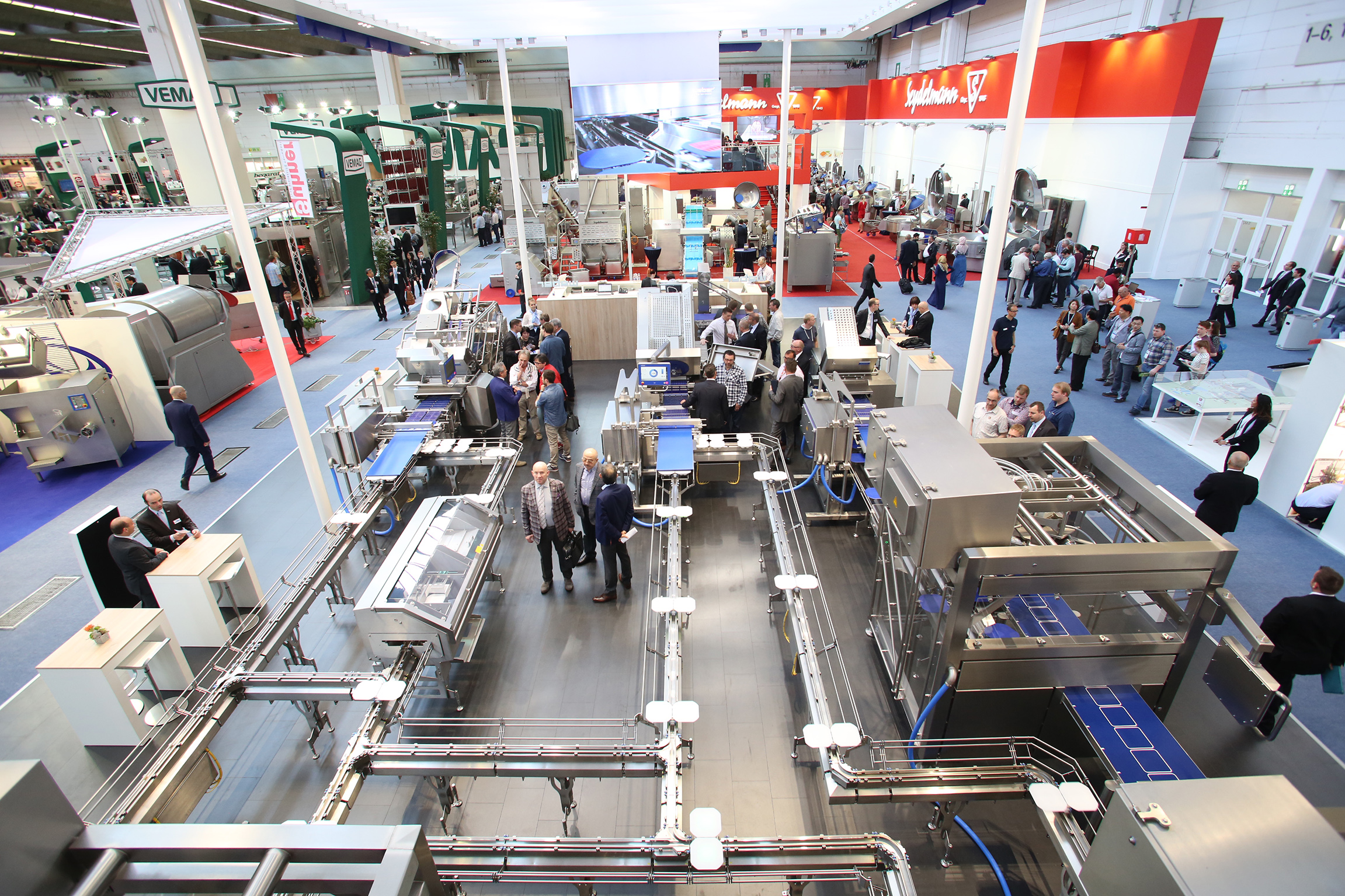

From 4 to 9 May, leading international companies will be showcasing their latest technologies at IFFA and providing information on the major trends and developments in the meat-processing industry. A considerable amount of space is devoted to the optimisation of production processes. The examples of best practice on show at the trade fair offer trade visitors a host of valuable hints in this regard, together with assistance in making relevant decisions.

Smart sensors – senses for the machines

In the ‘smart factory’, products and individual machines spread throughout the factory must communicate with one another and organise, regulate and monitor themselves. One of the basic requirements for this is the ready availability, at all times, of status data on products, machinery and drive mechanisms, bearings and so on. This task is undertaken by so-called ‘smart sensors’. As well as the actual sensor itself, which captures the magnitude of the relevant parameter, they include integrated micro-processors for processing and analysing the signals. Alongside traditional parameters such as temperature, power usage, torque and pressure, they also record gases and microbial contamination.

