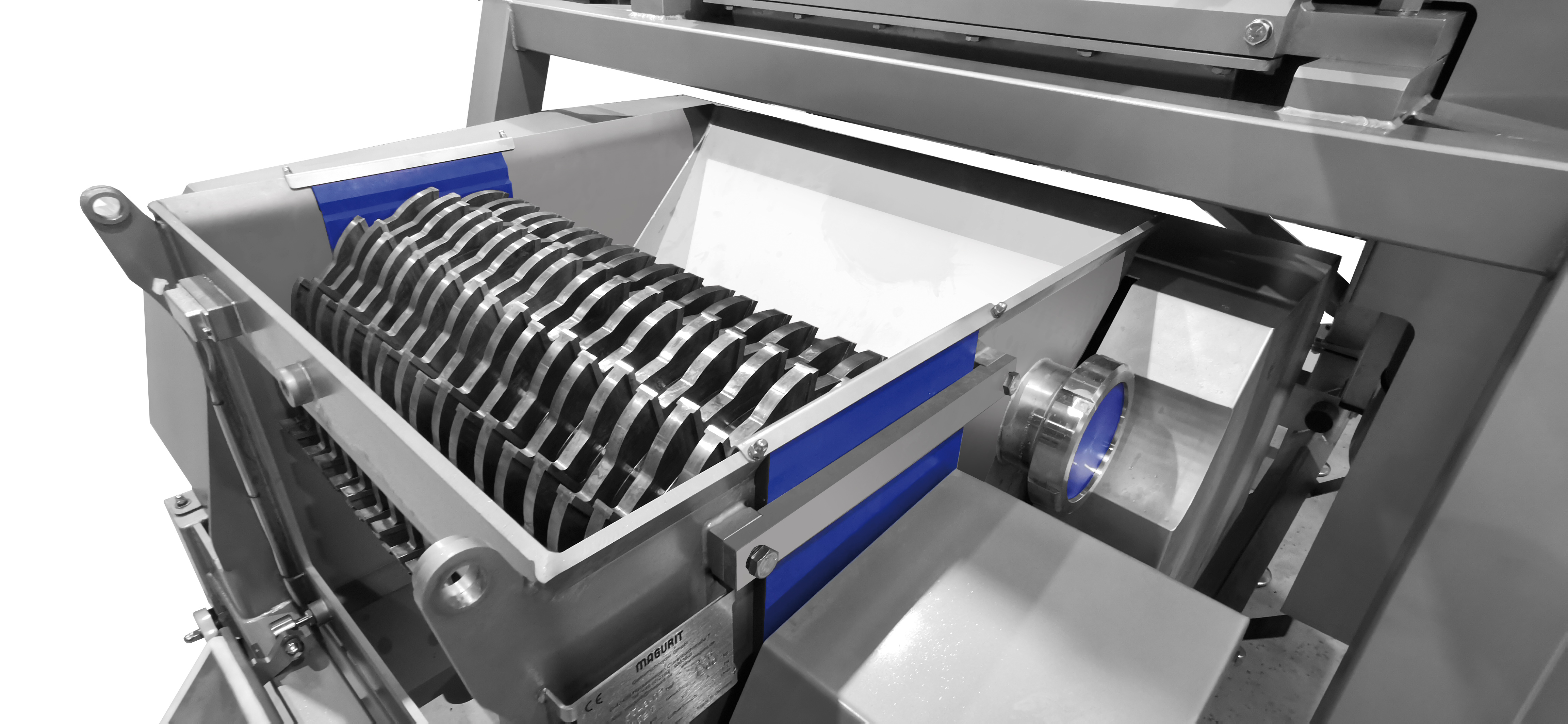

The machine series GALAN at MAGURIT includes all machines designed for continuous cutting of fresh products. Three models are available, depending on the raw materials, the necessary production volumes and the processing temperatures. In general it can be said that all 3 models GALAN 920, 930 and 960, are suitable for cutting raw, cooked, marinated, injected and also crust-fozen products.

GALAN 920 & 930 are also supplied as 3-dimensional cutter. Thus, slices, strips and cubes can be cut with one machine.

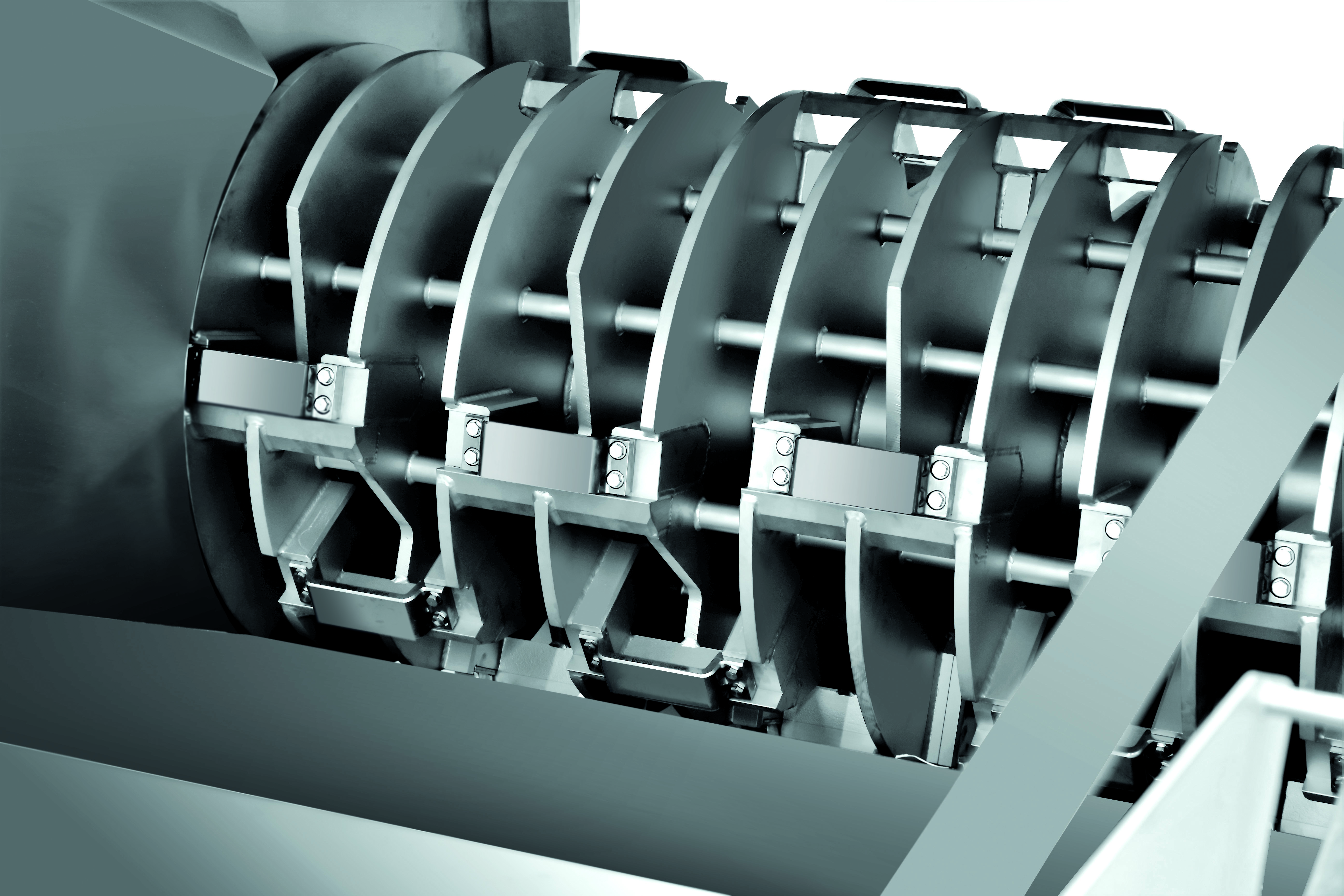

The product is placed manually or automatically onto a product infeed-conveyor belt and thus transported towards the cutting area. Continuously working scimitar blades perform the first dimension cut of the required piece size, which results from the speed of the belts in correlation to the rotation speed of the scimitar blades. Conveyor belt and scimitar blades are infinitely speed adjustable, allowing a change of cutting thickness in just a few moments. Due to the knife geometry, the scimitar blades achieve a clean, pulling cut, without squeezing and mechanical stress, as if cut by hand.