Paradigm shift in ‘condition monitoring’

Traditional maintenance at fixed intervals or at a given number of hours of operation usually takes place too early, for reasons of safety, and thus shortens unnecessarily the running time of still perfectly serviceable components such as drives, shafts and bearings. As a result, companies lose both money and valuable resources. Mechanical damage does not just appear from nowhere. It makes itself known well in advance with unusual noises, vibrations that suddenly appear, or temperature increases, as well as increased power consumption and the like. These changes can be picked up with the help of intelligent sensors in real time, monitored online and assessed, using appropriate CMS (Condition Monitoring Software). This makes it possible to target maintenance more specifically and provides valuable information on further possible optimisation of machinery and plant.

RFID chips provide a convincing electronic job ticket

RFID (Radio Frequency Identification) makes it possible to transmit data wirelessly in real time between transponders and read-write heads. Integral transponders in slaughtering hooks, feeding troughs, palettes, packaging or machine parts communicate bi-directionally with read-write heads installed at the processing and packaging stations. Thus, for example, not only do the factory-fitted RFID chips in the slicer knives store the geometrical data of the blades, they also store the sharpening schedules that go with them and the encoded item and serial numbers. The RFID read-write head installed in the sharpening module reads the data from the blade, identifies it, carries out the appropriate sharpening procedures and then updates the transponder data, including details of remaining serviceability. This principle can be applied to many other processes and procedures along the value creation change.

Visualisation systems make for efficiency, transparency and quality

The combination of digital camera and image-assessment software provide machines with the ability to see and, with it, open up the possibility of their reacting, in specific and appropriate ways, to changes in their environment and of taking decisions. As a result, they can recognise location, position, orientation, shape, size and colour of all sorts and kinds of object on conveyor belts. The data acquired in this way can then be used, for instance, to control robots and extraction/rejection units or to assess proportions of fat and lean in the in-line classification of bacon cuts as A, B or C class goods. Further applications include checking that packages are complete in number and undamaged, as well as the correct positioning and printing of explanatory and address labels.

More effective planning with a digital ‘twin’

A digital simulation is more than just a 1:1 digital representation of its physical counterpart. It possesses the same sensors, behaviours qualities and software, and is linked to other systems in exactly the same way. And that makes it the ideal development tool for designers and builders of plant and installations.

Typical areas where the principle can be used include virtual simulations of processes and functional testing of components, component modules, machines and, indeed, whole installations, including the control and application software. This enables designers to flag up and correct errors in advance of actual manufacture and saves costs, time, resources and energy. Professionals working in sales, planning, manufacture and maintenance, from both the manufacturing and consumer sides, can run through, discuss and optimise all the different options with the help of the digital ‘twin’, as if they were working in the real world. Other possibilities that arise as a result of digital simulation include training for future machine and plant operators and maintenance staff relating to both the system itself and the virtual commissioning system. And finally, the digital simulator can be used to operate and maintain the real plant and equipment in the real world. And this can be done across geographical borders, too.

IFFA will be opening its doors in Frankfurt am Main from 4 to 9 May 2019. All the signs augur well for the meat industry’s next leading international trade fair: more than 1,000 exhibitors from some 50 countries have already signed up to be part of this sector highlight. They will occupy a gross exhibition space of 120,000 square metres – eight per cent more than at the previous event. The inclusion of the new Exhibition Hall 12 has enabled IFFA to spread its wings and grow. At the same time, the trade fair is now concentrated at the western end of the Frankfurt Exhibition Centre for the first time, and thus offers an extensive and ground-breaking trade-fair experience.

Information and tickets at:

www.iffa.com

Press releases & images:

On the internet

Background information on Messe Frankfurt

Messe Frankfurt is the world’s largest trade fair, congress and event organiser with its own exhibition grounds. With over 2,500* employees at 30 locations, the company generates annual sales of around €715* million. Thanks to its far-reaching ties with the relevant sectors and to its international sales network, the Group looks after the business interests of its customers effectively. A comprehensive range of services – both onsite and online – ensures that customers worldwide enjoy consistently high quality and flexibility when planning, organising and running their events. The wide range of services includes renting exhibition grounds, trade fair construction and marketing, personnel and food services.

With its headquarters in Frankfurt am Main, the company is owned by the City of Frankfurt (60 percent) and the State of Hesse (40 percent).

Further information is available at: www.messefrankfurt.com

* provisional figures 2018

Download