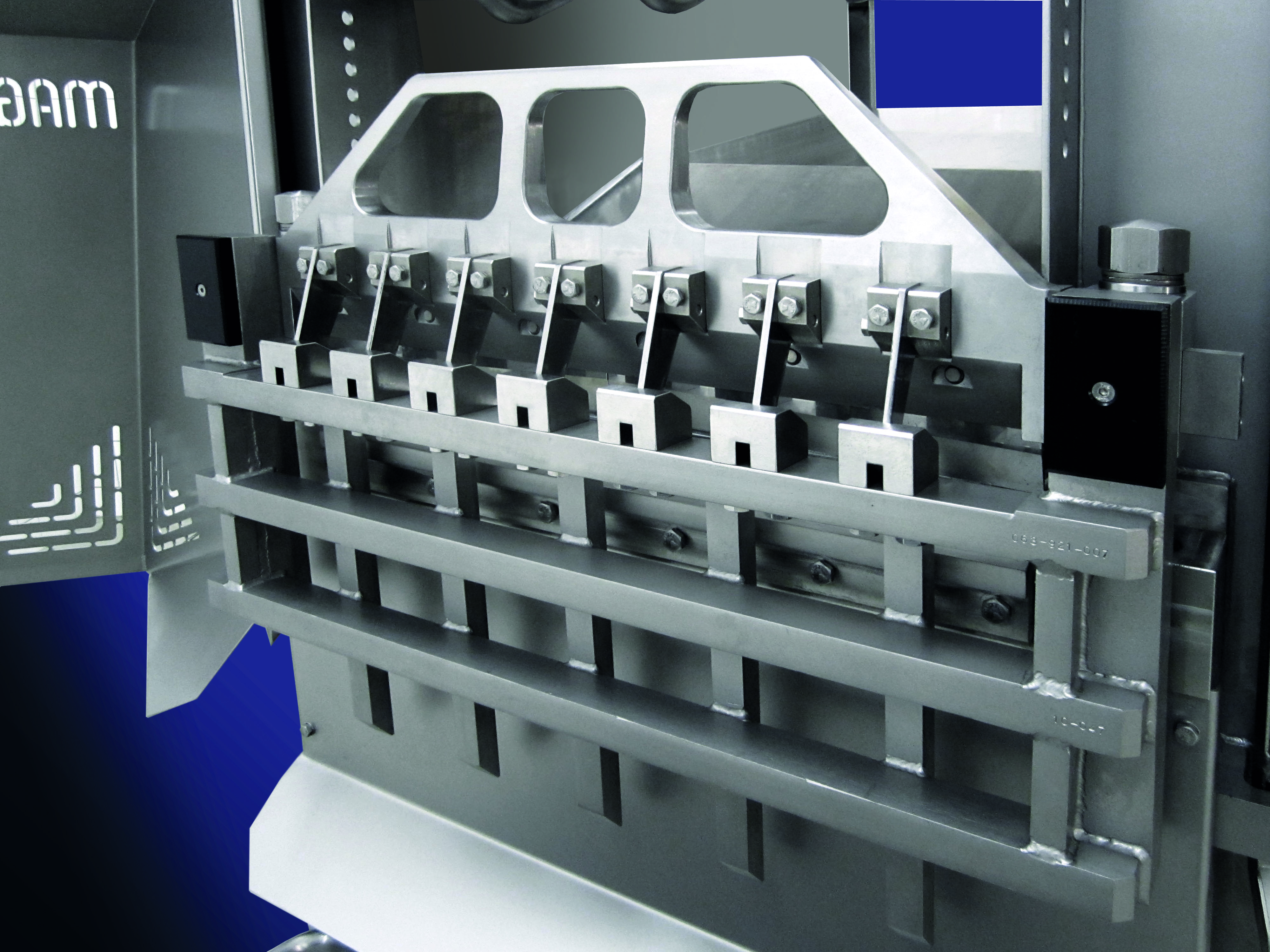

In a two-dimensional cut, i.e. when cutting strips or cubes, the product dips into the circular knife set which are mounted at 90° to the sickle blades. Circular knife sets are available from 4mm distance between the knives.

The product is fixed just before the cutting area by a hold-down above the conveyor belt. This hold-down guarantees a battery-friendly cut, since the product can no longer avoid the knives. The hold-down pressure is pneumatically and also infinitely adjustable, and adapts automatically to different product heights with the set pressure.

For optimal hygiene, the machines’ surfaces are sloping and thus allowing easy, quick cleaning.

- The compact GALAN 920, with 230mm (9 ") x 100mm (4") cutting chamber, is particularly well-suited for processing poultry and fish products since the raw material is i.a. not larger than the max. cutting chamber size is. Therefore, the blades of the GALAN 920 with 2 mm for the scimitar blades and 1 mm for the circular blades cut the raw material particularly gentle.

- The GALAN 930 is designed for, but not limited to, processing of high volumes of sturdy, stringy or harder products. But also softer and fragile products can be cut with GALAN 930. With a cutting area of 160mm (6 ¼”) x 360mm (14 ¼”) all common muscles can be cut, and the up to 4mm (5/32”) thick scimitar blades and the up to 2mm (5/64”) thick circular blades allow also the processing of very cold, even frozen products. Using different belt, scimitar-blade- and circular-blade-profiles the machine is adapted to our customers production needs.

- With a cutting width of 610mm (24 ") and a cutting height of 100mm (4"), the GALAN 960 is our largest GALAN model. It has been designed for integration into a continuous processing lines, e.g. in the connection of frying or cooling tunnels. Due to the cutting width, and thus the possible very high capacities that can be achieved, the GALAN 960 is always built with an integrated discharge belt for the cut product, so that continuous processing of the cut goods can be ensured. Of course the discharge belt also allows the discharge of the cut product into containers such as 200lt (400lbs), 300lt (600lbs) carriages or big-boxes, should a discontinuous process be preferred.

A unique feature of the GALAN 960 is that the machine offers the possibility of either separately collecting the abrasion generated during cutting in a collection box, or to discharge it with the cut product. Thus, depending on the product, the yield can be increased by up to 4%.

All 3 GALAN Modells can also be used as continues slicers, just cutting with the scimitar blades. The usually used circular balde sets can be replaced by a discharge conveyor that gets installed in the same position and is driven by the same motor as the circular blade sets. Especially cooked poultry but also raw meats can therewith be cut in slices of 3mm (1/8”) or thicker. Oprtionally the motor can be driven by a frequency converter, e.g. for separation of the individual slices.